Grade ASTM A36 Carbon Steel Round Bar with High Tensile

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade ASTM A36 Carbon Steel Round Bar with High Tensile

Details of Grade ASTM A36 Carbon Steel Round Bar with High Tensile

Name | Steel Round Bar |

Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of Grade ASTM A36 Carbon Steel Round Bar with High Tensile

| Product name | ASTM A36 carbon steel round bar |

| Dimensions | 15-150mm |

| Length | 6-12m |

| Standard | ASTM,BS,GB,JIS |

| Grade | Q195 Q235 20# 45# A36 SAE1020 |

| Brand | CNBM |

| Application | Mild Steel Round Bar is used for making security grills, screens, Construction and Machine Manufacture. |

| Finish condition | hot rolled |

| Appearance | new |

| Sales mode | factory direct sales |

| Quality assurance | mill test certificate is provided, third party inspection is acceptable |

| Trade term | FOB/CIF/CFR |

| Payment term | 30%T/T in advance, balance against B/L copy;Sight irrevocable LC |

| Delivery time | Within 15-30 days after receiving original LC or deposit, also according to the quantity |

| Certification | ISO9001:2000/BV |

| Product name | ASTM A36 carbon steel round bar |

| Dimensions | 15-150mm |

| Length | 6-12m |

| Standard | ASTM,BS,GB,JIS |

| Grade | Q195 Q235 20# 45# A36 SAE1020 |

| Brand | CNBM |

| Application | Mild Steel Round Bar is used for making security grills, screens, Construction and Machine Manufacture. |

| Finish condition | hot rolled |

| Appearance | new |

| Sales mode | factory direct sales |

| Quality assurance | mill test certificate is provided, third party inspection is acceptable |

| Trade term | FOB/CIF/CFR |

| Payment term | 30%T/T in advance, balance against B/L copy;Sight irrevocable LC |

| Delivery time | Within 15-30 days after receiving original LC or deposit, also according to the quantity |

| Certification | ISO9001:2000/BV |

CNBM Introduction of Grade ASTM A36 Carbon Steel Round Bar with High Tensile

| Product name | ASTM A36 carbon steel round bar |

| Dimensions | 15-150mm |

| Length | 6-12m |

| Standard | ASTM,BS,GB,JIS |

| Grade | Q195 Q235 20# 45# A36 SAE1020 |

| Brand | CNBM |

| Application | Mild Steel Round Bar is used for making security grills, screens, Construction and Machine Manufacture. |

| Finish condition | hot rolled |

| Appearance | new |

| Sales mode | factory direct sales |

| Quality assurance | mill test certificate is provided, third party inspection is acceptable |

| Trade term | FOB/CIF/CFR |

| Payment term | 30%T/T in advance, balance against B/L copy;Sight irrevocable LC |

| Delivery time | Within 15-30 days after receiving original LC or deposit, also according to the quantity |

| Certification | ISO9001:2000/BV |

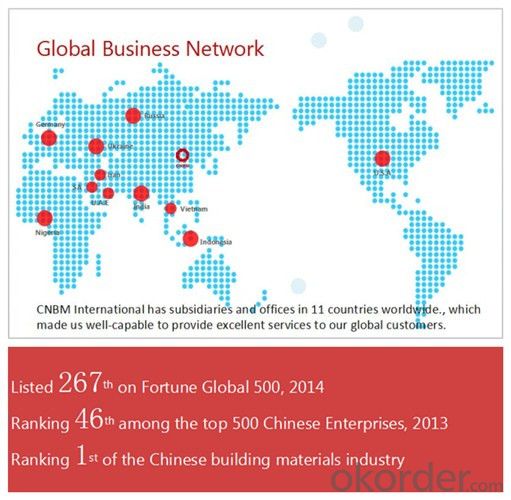

CNBM Introduction of Grade ASTM A36 Carbon Steel Round Bar with High Tensile Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery Grade ASTM A36 Carbon Steel Round Bar with High Tensile

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does special steel perform in oil and gas applications?

- Special steel is highly desirable and widely used in oil and gas applications due to its exceptional performance and superior properties. Special steel exhibits excellent resistance to corrosion, which is crucial in environments where oil and gas are present. This resistance to corrosion helps prevent equipment failure and ensures the longevity and reliability of the components. Moreover, special steel possesses high strength and durability, making it suitable for withstanding extreme conditions, such as high pressure and temperature. This strength allows the steel to withstand the demanding and harsh environments that oil and gas applications often present. Additionally, special steel can retain its mechanical properties even at elevated temperatures, providing stability and reliability in these challenging conditions. Another significant advantage of special steel is its excellent weldability. This property allows for easy fabrication and assembly of components, reducing production time and costs. It also ensures the integrity of the structures and equipment used in oil and gas applications. Furthermore, special steel offers exceptional resistance to fatigue and wear, which are common concerns in oil and gas operations. The ability of special steel to withstand cyclic loading and abrasive conditions ensures the longevity and reliability of the components, reducing maintenance and replacement costs. Overall, special steel performs exceptionally well in oil and gas applications due to its corrosion resistance, high strength, durability, weldability, and resistance to fatigue and wear. Its superior properties make it a preferred choice for critical components, ensuring the efficiency, safety, and reliability of oil and gas operations.

- Q: What are the common challenges in welding titanium alloys?

- Some common challenges in welding titanium alloys include its high reactivity with oxygen, the formation of brittle intermetallic compounds, the need for precise temperature control due to its low thermal conductivity, and the potential for distortion or warping during the cooling process.

- Q: What are the future trends in special steel manufacturing?

- The future trends in special steel manufacturing are likely to focus on advancements in technology, sustainability, and the development of new alloys. Firstly, technology will play a significant role in shaping the future of special steel manufacturing. Automation and robotics are expected to be increasingly integrated into the production process, leading to improved efficiency, precision, and reduced labor costs. This will also allow for better quality control and the ability to produce more complex and customized steel products. Secondly, sustainability will be a key focus in special steel manufacturing. As the world becomes more environmentally conscious, companies are seeking ways to reduce their carbon footprint. This includes employing cleaner production methods, such as using renewable energy sources and implementing recycling programs to minimize waste. Additionally, there will likely be a shift towards developing greener alloys with reduced environmental impact. Furthermore, the development of new alloys will be crucial in meeting the evolving needs of various industries. With advancements in material science, special steel manufacturers will be able to create alloys with enhanced properties, such as increased strength, durability, corrosion resistance, and heat resistance. These new alloys will cater to the growing demand for high-performance materials in sectors like aerospace, automotive, energy, and construction. Moreover, the future of special steel manufacturing is also likely to be influenced by the increasing demand for lightweight materials. As industries strive to improve fuel efficiency and reduce emissions, there will be a need for special steel alloys that offer high strength-to-weight ratios. This will drive research and development efforts towards creating lighter yet stronger steel products. In conclusion, the future trends in special steel manufacturing will revolve around technological advancements, sustainability, and the development of new alloys. These trends will shape the industry, bringing about increased automation, cleaner production methods, and the creation of innovative alloys to meet the changing needs of various sectors.

- Q: How is high-speed stainless steel used in the production of machining tools?

- High-speed stainless steel is used in the production of machining tools due to its excellent hardness, wear resistance, and heat resistance properties. It allows the tools to operate at high speeds without losing their shape or deteriorating quickly. The stainless steel's corrosion resistance also ensures the longevity of the machining tools, making them suitable for various industrial applications.

- Q: How does special steel contribute to the aerospace material recyclability?

- Special steel contributes to aerospace material recyclability in several ways. First, special steel is known for its high strength-to-weight ratio, making it a preferred choice for critical components in aircraft. This means that when these components reach the end of their service life, they can be recycled and repurposed without compromising the safety and structural integrity of the aircraft. Additionally, special steel is highly durable and resistant to corrosion, making it suitable for long-term use in harsh aerospace environments. This durability ensures that the steel can be recycled multiple times without significant degradation in its mechanical properties, further enhancing the recyclability of aerospace materials. Moreover, the metallurgical properties of special steel allow for efficient recycling processes. Steel is a highly recyclable material, and special steel alloys can be easily separated from other materials during the recycling process. This ease of separation and the high value of steel in the recycling market make special steel an economically viable choice for aerospace manufacturers and recyclers. In summary, special steel's strength, durability, corrosion resistance, and ease of recycling make it a valuable contributor to the recyclability of aerospace materials. By using special steel in aircraft components, the aerospace industry can enhance sustainability efforts and reduce the environmental impact of its operations.

- Q: Can special steel be used in railway applications?

- Yes, special steel can be used in railway applications. Special steel, such as high-strength steel or corrosion-resistant steel, can offer enhanced durability, strength, and resistance to wear and tear in railway components, tracks, and infrastructure. This allows for safer and more efficient railway operations.

- Q: What are the main characteristics of structural steel forgings?

- Structural steel forgings offer numerous advantageous qualities that make them highly suitable for a wide range of construction and engineering purposes. To begin with, the outstanding strength and durability of structural steel forgings are among their main attributes. Steel possesses remarkable tensile strength, allowing it to bear heavy loads and withstand stress-induced deformations. This makes structural steel forgings ideal for supporting large structures and withstanding dynamic forces such as wind or seismic activity. Another noteworthy quality is the versatility of structural steel forgings. Steel can be shaped and sized into a diverse array of forms, making it adaptable to various design requirements. It can be forged into intricate and complex shapes, enabling the creation of precise and customized components. This versatility enables the application of structural steel forgings in a multitude of scenarios, ranging from beams and columns in buildings to bridges and offshore structures. Moreover, structural steel forgings exhibit excellent weldability. Various welding techniques can be employed to easily join steel components together, creating robust and dependable connections. This enhances the overall structural integrity and longevity of steel elements. One more key characteristic of structural steel forgings is their cost-effectiveness. Steel is an economical construction material due to its abundance, recyclability, and ease of manufacturing. The production process for steel forgings is efficient and can be scaled up to meet the demands of large-scale construction projects. Consequently, it represents a cost-effective choice for numerous applications. Furthermore, structural steel forgings are renowned for their resistance to corrosion. Steel can be treated with coatings or alloys to enhance its resistance against rust and other forms of corrosion. This makes it highly suitable for deployment in environments with high humidity, exposure to saltwater, or harsh weather conditions. In conclusion, the exceptional strength, versatility, weldability, cost-effectiveness, and resistance to corrosion are the primary characteristics of structural steel forgings. These qualities position structural steel forgings as the preferred choice for a multitude of construction and engineering applications, offering durability, reliability, and longevity to structures.

- Q: How is the toughness of special steel measured?

- The toughness of special steel can be assessed by specific tests and methodologies that evaluate its capacity to absorb energy and withstand fractures. One widely used approach is the Charpy V-Notch (CVN) test, in which a notched specimen is struck by a pendulum hammer, and the energy absorbed during fracture is measured. The results are then expressed as the energy absorbed per unit area, typically in joules per square centimeter (J/cm²) or foot-pounds per square inch (ft-lb/in²). Another commonly employed test is the Izod test, which is similar to the CVN test but involves a different specimen geometry. Furthermore, engineers and manufacturers may also employ other mechanical tests such as tensile strength, impact strength, and fracture toughness measurements to evaluate the toughness of special steel. These tests are invaluable in determining the suitability of special steel for various applications, particularly those requiring exceptional resistance to impact or sudden loading.

- Q: Can special steel be used in tool manufacturing?

- Yes, special steel can be used in tool manufacturing. Special steel is often preferred for tool manufacturing due to its exceptional hardness, toughness, and resistance to wear and corrosion. These properties make it highly suitable for producing durable and efficient tools that can withstand demanding applications.

- Q: Can special steel be used in the defense industry?

- Yes, special steel can be used in the defense industry. Special steel, such as high-strength steel or armor-grade steel, possesses unique properties that make it suitable for various defense applications. It can be used for manufacturing military vehicles, aircraft components, body armor, ballistic plates, and other defense equipment that require enhanced strength, durability, and resistance to extreme conditions. Special steel's ability to withstand impacts, provide protection against projectiles, and maintain structural integrity makes it an essential material in the defense industry.

Send your message to us

Grade ASTM A36 Carbon Steel Round Bar with High Tensile

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords