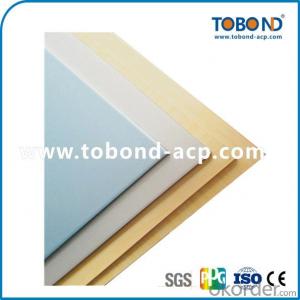

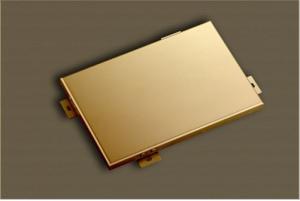

Golden mirror acp / TOBOND aluminum composite panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TOBOND PVDF ALUMINIUM COMPOSITE PANEL

TOBOND PVDF plus Aluminium Composite Panel is special metal surface wall cladding material, compounded with superior aluminum and LDPE Plastic.

Comparing to traditional metal panel, TOBOND ACP is with prime performance of economic efficiency, environment friendly and flexible installation.

ADVANTAGES OF TOBOND ACP

High strength, easy maintenance, 20 years not color fade.

Easy fabrication and installation.

Good Impact Resistance.

Light weight and rigid, reducing buildings load, good performance for quakeproof.

Good Smoothingness.

Various color and size for option.

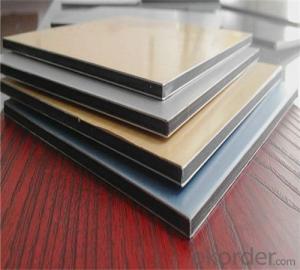

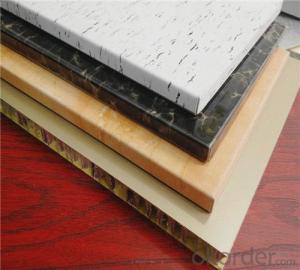

STANDARD SIZE OF ACP

Series | Coating | Usage | Panel Thickness | Panel Size(mm) |

PVDF Plus Outdoor Panel | PVDF | Exterior Wall Cladding | 4mm /3mm | 1220*2440 1220*2900 |

Indoor panel | Polyester | Interior Decoration/ Advertisement board | ||

Fireproof panel | PVDF/Polyester | Exterior Wall Cladding/Interior Decoration | ||

Special Size For Option | 6mm/5mm | 1250*2900 1500*2900 1500*5800 | ||

Proceeding Noticed

Portage: panel must be uplifted with its four borders at the same time during portage, do not drag and whop for fear scraping surface of the panel.

Storage: panel must be stored in cool dry place, and placed on flat surface.

Arcing Machining: using professional bending equipment to machining, forcing inchmeal to make the panel reaching bending radian needed. Do not bending one-off.

Batch: same color panel from different batches may have chromatic aberration, contrast process of chromatic aberration should be added if selling or using panels with different batches panels. Panels can be placed on a plane only there may be visual chromatic aberration.

Installation direction: panels must be install in same direction.

Ripping film: the protective film should be ripped away within 45 days after installation, to avoid survivors left.

- Q: I stood a piece of the shop when the remaining aluminum-plastic plate plate, this aluminum layer even so, is auspicious brand, this is the situation, I do the store will fall off

- All over the name of this brand is the name of the aluminum-plastic plate.

- Q: Who prawn know that there is no aluminum plate factory in Shenyang it? What is the best brand and contact phone, thank you first, huh, huh

- As of today, did not hear Shenyang aluminum plate manufacturers

- Q: How to separate the aluminum alloy on the aluminum plate

- Are there any aluminum alloy on aluminum? If so, is also sticky, cut it! If the whole, or destroyed the aluminum-plastic plate, or destroyed the aluminum!

- Q: Roof by the wood core board base, do the slope; paste the ordinary aluminum-plastic plate, leaving 0.4cm seam, sealed with structural adhesive, after a winter, structural plastic cracks, causing multiple water leakage, some time ago to make up the seal Glue, the problem is not completely resolved. Will you prawn: If you do a waterproof above, how should construction treatment?

- It is recommended to choose a good brand of weathering sealant to fill cracks waterproof. Brand recommended options: new exhibition, white clouds, silicon treasure, the river, Dow Corning, Maxima, gold leaves and so on. The cracks appear to remove the tape, with xylene or ether scrub clean the location of the tape, and other scrubbing liquid marked with weathering sealant.

- Q: I am in Kunming, but there is a site in OKorder side, want to buy aluminum plastic plate to decorate the store, there is no authentic aluminum plate manufacturers ah

- Kunming Yulong Road, there is a way to sell aluminum-plastic plate, you can ask

- Q: White aluminum plate can be a new brush color? Store white aluminum-plastic board for a long time dirty, you can buy a new paint back to brush it?

- Aluminum-plastic plate is divided into inner wall panels, external wall panels, wood plate, Gang plate, fire board five categories, a total of hundreds of different specifications of different colors of the plate;

- Q: Kitchen ceiling with aluminum or aluminum plate is good? Which brand in Jinan, the higher cost?

- Now the kitchen ceiling is mostly hanging aluminum plate, is the integrated ceiling, upstairs that aluminum-plastic ceiling ceiling per square cost of about 60-70 yuan is not down, I am a carpenter, do aluminum plate ceiling light wages are To 50 yuan a square, there are materials, aluminum plate a medium 80 yuan a, a 2.88 square, but also with 9% rendering, but also Wan Nengjiao, keel, glass glue, nails, Medium material with a piece of material almost 150 yuan a square, but also freight, aluminum buckle board more convenient to buy the place there are installed workers,

- Q: OKorder where to buy aluminum panels, aluminum veneer, aluminum honeycomb panels sun panels, artificial stone countertops, translucent slate, Shu Le homes

- OKorder nobody doing aluminum honeycomb board to do these most famous is Foshan, Guangdong you can ask me

- Q: Chengdu Deyang made of external walls of aluminum-plastic package material how much money a square

- The common aluminum thickness on the market is 0.21 mm, 0.30 mm, 0.40 and 0.50 mm, then the price is in the range of 90-180 yuan / square meter.

- Q: Custom aluminum-plastic plate head signs how much money 1 square meter? How to count

- There are two common practices, one is the paste, one is the problem to add the dry hanging. Among them is the use of fire plywood to do the substrate, and then brush the surface of the plywood to the aluminum-plastic plate Open the finished material, the paste construction and dry hanging method is to triangular iron metal keel welding is completed, flat and vertical, the aluminum plate material buckle in the keel above the use of core pulling rivets fixed, if left You can fill the sealant, etc. Two kinds of materials used in different materials, accessories and accessories are different, so there will be differences in the offer, the general door of the contractor package material prices in 200 yuan, Suitable for the paste process thickness of 3 mm, suitable for dry hanging process thickness of 4 mm, the price difference is greater.

Send your message to us

Golden mirror acp / TOBOND aluminum composite panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords