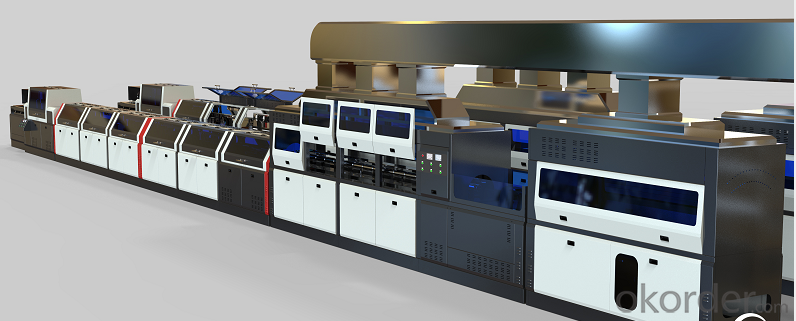

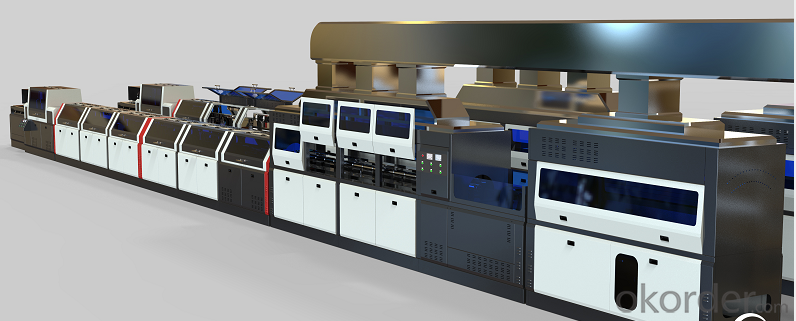

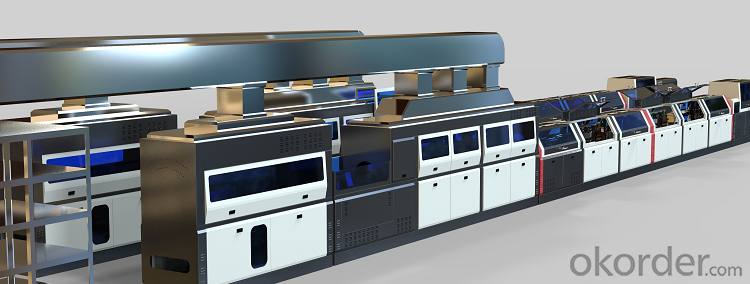

Glass reinforced plastic anchor rod production equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

My company research and development, production and sales have all threaded glass reinforced plastic anchor rod production line of the world's leading standard.

The length of the line at home and abroad and its own unique technology, has many characteristics, such as advanced technology, reliable performance.

This production line is mainly advantages: high efficiency (1000-1500 - mm/min, are two to three times of general equipment); To save the cost of materials (10-30%) can decrease; Cost saving process (1-3 yuan/m); High automation easy operation (4) / 2 production line; Environmentally friendly low energy consumption.

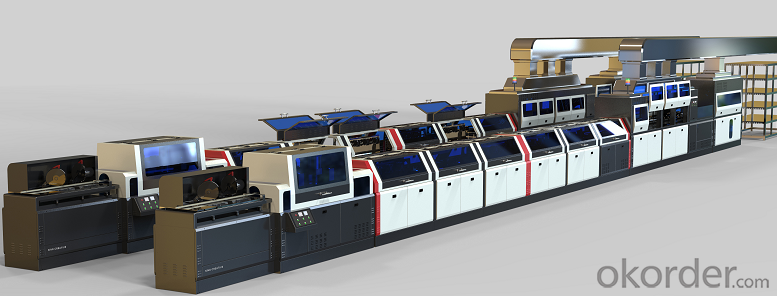

Company can match for different clients, all kinds of nuts and tray processing equipment (including high strength non-metallic nut, the bearing capacity of the pallet 150 kn) or higher.

Company can also offer to the customer required to produce a series of special resin, curing agent and other raw materials, price is superior.

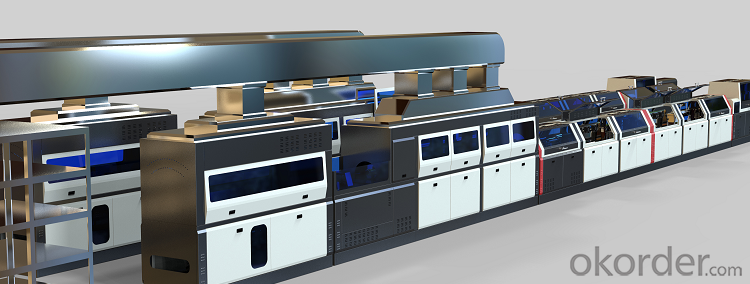

Glass rod equipment and product advantages:

A, a molding: pole, mother

Second, the speed: 1.2 meters per minute

Three, large torque, more than 50-130 according to customer's need

Four, carrying big: tray, the self-contained mother is our patent products

Five long, continuous production time: 36 hours

Six, low cost, lower 1-2 yuan per meter

Seven, provide raw materials: sell cheap

Eight, formulation science, reasonable of tesco

Nine, life-long service: repair and simple

10, a variety of cooperation: a win-win purpose * thick jersey cargo

To make science and technology into productivity, to make glass reinforced plastic anchor rod in coal, building and other fields used widely as soon as possible: sincerely welcome industry peers to company guidance, hit new high together!

Sincerely welcome clients to visit our company guidance, win-win premise to seek common development!

- Q: What is the chemical equipment

- 1) chemical machine. Refers to the main parts for the movement of the machine, such as all kinds of filter machine, crusher, centrifugal separator, rotary kiln, mixer, rotary drier and fluid conveying machinery, etc. (2) chemical equipment. Refers to the main function parts is stationary or only a small movement of the machine, such as all kinds of containers (tank, pot, kettle, etc.), ordinary kiln, a column, reactor, heat exchanger, the common dryer, evaporator, reactor, electrolytic cell, crystallization equipment, mass transfer and adsorption equipment, fluidization, ordinary separation equipment and ion exchange equipment

- Q: Why is the volume of the chemical plant bulky

- One, large capacity has capacity; The necessary conditions for the chemical reaction. A chemical plant, as the name suggests, is a factory that reacts chemically to produce goods. Chemical reactions, you know, chemical reactions, if you don't have to heat it up, you're going to get a lot of heat out of it. Produce high temperature and high pressure gas or product. To get qualified in the case of a controlled product, chemical reactions must be provided the required conditions, the reaction kettle is enough big, can provide enough quantity, and fully contact materials. At the same time, there is also a circulating water device to cool down or heat the steam. In addition, the output of the chemical reaction (often multiple, the main produce and the secondary output), also has to be large enough to be dressed up. So, smaller chemical plants, and there are a few essential devices, and they're going to be very large.

- Q: In a chemical industry, the electrician's department is cutting away from where it is made. Is that ok

- Explosion accident prone to chemical enterprises in the production of raw materials and products are flammable and explosive, the characteristic of high temperature and high pressure, prone to leakage of chemical dangerous goods when maintenance or remaining in the equipment lines, in the commissioning phase may be remaining in the equipment or mixed with air, form an explosive mixture gas, once fires raging fires often and severe losses.

- Q: Which equipment should be classified into the main equipment in chemical production?

- The main equipment is mainly used for production and storage. For example, the compressor, refrigerator, generator, pump, etc. Can only be auxiliary equipment. There is no definite definition of this

- Q: Production equipment and system sealing operation in chemical production

- Statistics from some developed countries show that chemical companies accounted for a third of the explosion in industrial enterprises. In addition, in chemical production, it is inevitable to contact poisonous and harmful chemicals, and the incidence of occupational disease in the chemical industry is significantly higher than that of other industries.

- Q: Is the management of chemical plants harmful to the body

- Chemical equipment management is mainly faced with the following tasks: Technical standard validation of equipment procurement Equipment installation debugging and integrity verification 3, preventive maintenance/maintenance Fail-equipment repair Plan internal maintenance (commonly known as "overhaul") Spare parts management Legal special equipment management

- Q: There are chemical products for machining

- Mechanical processing is a process of changing the shape or performance of the workpiece by machining machine. The temperature state of the workpiece is divided into cold processing and hot processing. It is usually processed at room temperature and does not cause chemical or material change in the workpiece, which is called cold machining. In the case of a process that is above or below normal temperature, the chemical or object of the workpiece is changed, which is called hot machining. The difference in processing mode can be divided into machining and pressure processing. Hot processing is common in heat treatment, calcining, casting and welding. Various kinds of equipment, general term: heat treatment equipment, forging equipment, casting equipment, welding equipment, metal cutting machine, press, etc. The big categories of metal cutting machine tools are: car, drill, boring, grinding, gear processing, milling, plane, pull, special machine tool, etc.

- Q: The overall requirements of the products for the fans are higher

- This is too much. You can say that. Basically all the chemical companies need the fan and the food factory needs it.

- Q: What can be used for titanium or titanium alloy materials in the chemical industry?

- Titanium in the dosage of chemicals used in the earliest, the largest is the chlor-alkali industry, at present the national medium chloralkali plant nearly 200, most of them adopt titanium anode tank and ionic membrane electrolyzer caustic soda production, so the titanium equipment with bigger quantity. Soda ash also called sodium carbonate, is one of basic chemical raw materials. The method of soda ash production mainly include natural soda and salt as raw materials of the ammonia soda and soda. Whether in the process, equipment is strong corrosion media such as sodium chloride and ammonium chloride. Foreign equipment of titanium in the soda ash industry has been widely used, China since 1965, dalian chlor-alkali industry research institute, Shanghai pudong chemical fertilizer plant, alkali factory russsian company, tianjin factory, hon crane chemical plant, hubei chemical plant, alkali factory in Qingdao, and all three factory has used the new titanium, titanium equipment. Chemical industry in the inorganic chemicals, inorganic compounds, organic chemicals and chemical fertilizers, pesticides, dyes, fine chemical, chemical reagent and titanium are also widely used.

- Q: What is the production and attention of water treatment in chemical industry?

- Ultrapure water is the state environmental protection requirements which conform to the national first class or second class discharge standard of water, water purifier used in the process of water treatment poly aluminium or polyacrylamide remember not to pay attention to the usage form secondary pollution

Send your message to us

Glass reinforced plastic anchor rod production equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords