GATE VALVE RISING STEM WEDGE DUCTILE IRON DN40-DN600

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard or Nonstandard: | Standard | Structure: | Gate | Pressure: | Medium Pressure |

Power: | Manual | Material: | Casting | Temperature of Media: | Normal Temperature |

Media: | Water | Port Size: | DN50 | Place of Origin: | Tianjin China (Mainland) |

Brand Name: | CMAX | Nominal diameter:: | DN40-DN600 | Working pressure:: | 10bar/16bar |

Valve Design:: | DIN3352 | Face-to-face:: | DIN 3202-F4/F5 | Flange accommodation:: | EN1092-2 PN10/16 |

Test Standard:: | ISO 5208 |

Packaging & Delivery

Packaging Details: | plywood case |

Delivery Detail: | 30 days |

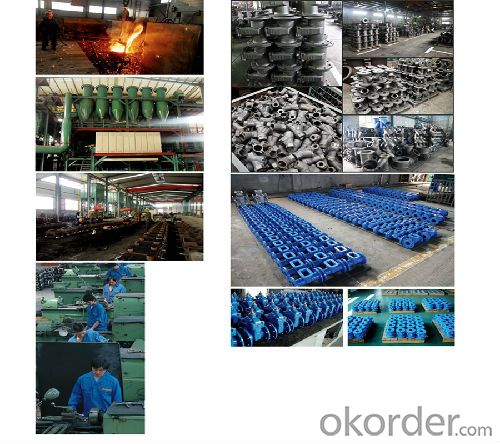

Introduction

Rising Stem Wedge Single Disc Gate Valve is installed in pipeline as a closing device and can not be used to regulate flow and exhaust to the open.

Parameter

Suitable medium | Steam, Water, Oil |

Suitable temperature | ≤ 350℃ |

Nominal pressure | PN1.0MPa-PN1.6MPa |

Nominal diameter | DN700mm-DN900mm |

Driving type | Gear |

Product Standard | GB, ISO, BS, DIN, ASME, API, AWWA, and other standards according to customer demand |

Face to Face length | GB, ISO, BS, DIN, ASME, API, AWWA, and other standards according to customer demand |

Material

Main material | Cast iron |

Valve stem | Stainless steel |

Sealing ring | Cast copper, Cast iron, Stainless steel |

Packing | Rubber, Asbestos |

1. Product Type

Ball Valve, Butterfly Valve, Gate Valve, Knife Gate Valve, Globe Valve, Check Valve,

Reducing Valve, Safety Valve, Strainer, etc.;

2. Standards

American Standard (API), German standard (DIN), International Standard(ISO),

GB (GB), British standard (BS), Japanese Industrial Standards(JIS), GOST, etc.;

3. Features:

Design - API 608/ API 6D/ BS5351/ ANSI B16.34/ ISO 14313/MSS SP 72

Face to Face & End to End - ASME B16.10/ ISO5752

Ends - Wafer, Flange RF, RTJ, SW, BW,

Fire Safe - API 607/ API 6FA

Test - API 598

Seat - PTFE/ RPTFE/ VITON/ UR/ EPDM/ NBR/ NR/ Graphite/ Metal to Metal

Bore - Full Bore/ Reduced Bore

Fabrication - One Piece/ Two Pieces/ Three Pieces Body

4. Material

ASTM A216 WCB , A351 CF8, CF8M, CF3, CF3M, CF3MN, CN7M

A890 4A, A352 LCB , ASTM A105, A182 F304, F304L, F316, F316L F51,LF2

Parts | Material |

Body&Bonnet | WCB, WC6, LCB, LCC, CF8, CF8M, Ti, Hastello C, 904L |

Disc & Ball | WCB, WC6, LCB, LCC, CF8, CF8M, Ti, Hastello C, 904L |

Hinge | WCB, WC6, LCB, LCC, CF8, CF8M , Ti, Hastello C, 904L |

Seat | A105,F304,F316,PTFE,RTPFE,VITON,NYLON,NBR |

5. Nominal Diameter (Size)

150#~2500# : 1/2"~80" (DN15~DN2000)

6. Nominal Pressure

Class 150---Class 2500 (PN16-PN420)

7. Operating Temperature

-196 °C --- 650 °C;

8. Application

Chemical, Petrochemical, Oil & Gas, Power Plant, General Industry etc.;

9.Certificate :

API 6D, API 6FA, CE, ISO 9001

- Q: Soft sealed gate valve and hard sealing gate valve which good?

- If the caliber, material and pressure levels are the same, the current market price is still soft sealed gate valve, about 20-30%.

- Q: What are the meaning of the cast rigid gate valves z41h-16c?

- According to the provisions of the JB/T 308-2004 valve type programming method:Z== gate valve4== flange connection1== rigid single gateH== sealing surface material: Cr13 stainless steel16== pressure rating: 1.6MPaC== body material: carbon steel

- Q: What is gate well?

- Technical requirement:1: the valve itself can not seep, it must ensure its tightness;2: water supply pipeline during use, pipeline will be pressure from different aspects, which will produce different degrees of jitter or settlement, which requires the connection of water supply pipes and valves in the well to be reliable, able to adapt to a certain degree of jitter and settlement, and to prevent water infiltration into the well chamber in the pipeline valve wells; deep, slightly larger are generally made of cast iron valve (such as the cut-off valve, butterfly valve) iron valves long-term immersion in water, will affect the service life or cause fracture, so the sealing requirements are higher;3: valve shaft, shaft and well body, manhole cover way of connection should be reliable, not because of heavy rain or water seepage water into the well room.4: valve well is buried in the ground, to bear from different directions of different pressure, and different chemical substances corrosion and damage, and requirements of its pressure capacity and acid and alkali corrosion is better.

- Q: Is the gate valve flanged?

- The most commonly used gate valves are threaded connections, flanged connections, and welded connections.Like the outer thread connection, the clamp connection, the card sleeve is seldom used.

- Q: What's the difference between the knife gate valve and the stop valve?

- Standard light valve professionals to answer for you, gate valve refers to the closure of parts (gate) along the central line of the vertical direction of moving valve. The gate valve is mainly used for cutting in the pipeline. The valve is a valve with a very wide, cutting device general caliber DN = 50mm use it, sometimes a small diameter cutting device also use valve, gate valve has the following advantages:Fluid resistance is small.

- Q: What is the wedge type gate valve wedge is what mean

- B. wedge type single gate, it is the whole wedge gate. In the process of opening and closing the sealing surface is prone to scratches, easy to make the temperature change gate wedge live. It is a gate used for normal temperature, medium temperature and various pressures. C. wedge double plate, which is composed of two gates composed of spherical top hinged into wedge-shaped gate. The advantage is that the accuracy of the cover angle is lower; the sealing surface of the gate can be compensated by adding shim at the top of the seal; the temperature changes are not easy to cause the phenomenon of the card master, nor should it be abraded. Because the gate is movably connected and has more parts, it is easy to bond in the viscous medium and affects the sealing. Especially when the upper and lower baffles are corroded all the year round, the flashboard falls off arbitrarily. It is usually used for water, steam and gas pipelines.

- Q: What does valve qz45x - 10q mean?

- Crown valve pressWhat does Q stand for? I'm not sure. It's probably made of ductile iron"Z" means "gate valve"4 represents flange connection5 represents the dark bar (1 represents the Ming pole)X stands for rubber seal and soft seal10q stands for 10 pressure

- Q: What's the meaning of flexible z45x-10q door valve?

- Crown valve pressModel Z45X-10QZ refers to gate valve4 finger flange connection5 refers to the dark bar driveX refers to rubber seals10 refers to 10 kg pressureQ refers to the body material, ductile ironFull bore flange soft sealed gate valve

- Q: What does the gate valve SZ45X-1.0 stand for?

- A modelModel SZ45T-1.0, especially in DN100 ~ DN300 piping, soft sealing gate valve shall be used

- Q: What is an inverted seal gate valve?

- When the inverted sealing gate valve is fully opened, the sealing of the sealing is brought together, and the sealing effect is reduced, and the erosion of the filling to the fluid is reduced, and the service life of the filler is prolonged, and the possibility of leakage is reduced. Generally on the gate valve, stop valve has inverted sealing requirements.

Send your message to us

GATE VALVE RISING STEM WEDGE DUCTILE IRON DN40-DN600

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords