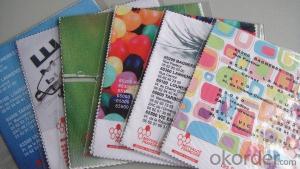

Glasses cleaning cloth with custom heat and hot transfer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of glasses cleaning colth

1.glasses cleaning cloth,microfiber glasses cleaning

2.any size /color is available

3.customized logo

4.polyester&polymide

We manufacture all kinds of microfiber to cleaning cloth,eyeglasses pouch ,polishing cloth ,jewellery bag and so on.

We can customize any product according to your requirements, any size, color, package, qualities, printing is available.

Specialized and experienced, we have engaged in making microfiber products for over 10 years.

Over 5 quality inspectors each department, we have great control on quality aiming at offering you the best goods.

Material 80%polyester+20polyamide / 100%polyester

Size 5*3,5*7,6*8,8*10etc (any size is available)

Printing Digital print, silk print, etc (can print customer logo with Pantone colour)

Colour White, black, orange, yellow, grey, blue, green. Etc (can dye cloth with Pantone colour)

Edge Saw edge, round edge, straight edge, cut cloth into egg shape, etc

Gram weight:(gms)t 180-230gsm

Package 1. 100 pcs each in a polybag 2. each in a polybag 3. individual pvc(vinyl) pouch

MOQ 3,000 pcs (available colors in stock), 20,000 pcs (customized color)

Imprint Silkscreen,digital printing(heat tranfer ptinting),hot stamp,embroidery

Packing

1.bulk packing:100pcs per opp bag 2. individual packing: each in a opp/vinlye bag

- Q: The difference between superfine fiber PU synthetic leather and traditional synthetic leather

- Microfiber synthetic leather consists of two parts, polyamide fiber and polyurethane. They are closely joined together. In the fabric structure, superfine fibers are cross-linked together to form a skeleton and supporting structure, forming structures similar to those of dermal collagen fibers. Distributed around the fiber is polyurethane, which makes the entire synthetic leather fabric as a whole, and has many functions. It is not a simple filling in leather, but has many round, needle like foaming structure, and the whole is solid mesh. The structure of the hair groove is interlaced to form a micro transparent structure, so that the leather body has certain permeability and moisture permeability.

- Q: Polyester fiber is not environmentally friendly fabrics?

- Polyester fibers are: light, ventilation, heat insulation, anti ultraviolet, fireproof, moisture-proof, easy cleaning, anti tearing, not easy to deform, compared with other materials, it has the effect of energy saving and environmental protection.

- Q: Is carbon fiber a composite?

- Carbon fiber is an inorganic high polymer fiber with carbon content higher than 90%. Which contains more than 99% carbon fiber called graphite fiber. The microstructure of carbon fiber is similar to that of synthetic graphite, and it is disordered graphite structure. The spacing between the layers of carbon fiber is about 3.39 to 3.42A, and the carbon atoms in the parallel layers are arranged not as neatly as graphite, and they are connected by the van Edward force between the layers.

- Q: Identification of carbon fiber frames

- Carbon fiber frames are mainly made of carbon fibers reinforced with metal or resin wrapped outside. I've seen this before. Some bikes and tennis rackets use carbon fiber reinforced ones that are lighter, but have greater resistance to bending and shearing.

- Q: Why does pure cotton fabric fall off?

- Easy to cause skin diseases, respiratory diseases, etc.. The textile products are used for physical hair removal. It is not like the same chemical hair removal clean floating hair, there will be some stubborn floating hair can not be cleaned, but this does not affect the use.

- Q: What are man-made fibers? What are his strengths and weaknesses?

- The new representatives of man-made fibers are new fabrics, such as light burned mercerized cotton, silk, Khmer and so on. These materials are soft, comfortable, and do not shrink, and they are highly flexible and extremely smooth. Although it has become the designer's preferred fabric, but the disadvantage is that its price is not as good as nylon, but can not be fully promoted.

- Q: The difference between polyvinyl alcohol and polypropylene fiber

- Polypropylene fibers made of polypropylene and a variety of organic and inorganic materials, the composite refining technology of special form, can improve the fracture toughness of concrete, improve the anti cracking performance of concrete, mortar and concrete engineering is cracking, seepage, wear resistance, thermal insulation material of the ideal model.

- Q: Nitrocellulose (collodium) toxic?

- Cotton, viscose, cotton, fire fire Collodion nitrocellulose solution, for trauma, injury, because of the dry shrink film, hemostasis, promote wound healing and protection.

- Q: Comparison of bamboo fiber reinforced flooring with wood fiber reinforced flooring

- Laminate flooring commonly known as "Diamond Board", the standard name for "impregnated paper laminated wooden floor."". Laminate flooring is generally composed of four layers of material, namely, wear-resistant layer, decorative layer, high-density base material layer, balance (moisture-proof) layer. The qualified laminate flooring is made of one or more layers of impregnating thermosetting amino resins. It is covered with high density board and other base material. The back is balanced with damp proof layer, and the front is added with decorative layer and wear-resisting layer.

- Q: Will the material be 100% polyester fabric?

- Polyester fiber is a chemical synthetic material. It is available in many clothing materials nowadays. It is combined with cotton components in most clothing

Send your message to us

Glasses cleaning cloth with custom heat and hot transfer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords