GRP FRP Pipes Sea Water Pipe Series DN 700

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features & Benefits of GRP FRP pipe sea water pipe series

Corrosion-resistant

•Long, effective service-life materials

•No need for linings, coatings, cathodic protection, wraps or other forms of corrosion protection

•Low maintenance costs

•Hydraulic characteristics essentially constant over time

Light weight

(1/4 weight of ductile iron; 1/10 weight of concrete)

•Low transport costs (nestable)

•Eliminates need for expensive pipe handling equipment

Long standard lengths

(6, 12 metres)

•Fewer joints reduce installation time

•More pipe per transport vehicle means lower delivery costs

Extremely smooth bore

•Low friction loss means less pumping energy needed and lower operating costs

•Minimum slime build-up can help lower cleaning costs

Precision sealability

With elastomeric rubber rings

•Tight, efficient joints designed for bell & spigot to eliminate infiltration and ex-filtration

•Ease of joining, reducing installation time

• Accommodates small changes in line direction without fittings or differential settlement

Flexible manufacturing

•Custom diameters can be process manufactured to provide maximum flow volumes with ease of installation for rehabilitation

lining projects

High technology pipe design

•Lower wave celerity than other piping materials can mean less cost when designing for surge and water hammer pressures

High technology pipe manufacturing system producing pipe that complies to stringent performance standards (AWWA, ASTM, DIN, EN, etc.)

•High and consistent product quality worldwide which ensures reliable product performance

Control Testing of GRP pipe sea water pipe series

Raw Materials

Raw materials are delivered with vendor certification demonstrating their compliance with Zhongfu Lianzhong quality requirements. In addition, all raw materials are sample tested prior to their use. These tests ensure that the pipe materials comply with the specifications as stated

Physical Properties

The manufactured pipe’s hoop and axial load capacities are verified on a routine basis. In addition, pipe construction and composition are confirmed.

Finished Pipe

All pipes are subjected to the following control checks:

• Visual inspection

• Barcol hardness

• Wall thickness

• Section length

• Diameter

• Hydrostatic leak tightness test to 1.5 rated pressure (only PN6 and above)

On a sampling basis, the following control checks are performed:

• Pipe stiffness

• Deflection without damage or structural failure

• Axial and circumferential tensile load capacity

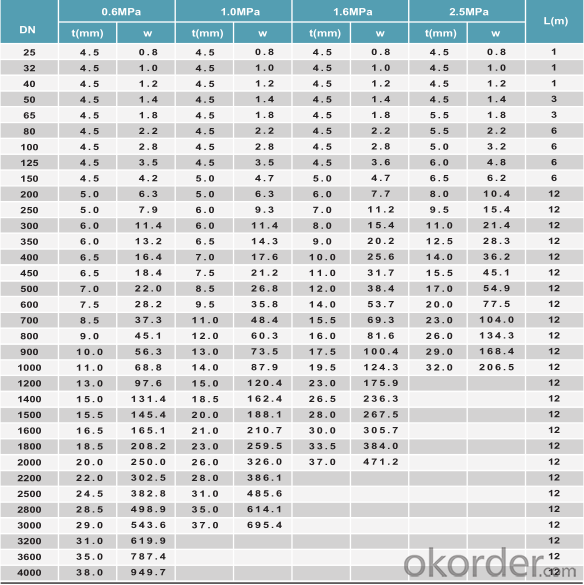

Thickness and Weight of Standard Pipes based on Internal Pressure of GRP pipe sea water pipe series

1. Internal liner (thickness 1.0 – 2.0 mm)

In tables bellow thickness include 1.5mm of liner and minimum pipe Stiffness 1250 Pa

2. Mechanical resistant layer in glass filament winding (based on internal pressure)

3. Top coat (0.2 – 0.3mm) . In tables bellow thickness include 0.2mm of top coat

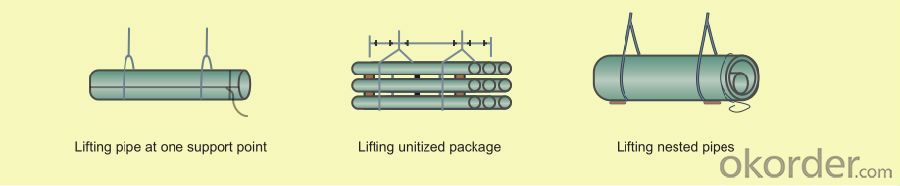

Unloading,Handling,Transportation and Storage of GRP pipe sea water pipe series

Unloading and Handling Pipes

Unloading the pipe is the responsibility of the customer. Be sure to maintain control of the pipe during unloading. Guide ropes attached to pipes or packages will enable easy manual control when lifting and handling. Do not drop, impact, or bump the pipe, particularly at pipe ends.

If at any time during handling or installation of the pipe, any damage such as a gouge, crack or facture occurs, the pipe should be repaired before the section is installed.

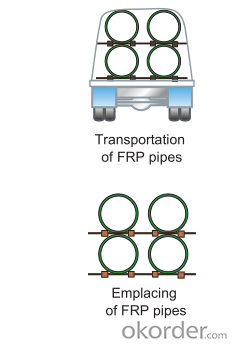

Transporting Pipes

Strap pipe to the vehicle over the support points using pliable straps or rope. Never use steel cables or chains without adequate padding to protect the pipe from abrasion. Bulges, flat areas or other abrupt changes of curvature are not permitted. Transport of pipes outside of these limitations may result in damage to the pipes.

Site Pipe Storage

It is generally advantageous to store pipe on flat timber to facilitate placement and removal of lifting slings

around the pipe.

When storing pipe directly on the ground, be sure that the area is relatively flat and free of rocks and other

potentially damaging debris. Placing the pipe on mounds of backfill material has been found to be an effective

way of site storing the pipe. All pipes should be chocked to prevent rolling in high winds.

FAQ of GRP pipe sea water pipe series

Q1: What’s the performance standards?

Lianzhong pipe is designed to meet all of these ASTM , AWWA, BS, DIN standards.

Q2: What’s the qualification testing for the products?

Lianzhong pipe has been rigorously tested to verify conformance to the ASTM D3262, ASTM D3517, AWWA C950 and DIN 16868 requirements

Q3: How long can I receive my goods?

A: Usually, we will deliver products within 20 days after the contract is signed. Delivery time is negotiable when necessary.

- Q: Is the installation of FRP pipes required qualification?

- Generally speaking, the glass steel pipe manufacturers will be installed for shipyard workers training, but if the shipyard did not ask, the training goal is to allow workers to master the skills to install, but they do not grant workers qualification certificate, but some shipyard will require workers engaged in installation with the installation qualification, so manufacturers will end in training workers to master confirmation the installation skills of workers, awarded the class approved qualification certificate. I don't know. Are you clear about that?.

- Q: FRP acceptance standard

- Check radial deflection values. In accordance with the requirements of the specification, the FRP pipe installation shall be completed within 24h, the initial radial deflection of the pipe shall be tested, and the pipe shall not be raised, flattened or otherwise mutated.

- Q: FRP duct material plan is how to mention?

- Process design according to user's requirements and choose what material to use. Then according to the drawings and process, calculate the amount of various materials. According to the delivery date and production schedule, you can write the material schedule.

- Q: Characteristics of FRP pipes

- The main pipe forming process of FRP is controlled by a computer for agricultural irrigation, as specified on the mandrel and tube glass fiber winding process the same manufacturing gel lining, according to design good linear and winding structure layer thickness, and the quartz sand and resin sand slurry mixed entangled in the structure layer. The outer protective layer. Raw and auxiliary materials: resin, short cut fiber, continuous glass fiber and quartz sand.

- Q: What are the disadvantages of glass fiber reinforced sand pipe?

- In brief, the disadvantage of FRP sand pipe is that the pipe is restrained by external environment, such as construction environment and span of support. Used in drinking water engineering, loess and sandy soil in the north are more suitable, but in ponds, marshes, mountains, then the pipeline backfill will increase the project investment. Used for overhead glass steel pipe lines, supporting the size of the gap is also the success or failure of the pipeline.

- Q: What is the difference between glass tube, sand pipe and glass tube?

- If the thickness of the pipe can meet the requirements of pressure, but can not meet the stiffness requirement, will choose to increase the thickness of sand to meet the stiffness (of course can not directly increase the sand thickness to meet the requirement of stiffness, but the cost is too high). Sand sandwiched glass fiber reinforced plastic pipes only have more than one sand sandwiched with glass fiber reinforced plastic pipes, and sand layer can be understood to replace glass fiber with quartz sand. The sand pipe with the same thickness is compared with the glass fiber reinforced plastic pipe, but the sand holding pipe is cheap, but the strength is poor; and the glass steel pipe is opposite.

- Q: How can I make up the broken glass fiber?

- Don't let the powder go. It is autumn, the temperature is low, so to put more than summer curing agent, as to the exact proportion, I just guess should be: curing agent, accelerator, resin; 1:1.5:8 with glass fiber wrapped around the pipe, coated on the glass fiber cloth to make glass steel with good quickly, let the glass steel the glass fiber cloth fully soaked, waiting for the full glass steel after curing, and then repeated several layers. It will be strong.

- Q: How is the glass reinforced septic tank and the cement drain pipe connected?

- The interface can be bonded with epoxy resin adhesive. The epoxy resin strongly adhere to the two materials, but the bonding surface must be clean.

- Q: How to connect glass fiber reinforced plastic sand pipe?

- The quality of the connection of glass reinforced plastic sand pipe pipe directly affects the quality of the pipeline. The connection forms between the pipes include 3 forms: socket, butt joint and flange connection.

- Q: What kind of epoxy resin and formula do you need for making fiberglass pipe?

- By explaining the materials, tools, moulds, renovation and repair, process, structure and various products, the latest development direction, process technology and application of FRP products are described.

Send your message to us

GRP FRP Pipes Sea Water Pipe Series DN 700

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords