Glass Wool Mineral Wool for Roofing and Partition Wall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Wool Blanket For Insulation

INTRODUCTION

In the field of insulation materials, weare mainly specializing in Glass wool products, including blankets, boards andpipes. The advantage of this material is numerous: noncombustible, nontoxic,and resistant to corrosion. It has low weight, low thermal conductivity, stablechemical property, low moisture rate and good hydrophobicity. These productshave been widely used in heat preservation, thermal insulation and soundabsorption in construction, chemical industry, electronic industry, electricpower, metallurgy, energy industry, and communication. High density panelslaminated with facing can be used for Air-conditioning duct system.

The Kinds of Glass Wool Insulation

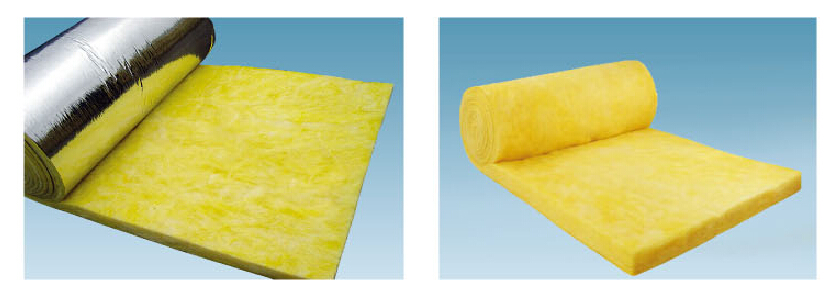

* glass wool blanket plain or with Aluminum foil -clad(Kraft paper or white PVC/WPSK)

* glass wool board

* glass wool pipe

Our Advantage

* Short delivery time

* Origin of China, FROM A / E/ F

* Stable good quality with competitive price (CE certificate)

TECHNICAL DATA

Item | Unit | Index |

Density | Kg/m3 | 10-100 |

Average Fiber Diameter | μm | 5-7 |

Water Content | % | ≤1 |

Grade of Combustibility | Non-Combustible Grade A | |

Reshrinking Temp | ℃ | ≥250 |

Thermal Conductibility | w/m.k | 0.038-0.06 |

Hydrophobic | % | ≥98 |

Moisture Rate | % | ≤5 |

Noise Resistant Coefficient (NRC) | 0.75 | |

Slag Inclusion Content | % | ≤0.3 |

CE CERTIFICATE

Glasswool Blanket

Introduction

The glass wool blanket is applied for largelaying area. Besides the character of thermal insurance, it also has theperformances of shock absorption and acoustical isolation, especially for middleor low frequency sound. It also can cancel the noise and improve workingenvironment.

The glass wool blanket with aluminum foilsurface has good capability of heat radiation protection.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 10-32 |

Thickness | mm | 25-150 |

Width | mm | 600-1200 |

Length | mm | 10000-30000 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

This material can be freely cut inconstruction according to the shape required, mainly used in room,noise-canceling system, transportation, refrigerators and household electricappliances for noise canceling.

The blanket with aluminum foil is suitablefor high temperature shops, control room, inner wall of the machine shops, roomseparating and inner liners.

Package

Normal packing: Each roll is wrapped withvacuum plastic bag, and then in PE woven bag.

Special required package like PE BAG and PESHRINKED BAG can be made with additional charge.

Glasswool Pipes

Introduction

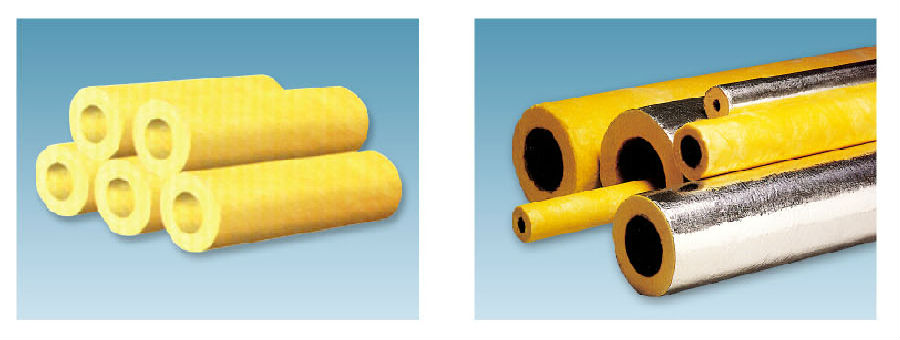

As this material has the characters ofwater-proof, anti-corrosion and mildewing-proof, glass wool pipe is good atstopping condensation and freezing of the pipes.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 48-96 |

Thickness | mm | 25-90 |

Diameter | mm | 18mm-529mm(3/4 inch to 21 inch) |

Length | mm | 1 000,1 200 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

It is widely used in building, heating powerpipes, air conditioning and refrigerators for thermal insurance, such as hotwater pipes, steam pipes, electric power, petroleum and chemical industries.

Glass wool pipe faced with Alum Foil can beapplied to the surface for preventing moisture and radiation.

Package

Reasonable pieces will be packed withplastic bags or carton box, and then into container.

Glasswool Boards

Introduction

Glasswool board is a kind of plate productwith fixed strength after hot-setting of the centrifugal glass wool. It hasexcellent thermal insurance performance in the environment of both high and lowtemperature.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 24-96 |

Thickness | mm | 20-100 |

Width | mm | 600-1 200 |

Length | mm | 1 200,2 400 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

Application

It is mainly used for the partition wall inthe high-grade building, such as ceiling, air conduit and inner wall forthermal insurance, machine shops for noise absorption, and metal ceiling forcontrol of moisture.

High density panels with laminated facingcan be used for Air-Conditioning Duct System.

Package

Reasonable pieces will be packed withplastic bags, and then into container.

- Q: Could centrifugal glass wool be treated as cold insulation material?

- yes, central air conditioning is useful.

- Q: Centrifugal glass wool board and polyurethane foam, which has better thermal insulation performance?

- Polyurethane foam is better, it depends.

- Q: Does glass wool belong to the asbestos insulation material?

- Asbestos products have many varieties and they are mainly used for thermal insulation in industrial equipment and industrial pipes. The operating temperature is within 600 ℃. Compared with glass wool, asbestos products also have more forms. They include asbestos cloth, rope, tape, sheet, blanket, packing (sealing materials), quilt (for fire suppression) and paper.Glass wool is mainly used for thermal insulation of buildings and air ducts. The operating temperature is within 450 ℃.The main products areglass wool plates and carpets.It need to be noted that asbestos is non-environmentally friendly materials and it is radioactive. Long-term contact with it may do great harm to the human body, thus the production of it is banned.

- Q: What are the differences between glass asbestos and glass?reinforced?plastics?

- Asbestos is the general term of natural fibrous silicious minerals, which is a silicate mineral fiber fireproof?panels of construction materials. It is the only natural mineral?fiber with good tensile strength, thermal insulation and corrosion resistance performance, thus it has a wide application. There are many kinds of asbestos, the three most common ones are chrysotile asbestos(white asbestos), amosite asbestos(brown asbestos) and crocidolite asbestos (blue asbestos), and the chrysotile asbestos is the most abundant, and commonly-used one. Glass fiber is an excellent inorganic nonmetallic material. The original name in English: glass fiber. Glass balls or discarded glass are raw materials of it. And it is rocessed by techniques of high temperature melting, wire drawing, winding, and weaving. Finally, it becomes various products. The diameter of glass fiber's monofilament is from a few microns to twenty microns which equals to the 1 / 20 to 1 / 5 of human hair. Each bundle of fiber precursors is composed of hundreds of or even thousands of monofilaments. Usually, it is used as reinforced materials,electric insulation materials, thermal insulations and circuit boards in complex materials, and is widely used in various fields of national economy. Glass fibers are twistless roving and textile gauze with different specifications and uses which are twisted. There are two kinds, namely alkali-free (R2O<0.8%, Code E) and alkali (R2O12.0±0.47%, Code C). They are mainly used as reinforcing materials for hand lay-up, lamination, winding and spraying formation of glass?reinforced?plastics, as well as are contributors to the production of electronic insulation, composite, and fireproofing glass?fiber products.

- Q: Does anyone know about the filling materials in the steel stud, is it glass wool or mineral wool?

- Relatively glass wool of famous brand is more environmentally friendly. Rock wool has larger particles. They all have good thermal insulation and sound absorption performance, but are not recommended to use them both. The proportion of glass wool used is smaller than that of rock wool in terms of the same sound absorption performance. It may contains asbestos.

- Q: Is the microporous aluminum silicate coated with aluminum wool?

- Is the microporous aluminum silicate coated with aluminum wool?

- Q: What is the difference between anti-high temperature glass wool and ordinary glass wool?

- Difference: High-temperature glass wool is made up of glass fibers and special high-temperature adhesive. It is yellowish with curing agent as the high temperature adhesive and with a small quantity of glue. While ordinary glass wool is dark yellow with ordinary resin adhesive as the binder.

- Q: how to choose external wall insulation materials for glass wool?

- Extrusion plate: Better physical property, small heat-transfer coefficient, low cost, suitable for buildings that requires not much exterior decoration; phenolic foam board: it can reach A level fireproof, low heat transfer coefficient, high cost. it becomes powders after hand pinching. It has poor adhesion; modified polyurethane board: It can reach A level fireproofing, low heat transfer coefficient, high cost. It can be used with various decorative materials.

- Q: The differences between rock wool board and glass?wool?board

- good explanation

- Q: What is the difference between high density glass wool board and stereoplasm rock wool board?

- Centrifugal glass wool uses glass as the main raw material. Glass mixed with a certain percentage of other materials should be fully melted in the glass furnace. The melted solution will flow out of bushing and enter into the centrifuge.In the high speed centrifuge, glass will be thrown into a glass thin stream. Under the effect of high temperature and high speed flame, glass thin stream is further stretched into fibers and sprayed with foggy adhesive. In the effect of negative pressure wind cotton webs, the fibre with resin adhesives falls on mesh belt, forming a homogeneous cotton blanket and then it is solidified in thermostat curing oven. After the shape of it is fixed, the glass wool will become predetermined products after cut and then be packed.The main raw material of rock wool products is fine basalt rock. The basalt rock is made into inorganic fiber after meited under high temperature and processed in the high-speed centrifugal device. Then the arrangement structure of the fibre is changed after it is add with special binder and dust laying oil and put in a special device. In the last step, the product is solidified and become a new lightweight thermal insulation material. Depending on the application, it can be processed into wool board, rock wool blanket and wool shell.Compared with rock wool, glass wool is of lower unit weight, less shot content, lower thermal conductivity, long service life and high tenacity fiber, rock wool. However, the maximum operating temperature of rock wool is about 600 degrees Celsius while the glass wool is only about 260 degrees Celsius.Glass woolwool is generally used in thermal insulation part less than 200 degrees Celsius and is mainly used for thermal insulation in general buildings or low temperature pipes. Rock wool is generally used at thermal insulation part with the temperature of 500 degrees Celsius and is mainly used for heat perservation of of high temperature heat pipes or electrical equipment.

Send your message to us

Glass Wool Mineral Wool for Roofing and Partition Wall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords