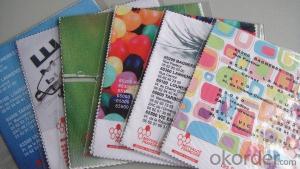

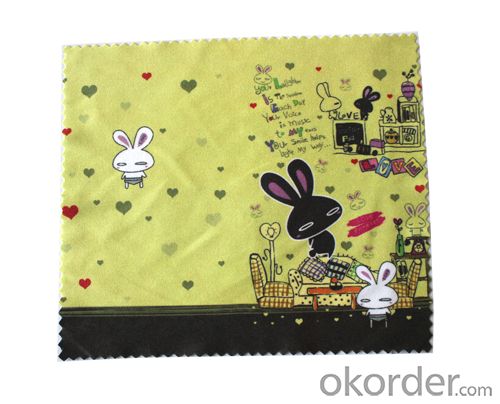

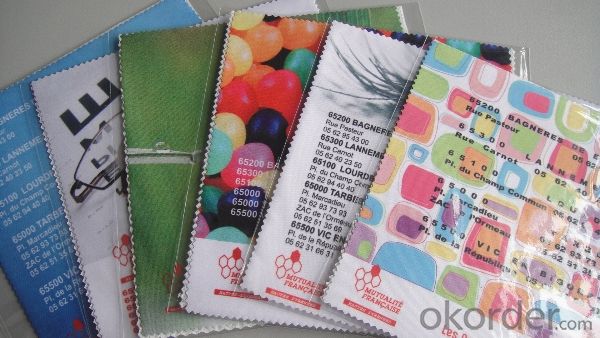

Glasses cleaning cloth with digital printing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of glasses cleaning colth

1.glasses cleaning cloth,microfiber glasses cleaning

2.any size /color is available

3.customized logo

4.polyester&polymide

We manufacture all kinds of microfiber to cleaning cloth,eyeglasses pouch ,polishing cloth ,jewellery bag and so on.

We can customize any product according to your requirements, any size, color, package, qualities, printing is available.

Specialized and experienced, we have engaged in making microfiber products for over 10 years.

Over 5 quality inspectors each department, we have great control on quality aiming at offering you the best goods.

Material 80%polyester+20polyamide / 100%polyester

Size 5*3,5*7,6*8,8*10etc (any size is available)

Printing Digital print, silk print, etc (can print customer logo with Pantone colour)

Colour White, black, orange, yellow, grey, blue, green. Etc (can dye cloth with Pantone colour)

Edge Saw edge, round edge, straight edge, cut cloth into egg shape, etc

Gram weight:(gms)t 180-230gsm

Package 1. 100 pcs each in a polybag 2. each in a polybag 3. individual pvc(vinyl) pouch

MOQ 3,000 pcs (available colors in stock), 20,000 pcs (customized color)

Imprint Silkscreen,digital printing(heat tranfer ptinting),hot stamp,embroidery

Packing

1.bulk packing:100pcs per opp bag 2. individual packing: each in a opp/vinlye bag

- Q: What are the basic features of polyester fiber?

- Good elasticity. The elasticity close to wool, when stretched 5% ~ 6%, can almost completely recover. Wrinkle resistance over other fibers, that is, fabric does not wrinkle, good dimensional stability. The modulus of elasticity is 22 to 141cN/dtex, 2~3 times higher than that of nylon. . the strength and elasticity of polyester fabric has high resilience, therefore, the color fastness and durability, anti crease.

- Q: What's the difference between chemical fiber goods and pure cotton?

- Clothing is made of fabric, which is the material used to make clothes. As one of the three elements of clothing, fabric can not only interpret the style and characteristics of clothing, but also directly influence the color and shape of clothing.In the big world of clothing, the fabrics of clothing are multifarious and changing with each passing day. But generally speaking, high quality, high-grade fabrics, mostly has the characteristics of wearing comfortable, sweat absorbent breathable, drape neat, elegant, soft tactile vision etc..The dress in formal social occasions should choose clothing, cotton, wool, silk, pure pure hemp products. Most of the garments made of these four kinds of pure natural fabric are of higher quality. Sometimes, clothing made of pure leather is also permissible.

- Q: Is the shirt pure cotton or cotton mixed with polyester?

- Cotton and polyester blended shirt, indeed more crisp, easier to manage, but not easy to wrinkle, but personal comfort will be greatly inferior to cotton clothes. Especially for you, polyester fiber (polyester) is higher in content than cotton. If your skin is more sensitive, but it is next to wear a shirt (do not wear bottoming), it is recommended to buy cotton well.

- Q: Bamboo fiber fabric is a back - it regenerated fiber

- Not the same. Recycled fibers include bamboo fibers, and bamboo fiber is one of the fibers.

- Q: Can the mask made of high electrostatic fiber be washable?

- Can not.Commonly used dust masks on the market, the filter materials are melt blown non-woven fabrics, materials are mostly polypropylene, commonly known as PP melt blown cloth, is a superfine electrostatic fiber cloth, dust can be captured, medical teaching

- Q: What fabric is polyester fiber?

- Has the advantages of strong wear resistance, a crisp sense, easy washing, easy to dry, color fastness is good, do not fade not shrink. 80s is the popular Dacron blended polyester fabric. Not afraid of disadvantage, Mars, air permeability, water will become transparent, fabric friction parts will be the light, poor thermal performance etc..

- Q: Is Chiffon the same as polyester?

- If prices are concerned, polyester Chiffon should be cheaper. The fruiting of polyesters. I hope I can help you.

- Q: What's the difference between a silver fiber radiation suit and a metal fiber radiation suit?

- In the end, anti radiation clothing which kind of material is good, we look at the current market anti radiation clothing mainstream fabric:1: metal fiber blended fabric. Generally use a diameter of about 0.008 millimeters of stainless steel, metal fiber and cotton and polyester fiber blended into fabrics, good fabric shielding value of more than 30DB. It has better flexibility because of the addition of other fabrics. Parameters: breathable, washable, shielding, stable performance;2: all silver fiber knitted fabric. The silver fiber here is not pure silver, but a new composite fiber made of silver ions and ordinary fabric. In addition to having good breathability, it also has the function of bacteriostasis and maintenance to human body. The shielding value of all knitted fabric with silver fiber is above 70DB. This fabric is easy to oxidize, but oxidation does not affect the effect of radiation protection and the use of clothing. Parameters: breathable, washable, antibacterial, maintenance, elimination of static electricity, shielding performance is stable;3: semi silver fiber blend fabric. Silver fiber fabric refers to made of silver fiber and polyester fiber blended fabric, the fabric shielding value between metal fiber and the silver fiber fabric, usually around 50-60DB, antioxidant capacity than the silver fiber fabric, but also has a role in the maintenance of antibacterial. Parameters: breathable, washable, antibacterial, maintenance, elimination of static electricity, shielding performance is stable;

- Q: Which is good, hemp or bamboo fiber?

- Hemp and bamboo fiber fabrics are relatively cool, but Ma feel hard, after washing fluid; bamboo fiber smooth, natural antibacterial, known as breathing fiber, absorb sweat, do not stick to the skin, the overall comparison, bamboo fiber as a new type of fabric is better than ma. But the price is relatively higher.

- Q: What's the difference between high density fiberboard, oak and fir?

- Oak, pine, fir wood is relatively scarce, in general, if the oak is solid, then it is oak finger board or fir finger board, the cabinet is more environmentally friendly, but also through some process can be used to make the cabinet.

Send your message to us

Glasses cleaning cloth with digital printing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords