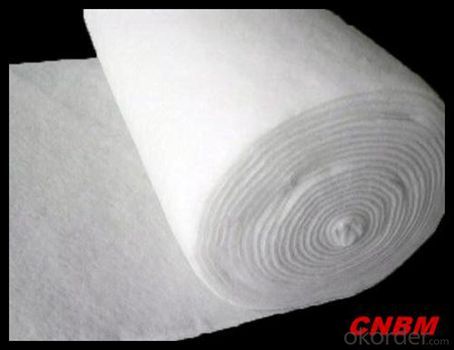

Geotextile Felt Fabric for Filament Woven Geotextile in Dykes and Dams Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Introduction:

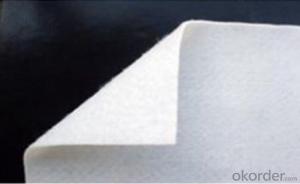

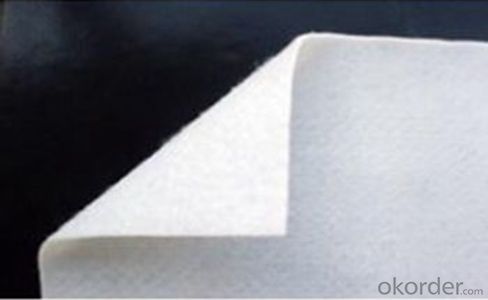

Description: High strength industrial synthetic fiber as the raw material, made through weaving technology.

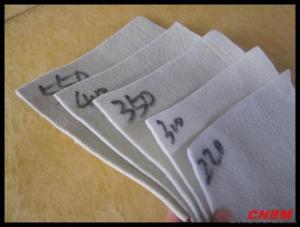

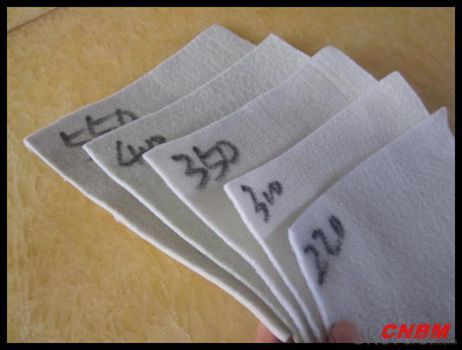

Specification:

Nominal breaking strength in MD (kN/m): 35, 50, 65, 80, 100, 120, 140, 160, 180, 200, 250, width within 6m.

Property:

1. High strength, low deformation

2. Durability: steady property, not easy to resolved, air slaked and can keep the original property long term.

3. Anti-erosion: anti-acid, anti-alkali, resists insects and mould.

4. Permeability: could control the sieve size to retain certain permeability.

Application:

It is widely used in river, coast, harbor, highway, railway, wharf, tunnel, bridge and other geotechnical engineering. It could meet all kinds of geotechnical projects needs such as filtration, separation, reinforcement, protection and so on.

Functions

1.Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different

granule pathway from the groundsill or other buildings.

2.Reinforcement

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earthbody stability.

3.ProtectionIt prevents the bank from being washed out, protects the bank and the

bottom, prevents the water and soil from being washed away

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the considerations for geotextile selection in road rehabilitation projects?

- When selecting geotextiles for road rehabilitation projects, several factors need to be considered. These include the type and severity of the road distress, the traffic volume and load requirements, the soil conditions, and any environmental concerns. Additionally, the geotextile's strength, durability, and compatibility with other materials used in the road rehabilitation process should also be taken into account. Proper consideration of these factors ensures that the selected geotextile will effectively enhance the road's performance and longevity.

- Q: The difference between the construction hdpe impermeable membrane and the geotextile

- Hello, this is two different products Geotextile is not seepage, but the role of filtered water HDPE geomembrane is waterproof. Huazhi geotechnical materials manufacturers to answer your questions

- Q: What are the installation guidelines for geotextiles used in erosion control blankets?

- The installation guidelines for geotextiles used in erosion control blankets typically involve the following steps: 1. Site preparation: Ensure that the area where the erosion control blanket will be installed is properly graded and free of any debris or vegetation. 2. Unroll the geotextile: Start by unrolling the geotextile fabric along the slope or area where erosion control is needed. Make sure to overlap the fabric by the specified amount to ensure complete coverage. 3. Secure the fabric: Use stakes or landscape pins to secure the geotextile to the ground, especially at the edges and corners. This will prevent it from shifting or being displaced during installation or heavy rainfall. 4. Seam connection: If multiple rolls of geotextile fabric are required, ensure that they are properly overlapped and securely connected using a recommended seam connection method. This will ensure a continuous and seamless coverage. 5. Anchoring: In certain cases, additional anchoring may be required to provide extra stability. This can include using sandbags, rocks, or other suitable materials along the edges or across the surface of the geotextile fabric. 6. Vegetative cover: If the erosion control blanket is designed to support vegetation growth, follow the recommended guidelines for seed or plant installation. This may involve spreading seeds or planting live vegetation through the geotextile fabric. It is important to note that these guidelines may vary depending on the specific erosion control blanket and geotextile manufacturer, as well as the site and project requirements. It is always recommended to refer to the manufacturer's installation instructions and consult with a professional engineer or erosion control specialist for proper installation and best results.

- Q: What is the consequence of the geotextile of the ground floor

- What are the consequences of what can not be finalized, the first roof of the waterproof layer and waterproof protective layer is very important, this is the first barrier, imagine, now many of the green plants are large trees, grow 10 years or even 20 years After the roots will be very developed, think about how the pine trees on the tenacious know their strength, coupled with long-term erosion by the water, the concrete layer will gradually lose its ideal performance, barrier layer and drainage board will certainly be better To protect the role and drainage. So to speak, long-term vision of the words must be solidly do every layer, only focus on economic interests and short-term effects, then, within a few years will not be any problem.

- Q: How do geotextiles help in subsurface drainage?

- Geotextiles help in subsurface drainage by providing a permeable layer that allows water to flow through while preventing soil particles from clogging the drainage system. This helps to improve the efficiency of the drainage process, prevent soil erosion, and maintain the stability of the subsurface.

- Q: what is the life span of a geotextile tube ?

- Engineered geotextiles have design lives of up to 120yrs. It depends on what geotextile you are talking about and what environment it is placed in.

- Q: What are the factors to consider when specifying geotextiles?

- When specifying geotextiles, several factors need to be considered. These include the specific application and function of the geotextile, the required strength and durability, the type of soil and environmental conditions, the installation method, and any relevant regulatory requirements or standards.

- Q: Geotextile general what materials are produced

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or woven from the permeability of geosynthetics. Geotextile is a new material geosynthetics which one, the finished product for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a spinning geotextile and non-woven filament geotextile. Geotextile manufacturers, for your answer

- Q: Why is the roadbed geotextile

- Put the geotextile for water treatment

- Q: Are geotextiles suitable for use in coastal erosion control?

- Yes, geotextiles are suitable for use in coastal erosion control. They can effectively stabilize soil, prevent erosion, and promote vegetation growth in coastal areas. Geotextiles provide a barrier against wave action and help to retain sediment, reducing the rate of erosion and protecting shorelines from further degradation.

Send your message to us

Geotextile Felt Fabric for Filament Woven Geotextile in Dykes and Dams Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords