China cheaper Gate Valve

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

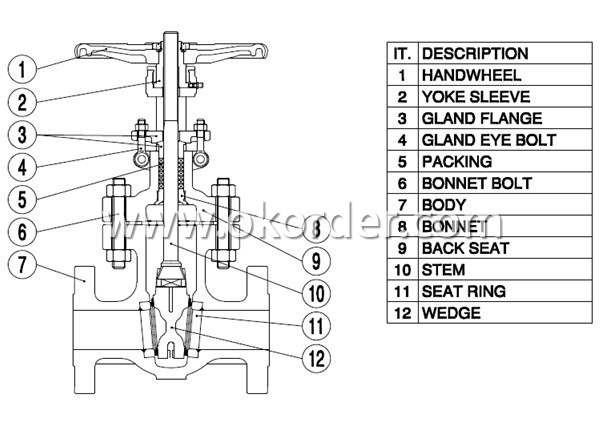

Gate Valve

Flange ends cast steel gate valve are used to cut or connect the pipe media under nominal pressure between class150-2500, working temperature≤600°C, in oil industry, chemical industry, fossil-field power plants.

Design Feature of Gate Valve

1. Both design and manufacture are carry out strictly fellow API600 and API602. The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2. Co hard alloy welded sealing surface, which is wearing resistance, erosion proof, abrasion proof and long-lived.

3. The surface and the adjusting media of the valve shaft are nitrogenized so that it is erosion and abrasion resistance.4. Class≥900LB, the media cavity uses a self-tightening sealing structure to have the sealing performance reinforced along with the pressure rise so as to ensure the sealing performance.

5. There is backward sealing structure in the valve, so the sealing is reliable.

6. The material of the filling and the flange size can be chosen and the matched according to the applications and the requirement of the wier's. That can satisfy all kinds of working requirements.

|

Item |

Material |

Symbol |

|

Body |

Cast Iron |

ASTM A126 CL.B GG25 |

|

Ductile Iron |

ASTM A536 65-45-12 GGG40 | |

|

Carbon steel |

ASTM A216 WCB | |

|

Stainless steel |

ASTM A351 CF8/CF8M | |

|

Disc |

Ductile Iron |

ASTM A536 65-45-12 GGG40 |

|

Carbon steel |

ASTM A216 WCB | |

|

Stainless steel |

ASTM A351CF8/CF8M | |

|

Bronze |

ASTM B148 C954 | |

|

Stem |

Stainless steel |

ASTM A182 304.316.410 |

|

Alloy |

Monel K500 | |

|

Seat |

Elastomer |

Working temperature |

|

EPDM |

-15°C~ 140°C | |

|

NBR |

-10°C ~80°C | |

|

VITON |

-20°C ~150°C | |

|

PTFE |

-15°C~205°C |

The package of gate valves

- Q: Soft sealed gate valve and hard sealing gate valve which good?

- If the caliber, material and pressure levels are the same, the current market price is still soft sealed gate valve, about 20-30%.

- Q: What are the meaning of the cast rigid gate valves z41h-16c?

- According to the provisions of the JB/T 308-2004 valve type programming method:Z== gate valve4== flange connection1== rigid single gateH== sealing surface material: Cr13 stainless steel16== pressure rating: 1.6MPaC== body material: carbon steel

- Q: What are the main types of gate valves?

- According to the thread position of the valve stem, can be divided into two kinds of open rod gate valve and dark rod gate valve.

- Q: Is the gate valve clockwise or closed?

- In general, the valve is clockwise to turn off. Some of the clockwise rotation of the valve on the move is open

- Q: What does gate valve do?

- Like other valves, the gate valve is used to block fluid flow. Is the gate valve opening and closing parts, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle.

- Q: What does the gate valve 150# mean? Is it stress PN? What's that, PN16 or?It's better to have some specific links, thanks!

- 150Lb (American Standard pressure value corresponding to the PN2.0)

- Q: What kind of valve is gate valve? Is it different from the cut-off valve?

- Gate valve and the role of the cut-off valve, are playing a role in isolation. The difference is that the gate valve and the cut-off valve are constructed differently. Fluid from the gate valve flow and flow direction is straight, there is no change in direction, but in the cut-off valve is from the bottom of the valve flow into the flow from the upper part of the spool.

- Q: What do gates, Z15T-10, Z15W-16T, Z45T/W-10, Z41T-10 mean?

- 1, gate valve type code named Z;2, gate valve drive mode code by letters, common 2- electric hydraulic, 9- electric, 6- pneumatic, 5- bevel gear drive, 3- turbo worm; manual do not need to write out;3, gate valve connection form code with letters to indicate, 1- internal thread, 2- external thread, 4- flange type, 6- welding, 7- pairs clamp type, 9- clamp, 0- card sleeve;4, the valve structure of code, 0- flexible wedge, 1- rod single wedge gate valve, 2- rising stem wedge gate valve, 3- parallel single gate valve, 4- parallel double gate valve, 5- dark pole single wedge gate valve, 6- dark bar wedge gate valve

- Q: Notes on flat gate valves

- internal structureThe 1 seat O ring seal and preload floating seat structure, so that import and export of two-way valve seal plate; and the structure of the normal valve opening and closing torque only 1/2, can easily open and close valves2. when fully open, the channel is smooth and straight, the flow resistance coefficient is extremely small, and there is no pressure loss. The pipeline can be cleaned through the hair bulb3 the packing structure with the ability of self sealing, without frequent adjustment, opening and closing very lightweight, and reliable seal, the stuffing box is arranged at the auxiliary seal oil into the structure, absolutely reliable sealing performance, thereby achieving zero leakage; solve the shortcomings of the general valve packing leakage of the most vulnerable4., when the flat gate valve is closed, it can automatically unload the inner cavity high pressure, and ensure the safe use5., fully enclosed structure, good protection performance, can adapt to all-weather requirements6., the valve seat sealing structure should be elastic, preload, upper and lower sealing seat at the same time sealed structure. The valve seat and the seal are always face to face sealed.The 7. seat has self-cleaning function and is free of direct airflow during valve opening or closing. The seat shall be made of lubricated, non wearing material.8. valve actuator failure will not affect the other parts of the valve, maintenance and replacement work can be carried out without removing the valve.9. yoke sleeve aluminum bronze yoke sleeve with pin type thrust bearing to minimize operation torque.10. stem - thread length until bracket; dowel and spot welding; stability.11. pressure seal - simple construction, with sectional retaining rings and silver plated low carbon steel gaskets, helps to remove and achieve the best bonnet seal.12. seat ring - welded seat ring is perpendicular to the flow channel and is easy to maintain.

- Q: The legend of gate valve and stop valve

- Compared with the cut-off valve, the main advantage is that the flow resistance is small, the flow resistance coefficient of ordinary gate valve is about 0.08~0.12, while the ordinary cut-off valve resistance coefficient is about 3.5~4.5. Opening, closing force is small, the medium can flow in two directions. The disadvantage is that the structure is complex and the height is large. The sealing surface is easy to wear. The sealing surface of the valve must be forced to close the valve to achieve sealing, in the same caliber, work pressure and the same drive device, the drive valve torque is 2.5~3.5 times the gate valve. This point should be noticed when adjusting the torque control mechanism of the electric valve.The sealing surface of the stop valve contacts each other only when the valve is completely closed, and the relative sliding amount between the valve core and the sealing surface is very small, so that the wear of the sealing cover is very small. The sealing surface of the valve cover, mostly due to the spool and sealing surface before the debris, or because of the closed state is not tight, causing the medium of high-speed erosion caused by.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1993 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; East Europe; West Europe; East Asia; Mid East |

| Company Certifications | ISO9001:2008;CE;API-6D;OHSAS18001:2007 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | above 100 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 89,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

China cheaper Gate Valve

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches