Green Olive Net, Olive Harvest Net, HDPE Shade Net for Agriculture

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

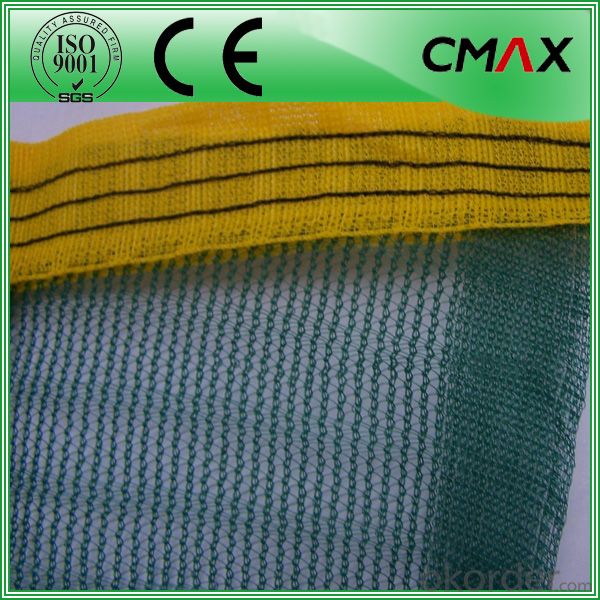

Green Olive Net, Olive Harvest Net, HDPE Shade Net for Agriculture

Production Description:

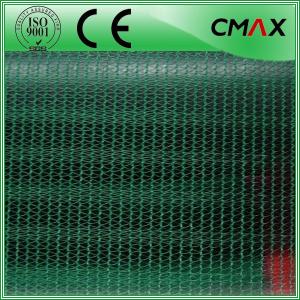

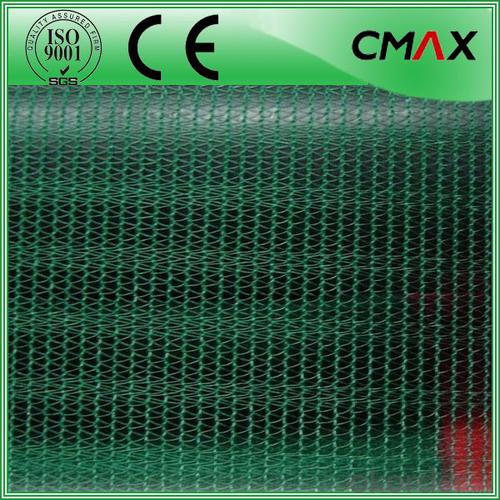

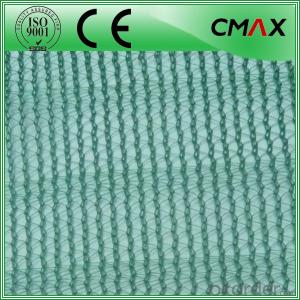

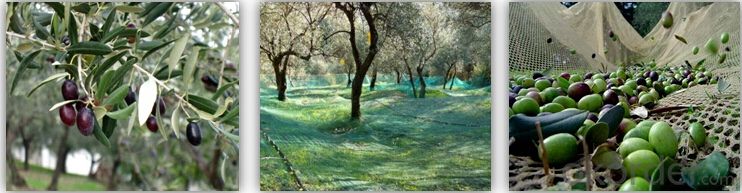

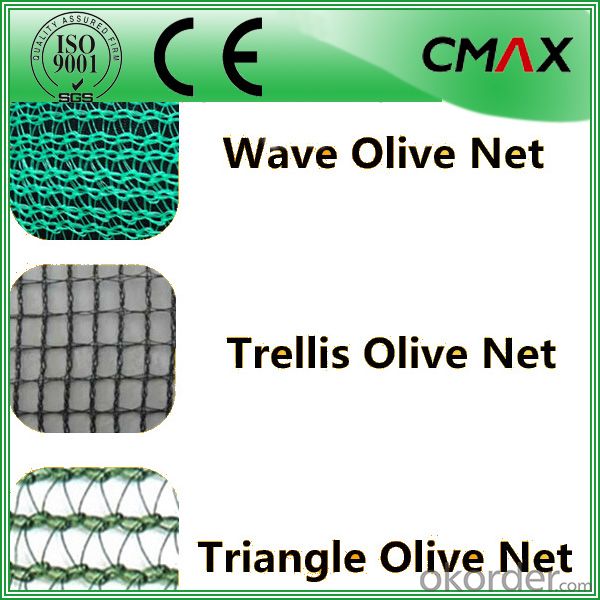

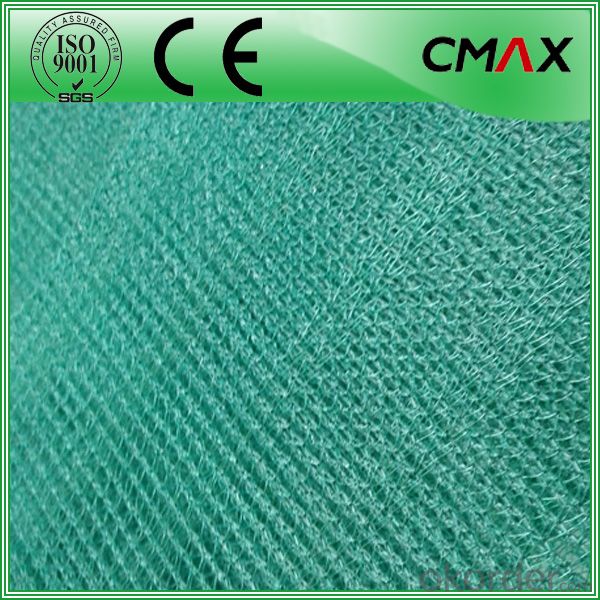

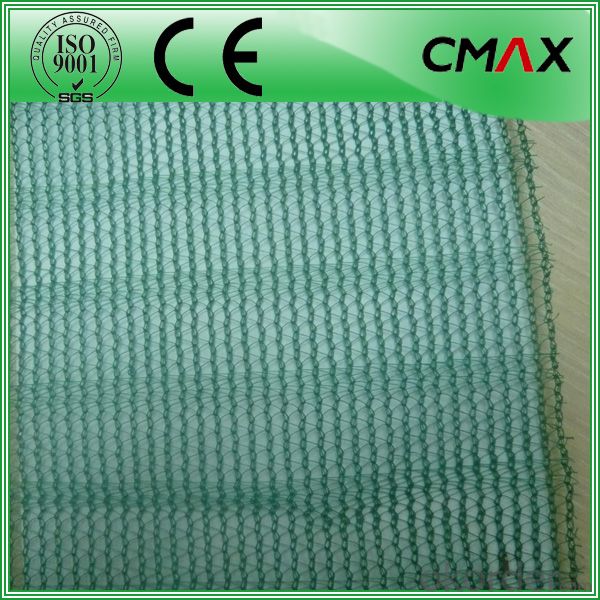

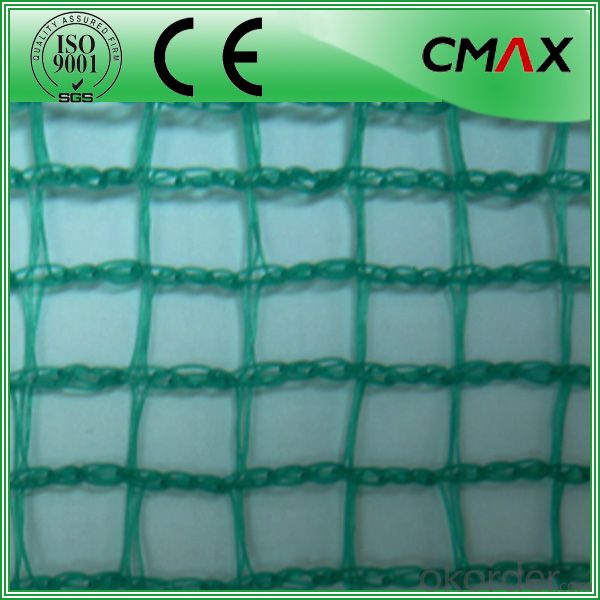

These nets are entirely made of UV stabilised polyethylene monofilament. The nets available have various kind of meshes in order to optimise the different harvesting methods of olives and fruits. Every net is suitable for a different application such as natural falling harvesting, hand harvesting or mechanised harvesting. The nets are available in different weights and colours and can be supplied in rolls or in sheets already stitched together with or without central vent.Olive collection net are used not only for the olive harvest, but also to gather chestnuts, nuts and deciduous fruits in general.

Produced with HDPE virgin material

UV stabilized - Long life

For Food : non-toxic, responsive to current European legislation on packaging for food.

Guarantee 5 years

Green&Black 50g/m2

Farmer used the net to gain olive from tree.

Specification:

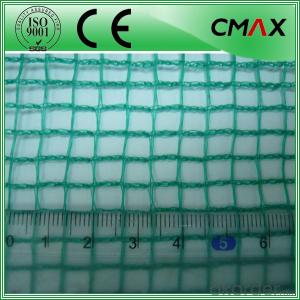

| Type | CMAX-Olive Net |

| Weight | 33-200 gsm |

| Color | Black, Green, Dark Green, etc |

| Width,Length | 1-6m, 50m,100m as your requirements |

| Raw material | 100% Virgin HDPE with U.V Stabilized and irganox |

| Using life | At least 4 years |

| Delivery time | 30 days after deposit |

| Specification | construction(/inch) Warp=3, Weft=4.5, Br.Str.(kg) ,Warp=10, Weft=2 ,Screening factor(%) :10% |

| Packing | rolls with PVC suare tube(5×5cm)/double folded/PE Stretch film/label |

| OEM | If you have your own packing design,we can quickly meet your requirments. |

Application:

Process:

Shipping&Packing:

Delivery Time: 20 Working Days After Confirmed P.O.

Packaging: Each piece packed in plastic bag, and several pieces per bale with PP woven bag outside, or in rolls with inner paper tube with plastic bag outside.

FAQ:

1.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Shanghai, China. You can take flight to Shanghai Hongqiao airport, and 25 mins reach to our factory.

2.Q:What is the material of your products?

A: We use the raw material of High Density Polyethylene (HDPE) with UV Stabilized & Igranox to make our netting

3.Q:How does your factory do regarding quality control?

A: we are very proud to let you know that , We use the best raw material , have at least 5years experienced workers,

the advanced machine and specialized team to assure the quality

We perform Quality Control inspections on 100% of our products.

Our inspection standards are strictly in accordance with the ISO9001 certification system.

- Q: A large number of polyethylene particles, good color

- English Name: PolyethyleneSpecific gravity: 0.9-0.91 g / cubic centimeter molding shrinkage: 1.0-2.5% molding temperature: 160-220 DEG C drying conditions:

- Q: How does agricultural plastic affect nutrient management?

- Agricultural plastic can have both positive and negative effects on nutrient management. On one hand, plastic mulch can help conserve soil moisture, control weed growth, and increase crop yields, thereby contributing to improved nutrient management. It can also prevent nutrient leaching by acting as a barrier between the soil and the atmosphere. On the other hand, improper disposal of agricultural plastic can lead to environmental pollution, including the release of harmful chemicals into the soil and water bodies. Therefore, proper handling and recycling of agricultural plastic are crucial to minimize its negative impact on nutrient management.

- Q: I want to buy another fish tank. I found a 60 gallon for $100. but it's plastic, is that okay?

- As long as it's holds about 80l of water it doesn't matter that it's made from. An 80litre tank is about 60cm long if you aren't good with tank sizes. Some of the very large and expensive tanks are made from plastic.(expensive acrylic). BUT, many of those cheap plastic tanks are simply too small for ANY fish, especially large messy ones like goldfish. I suspect what you are calling a Large tank is one I would consider Small? If you can't afford a decent size tank then I have 2 suggestions. Look for a 2nd hand tank. It need not be fancy, it just needs to hold water, and have a decent filter, which you can buy separately if needed. Everything else is optional. OR: Consider smaller fish. Most will need a heater, betta, guppies etc, but White Cloud Minnows are happy at room temperature and can live in smaller tanks. Ian Edit: The problem with those is they ARE way too small for goldfish, or most fish for that matter. the BIG size is only 12litres, my Smallest tank is 18l, and I would only keep a betta or a couple of guppies in that. Don't waste you money on those, save and get a bigger tank, your fish will live MUCH longer

- Q: How are plastic plant labels used in horticulture?

- Plastic plant labels are used in horticulture to provide important information about plants, such as their names, care instructions, and other relevant details. These labels are typically inserted into the soil near the plants, helping gardeners and horticulturists keep track of different species, organize their garden, and easily identify plants. They are also helpful for nurseries and plant sellers to provide information to customers, ensuring that the right care is given to each plant.

- Q: What are some health risks of drinking from plastic bottles vs. glass bottles. Also, what are some pollution risks of anything plastic...Thanks in advance!

- Health Risks 1. Chemical Erosion of the Plastic due time and chemical reactions (UV radiation, action of water,etc). It's partially nonbiodegradable, so some of chemical residue leaks and it is potentially poisonous (So disposable plastic drinking container use it once and don't used them). 2. Pain in Kidney (Renitis and Glomerulititis). Poisonous High-Denisty Polymer damages glomerules and Bowman's Capsule. 3. Yellowing of your skin. 4. Gastrointestal Disturbance. 5. Neurorelated Diseases. Pollution Risks 1. Increase of Biodiversity Degradation, because plastics are generally nonbiodegradable. Species eat them and they die. Affect greatly in the food chain and it creates biological magnification/ amplification (poisons carry within the food chain). 2. When incinerated it create dioxin. 3. Land Pollution/ Water Pollution/ Air Pollution.

- Q: Plastic is used to make:- bags- bottles- yogurt pots- cutlery- cling film- plates- cups- margarine tubs- microwave meal trays- bin linersBut why is the material plastic used?

- Plastic is used because its light and hard wearing. It can have many different properties! therefore it can have all the positive attributes of metal, hard-wearing, strong, durable (eg. Kevlar) but is much lighter. as well as this it is waterproof and cheap to produce. Hope that Helped :)

- Q: Can nursery trays be used for growing mosses?

- Yes, nursery trays can be used for growing mosses. Mosses are low-maintenance plants that do not require deep soil, so nursery trays can provide a suitable environment for their growth. The shallow compartments of the trays allow for proper water drainage and air circulation, which are important for mosses to thrive. Additionally, nursery trays can be easily moved and arranged to create different moss arrangements, making them a convenient option for moss cultivation.

- Q: i am doing a project on plastic bottles and was wondering what the advantages of recycling plastic bottles are and the disadvantages? and what is better for the environment plastic bottles or glass bottles and why?

- Water bottles currently make up about two percent of landfill waste. Some environmentalists believe it can take plastic bottles up to 1,000 years to decompose. Although there is no definite time frame, it does take a long time for plastic bottles to decompose. If they are sitting in landfills sealed and compacted with all of the other trash and bottles with no air moving, they won't decompose at all. Plastic is actually outweighing plankton in the sea. That means that almost all of our seafood contains plastic They are also a danger to plants animals who eat them or get them stuck on body parts Then there is the fact that plastic bottle contain BPH which acts contrary to human health.

- Q: What are the best ground cover plants for attracting birds?

- Some of the best ground cover plants for attracting birds include creeping thyme, creeping juniper, creeping phlox, and sedum. These plants not only provide shelter and nesting areas for birds, but also offer berries, seeds, and nectar as a food source.

- Q: How do agricultural plastic products help with plant disease management?

- Agricultural plastic products help with plant disease management by creating a physical barrier that prevents the spread of pathogens, reducing the risk of infection. Additionally, plastic mulch can regulate soil temperature and moisture, creating an unfavorable environment for disease-causing organisms.

Send your message to us

Green Olive Net, Olive Harvest Net, HDPE Shade Net for Agriculture

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords