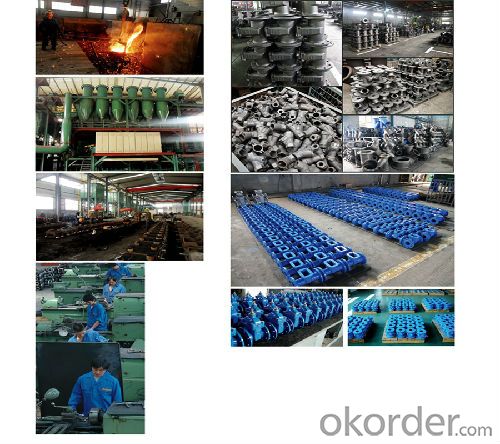

GATE VALVE NON-RISING STEM RESILIENT SOFT SEATED DUCTILE IRON DIN3352 F4 DN40-DN800

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GATE VALVE NON-RISING STEM RESILIENT SOFT SEATED DUCTILE IRON DIN3352 F4 DN40-DN800

Quick Details

Standard or Nonstandard: | Standard | Structure: | Gate | Pressure: | Low Pressure |

Power: | Manual | Material: | Casting | Temperature of Media: | Low Temperature |

Media: | Water | Port Size: | DN40-DN800 | Place of Origin: | China (Mainland) |

Model Number: | Z45X-16 | Brand Name: | CMAX | Coating :: | Fusion Bonded Epoxy Powder Coating |

Disc:: | Flexible disc | market:: | Material:: | Ductile iron |

Packaging & Delivery

Packaging Details: plastic&bubble bags , then wooden box

Delivery Detail: 30days

Specification

| Design and Manufacture Standards | DIN3352 BS5163 ANSI B16.34 API60 API6D and Russian standard |

| Material | Cast Iron (GG20, GG25) Ductile Iron (GGG50) Carbon Steel, WCB Stainless steel |

| Sealing | Rubber Metal |

| Operation | Hand-wheel Driving head Electric actuator |

| Media | Water, Oil etc. |

| Working pressure | 1.0Mpa 1.6Mpa Class150LB-2500 LB |

| Working dimensions | DN50-DN800 |

| Temperature | Normal Temperature |

| Coating | Fusion Bonded Epoxy Powder Coating Akzo Nobel Powder Coatings |

Function and specification :

| Type | Nominal pressure(Mpa) | Testing pressure | Suitable temperature(°c) | Suitable medium | |

| Strength(Water)(Mpa) | Enclose(Water)(Mpa) | ||||

| Z45X-16 | 1.6 | 2.4 | 1.8 | ≤80 | Water |

- Q: What are the specifications of the gate valves? Does the work pressure need to be marked separately?

- According to domestic valve model standards, the valve model is by the valve type, gate valve drive mode, gate valve connection, gate valve structure, sealing material, valve body material code to indicate.1, gate valve type code named Z;2, gate valve drive mode code by letters, common 2- electric hydraulic, 9- electric, 6- pneumatic, 5- bevel gear drive, 3- turbo worm; manual do not need to write out;3, gate valve connection form code with letters to indicate, 1- internal thread, 2- external thread, 4- flange type, 6- welding, 7- pairs clamp type, 9- clamp, 0- card sleeve;4, the valve structure of code, 0- flexible wedge, 1- rod single wedge gate valve, 2- rising stem wedge gate valve, 3- parallel single gate valve, 4- parallel double gate valve,

- Q: Valve flange drawing n- up to what

- A bolt hole used to indicate a flangeThe value of N indicates the number of bolt holesUp to the numerical representation of bolt hole size

- Q: What is gate valve (with force transfer joint)?

- The force transfer joint is mainly used for the loose connection of pumps, valves and other accessories.

- Q: Function of signal butterfly valve and gate valve

- The signal butterfly valve applies to petroleum, chemical, food, medicine, papermaking, water and electricity, ships, water supply and drainage, smelting, energy and other system pipelines. Available in a variety of corrosive, non corrosive gases, liquids, semi fluids, and solid powders.

- Q: What is a protective gate valve? What is gate valve knowledge?

- Door gate, refers to the design of anti blocking nuclear explosion shock wave from the pipe into the project inside the valve, composed of a valve body, valve seat, valve plate and wave absorbing device, wave absorbing device leakage hole in the valve body, valve leakage hole is a cylindrical hole, wave valve has two door sealing groove between the cylindrical hole and wave valve double seal ring seal, between the valve body and the flange is double sealing ring seal.

- Q: What's the difference between open rod gate and dark rod gate valve?

- 4, the dark pole gate valve height smaller size; Ming rod gate valve requires a larger installation space;5, the structure of the rod gate valve is beneficial to the lubrication of the valve stem, and the degree of opening and closing is obvious. The stem thread of the dark rod gate valve is not only unable to lubricate, but also directly accepts the medium erosion and is easy to damage. Therefore, the open bar gate valve is used more widely

- Q: Function of gate valve

- The valve (including the valve and valve) is a fluid pipeline control device, its basic function is to connect or cut off the pipeline medium circulation, changing the medium circulation, change the direction of the flow medium, medium pressure and flow regulation, to protect the normal operation of pipeline equipment.

- Q: Gate valve z11h/y-16 what does that mean?

- Product Name: internal thread gate valveItem number: Z11HProduct specification: DN15-50Product pressure: 1.6MPa-2.5MPaMaterial: cast iron, cast steel, stainless steelInternal thread gate valve nominal pressure 2.5Mpa, applicable temperature range -20-232-350, applicable medium: water, oil, gas and certain corrosive liquid (W.O.G), thread type G.NPT.BSPT.BSP.DIN259/2999.

- Q: Notes on flat gate valves

- internal structureThe 1 seat O ring seal and preload floating seat structure, so that import and export of two-way valve seal plate; and the structure of the normal valve opening and closing torque only 1/2, can easily open and close valves2. when fully open, the channel is smooth and straight, the flow resistance coefficient is extremely small, and there is no pressure loss. The pipeline can be cleaned through the hair bulb3 the packing structure with the ability of self sealing, without frequent adjustment, opening and closing very lightweight, and reliable seal, the stuffing box is arranged at the auxiliary seal oil into the structure, absolutely reliable sealing performance, thereby achieving zero leakage; solve the shortcomings of the general valve packing leakage of the most vulnerable4., when the flat gate valve is closed, it can automatically unload the inner cavity high pressure, and ensure the safe use5., fully enclosed structure, good protection performance, can adapt to all-weather requirements6., the valve seat sealing structure should be elastic, preload, upper and lower sealing seat at the same time sealed structure. The valve seat and the seal are always face to face sealed.The 7. seat has self-cleaning function and is free of direct airflow during valve opening or closing. The seat shall be made of lubricated, non wearing material.8. valve actuator failure will not affect the other parts of the valve, maintenance and replacement work can be carried out without removing the valve.9. yoke sleeve aluminum bronze yoke sleeve with pin type thrust bearing to minimize operation torque.10. stem - thread length until bracket; dowel and spot welding; stability.11. pressure seal - simple construction, with sectional retaining rings and silver plated low carbon steel gaskets, helps to remove and achieve the best bonnet seal.12. seat ring - welded seat ring is perpendicular to the flow channel and is easy to maintain.

- Q: What are the types and product categories of knife gate valves?

- Types and classification of knife gate valves:PZ73H, PZ73F, PZ73Y manual knife gate valve: manual drive, clamp connections, rod parallel rigid single gate and valve seat sealing surface is made of hard alloy, Teflon or stainless steel body processing, nominal pressure.2PN10~16, the valve body material for carbon steel (PZ73H-10C/16C), stainless steel (PZ73F-10P/16P PZ73Y-10P/16P), with the function of slag gate valve.

Send your message to us

GATE VALVE NON-RISING STEM RESILIENT SOFT SEATED DUCTILE IRON DIN3352 F4 DN40-DN800

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords