52 Tall Sheets of Aluminum Gutter Roof Aluminium Composite Panel 1100 3003 PE PVDF Price Manufacture Pre Painted Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

We are able to supply 1,2,3,5,6,8 series alloy coil, foil and sheets, including 1***, 3***, 3104, 5052, 5182, 5754, 5083,5086,8011,8079

Our products include:

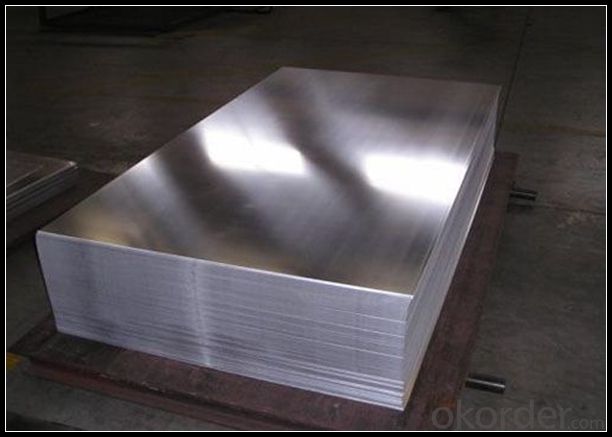

1). Mill-finished aluminum coil:

Alloy: AA1050, 1060, 1100, AA3003, 3005, 3015, 5052, 5754, 5083,8011 ,8079etc.

Temper: H14/16/18/22/24/32, HO etc.

Thickness: 0.08mm—100mm

Width: 100mm—2200mm (Can be slitted)

Notice: Embossment can be done if required.

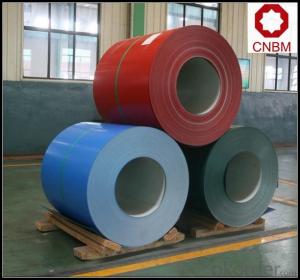

2). Color-Coated Aluminum Coil:

Alloy : AA1050/1100/3003/3005/3105/5005/5052/8079 etc.

Thickness: 0.03mm—1.50mm

Width: 10mm—1600mm (Can be slitted)

Coating : PVDF, PE

Coating thickness: Usually 16-25 micron, could be33-40 micron

Color : According to customers’ requirements

Notice : Embossment can be done if required

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc |

- Q: How do 101 aluminum sheets compare in terms of strength and durability?

- The strength and durability of 101 aluminum sheets can be evaluated based on their mechanical properties and performance characteristics. In terms of strength, 101 aluminum sheets possess moderate strength that is suitable for many applications. They have a tensile strength of around 27,000 psi (pounds per square inch) and a yield strength of approximately 21,000 psi. This indicates that they can withstand moderate amounts of stress and load without deforming or breaking. Durability-wise, 101 aluminum sheets have good resistance to corrosion, making them suitable for outdoor and marine applications. They are also highly resistant to various forms of weathering, including UV radiation and extreme temperatures. Their corrosion resistance is mainly due to the presence of a thin, protective oxide layer on the surface, which prevents further oxidation and ensures long-term durability. However, it is important to note that 101 aluminum sheets are not the most durable option available. They are not as strong or durable as some other aluminum alloys, such as 6061 or 7075, which have higher tensile and yield strengths. Hence, if a project requires exceptional strength or durability, it may be beneficial to consider using a different aluminum alloy. In conclusion, 101 aluminum sheets offer moderate strength and good durability, making them suitable for a wide range of applications. However, if the project requires higher strength or exceptional durability, it may be necessary to explore alternative aluminum alloys with superior mechanical properties.

- Q: Is it possible to utilize recycled aluminum to manufacture new items?

- <p>Yes, recycled aluminum can be used to create new products. Aluminum is highly recyclable, and the process of recycling it requires significantly less energy compared to producing aluminum from raw materials. Recycled aluminum maintains the same properties as new aluminum, making it suitable for a wide range of applications, from packaging to construction materials. The use of recycled aluminum helps reduce waste, conserve resources, and lower environmental impact.</p>

- Q: Are the aluminum sheets suitable for manufacturing architectural wall panels?

- Yes, aluminum sheets are suitable for manufacturing architectural wall panels. They are lightweight, durable, and can be easily shaped and formed into various designs. Additionally, aluminum is resistant to corrosion, making it suitable for outdoor applications.

- Q: Explain the distinction between aluminum sheets based on their thickness.

- <p>Aluminum sheets with different thicknesses primarily differ in their strength, weight, and applications. Thicker sheets offer greater strength and rigidity, making them suitable for structural applications or heavy-duty uses. In contrast, thinner sheets are lighter and more flexible, ideal for applications requiring formability or where weight is a concern, such as in the automotive or aerospace industries. The choice of thickness depends on the specific requirements of the project, including load-bearing needs, durability, and aesthetic considerations.</p>

- Q: What is the electrical conductivity of aluminum sheets?

- The electrical conductivity of aluminum sheets is quite high, as aluminum is known to be an excellent conductor of electricity.

- Q: Curtain wall aluminum plate reinforcement spacing between the number of appropriate, the country has no standard?

- As to the stiffener of the aluminum veneer, what are the following points?:1, aluminum reinforcement spacing is generally around 600mm, in order to ensure the aluminum plate in the positive and negative pressure conditions within the scope of deformation. When aluminum plate is welded, there is internal stress due to welding deformation (this internal stress can not be completely eliminated for a long time), and the rigidity of reinforcing bar should also be increased.2. The sectional dimension and spacing of stiffeners shall be determined according to the calculated wind pressure of the aluminum plate. But it is worth noting that the reinforcement calculation of single aluminum plate strengthening is different from the glass curtain wall, first, its strength is certainly no problem (still not seen the wind blowing broken plate, there is no joke) deflection possibility, bend off and windy weather also very few people to pay attention to the single aluminum plate plate surface after deformation the scenery. Therefore, the calculation of deflection of stiffeners are considered under the condition of wind strength and deflection when the winds of aluminum can cause permanent plastic deformation.In fact, aluminum veneer manufacturers generally use the single aluminum plate edge folding groove made of aluminum and 20*40*20, installed in the distance about 600mm. Also useful for profile (grooved aluminum) stiffenersThe spacing between stiffeners is very important to the cost of production. Generally speaking, the spacing of stiffeners will be changed from 600 to 350, and the cost will be increased by 8~15 yuan / square meter

- Q: Can aluminum sheets be used for sound insulation?

- Yes, aluminum sheets can be used for sound insulation to some extent. While aluminum is not the best material for soundproofing compared to others like rubber or foam, it can still provide some level of sound insulation when used correctly. Aluminum sheets can be installed as a barrier or partition in walls, ceilings, floors, or other surfaces to reduce the transmission of sound waves. However, it is important to note that additional soundproofing materials or techniques might be necessary to achieve optimal results.

- Q: How do you prevent fingerprints on aluminum sheets?

- To prevent fingerprints on aluminum sheets, there are a few strategies you can employ: 1. Wear gloves: One of the easiest ways to avoid leaving fingerprints on aluminum sheets is to wear gloves while handling them. This will create a barrier between your hands and the surface, preventing any marks or smudges. 2. Clean the surface: Before handling aluminum sheets, make sure to clean the surface thoroughly. Use a suitable cleaning agent or a mild detergent to remove any dirt or oils that may be present. Dry the sheets completely with a lint-free cloth to minimize the chances of fingerprints sticking to the surface. 3. Use a protective coating: Applying a protective coating on the aluminum sheets can help prevent fingerprints. There are several options available, such as clear lacquer or a clear protective film specifically designed for this purpose. These coatings create a barrier that reduces the visibility of fingerprints and makes them easier to clean off. 4. Handle with care: When handling aluminum sheets, try to touch them as little as possible. Fingerprints are more likely to occur when you apply pressure or touch the surface repeatedly. If possible, use tools or gloves to manipulate the sheets instead of direct contact with your hands. 5. Store properly: Proper storage of aluminum sheets is crucial in preventing fingerprints. Ensure that they are stored in a clean and dust-free environment, away from any potential contaminants. Consider using protective sleeves or covers to shield the sheets from fingerprints and other marks. By employing these preventive measures, you can significantly reduce the occurrence of fingerprints on aluminum sheets, keeping them clean and visually appealing.

- Q: heating can affect aluminium

- This is science so, if you want specific answers, you must ask specific questions. What type of aluminum are you interested in? What characteristics are important to you? What kind of factors are you talking about? You are right that heating can affect Al. In fact, heating affects, basically, everything, every material we know of and every physical and chemical process that we do and every process that happens in nature. Temperature is important in all of these. There are more than a hundred different commercial aluminum alloys and most of them are available in a variety of different tempers (heat treated conditions). The heat treatment of commercial Al alloys is a very important thing. If you want more specific information, consult your friendly neighborhood metallurgist.

- Q: Can aluminum sheets be used for chemical reactors?

- Yes, aluminum sheets can be used for chemical reactors. Aluminum is often chosen for its corrosion resistance, lightweight properties, and ability to withstand high temperatures, making it suitable for various chemical processes in reactor applications. However, it is important to consider the specific chemical reactions and conditions involved, as certain chemicals or extreme conditions may chemically react with or degrade aluminum.

Send your message to us

52 Tall Sheets of Aluminum Gutter Roof Aluminium Composite Panel 1100 3003 PE PVDF Price Manufacture Pre Painted Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords