GATE VALVE NON-RISING STEM METAL SEATED DUCTILE IRON JIS

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | China | Model Number: | JIS 10K | Brand Name: | CMAX |

| Shape: | Round | Special Use: | Water | Standard: | JIS, AISI, ASTM, GB, DIN, EN, Other |

| Application: | all sectors | Dimensions: | 40mm to 600 mm | Certification: | ISO/ CE |

| Structure: | Gate | Pressure: | Medium Pressure | Temperature of Media: | Normal Temperature |

Packaging & Delivery

| Packaging Details: | STANDARD/EXPORT PACKING/AS PER CLENTS REQUIRMENT |

| Delivery Detail: | 3-4 WEEKS /AS PER CLIENTS REQUIRMENT |

Specifications

Cast Iron JIS Non-Rising Stem Gate Valve

Certificate:ISO9001,ISO14001,CE,API,KS,GOST

Size from DN40-DN600

Cast Iron JIS-10K Rising Stem Gate Valve

Certificate:ISO9001,ISO14001,CE,API,KS,GOST

Size from DN40-DN600

Face to Face:JIS-10K

Flange:JIS-B2212

Valve Body,Bonnet:Cast Iron

Disc:Cast Iron

Seats:Brass

Stem:SS410

Hand Wheel:Cast Iron

Nominal Pressure:10K

Strength Testing:2.1Mpa

Seats Testing:1.6Mpa

1.Inspection:Foundry in-house; 100% Water Pressure Test ;Third Party inspection available upon request ..

2.Packing: As per the customer requirement .

3.Delivery Date:30 days ; According to the quantity .

4.Payment: 30% by T/T in advance, the balance before Shipping .L/C.D/P.

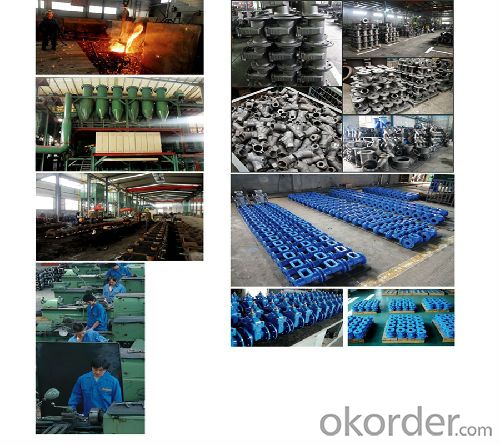

1. 10 years Industry and export experience

2. Extensive product range with good quality

3. Professional laboratory ,research and development team

4. Strictly test and quality control

5. Timely delivery and good after-sale service

6. Produce as per customer requirement

Welcome to contact us !

- Q: The difference between cut-off valve and gate valve

- The working principle is different. The stop valve is an upward stem type, and the handwheel rotates and rises with the stem. Valve is hand wheel rotation, stem upward movement. Flow is not the same, the gate valve requires full open, the cut-off valve is not the same. The gate valve has no inlet and outlet direction requirements, and the cut-off valve has the required inlet and outlet!Gate valve and stop valve are shut-off valve, is the most common two valves.From the exterior, the gate valve is shorter than the cut-off valve, especially the bar valve needs a higher height space. Valve sealing surface has a certain degree of self sealing capacity, its spool depends on the media pressure tight contact with the valve seat sealing surface, to achieve tight leakage. Wedge gate valve spool angle is generally 3~6 degrees, when forced to shut down excessive or temperature changes of the valve core is easy to die. Therefore, high temperature and high pressure wedge gate valve, in the structure have taken certain measures to prevent spool stuck. The valve in the opening and closing valve and valve seat sealing surface contact and mutual friction is always so easy to wear sealing surface, especially in close off the valve, the valve before and after the great pressure, sealing surface wear is more serious.

- Q: What is the difference between the model z81x-16q and z81x-16c of the groove gate valve?

- Not 16qIs 16p, the former body is stainless steel, and the latter body is carbon steel

- Q: What else, P54140V, 170V? What do they mean?

- P work pressureP54 temperature at 540 degrees of work pressureThe pressure at P54 100 is 540 at the temperature of 100barV valve for chromium molybdenum vanadium steelP54 pressure 140V temperature at 540 DEG C for 140bar valve for chromium molybdenum vanadium steelP54 pressure 170V temperature at 540 DEG C for 170bar valve for chromium molybdenum vanadium steelFrom the JB/T4018 "valve type model preparation method"The standard unit is MPa, but it is usually used in bar

- Q: How big valves and fittings need flange installation, such as gate valves, DN50, DN80 and the like?.

- Specifically, look at the pressure of the pipeline, the environment is not big, if large with flange connection, usually hoop or wire can be connected.

- Q: Gate valve type Z40Y, Z40H letters - what does that mean?

- According to the provisions of the JB/T 308-2004 valve type programming method:Z== gate valve4== connection: flange0== structure: wedge type elastic RAMY== sealing surface material: hard alloyH== sealing surface material: Cr13 stainless steel

- Q: What is the difference between an elastic gate valve and a rigid gate?

- One is cast iron, intermediate rubber gate, one is cast steel, and the other is steel flashboard,

- Q: What do gates, Z15T-10, Z15W-16T, Z45T/W-10, Z41T-10 mean?

- 7-, dark bar parallel gate valve, parallel gate valve 9- dark bar;5, sealing materials or lining materials were used R- T- austenitic stainless steel, copper alloy, X- rubber, S- plastic, N- nylon, F- fluorine plastic, H-Cr series stainless steel, hard alloy Y-, J- rubber, M- Monel alloy, Tc- ceramics;6, the body material code Z- K- gray cast iron, malleable cast iron, Q- ductile iron, copper and T- alloy, C- steel, P- chromium nickel stainless steel, R- stainless steel chromium nickel molybdenum, chromium molybdenum vanadium steel V-.For example: for electric, flange connections, Ming Liang wedge double gate, the sealing surface material directly processed by the body, nominal pressure PN0.1MPa body material for gray cast iron gate valve: Z942W-1 electric wedge double gate valve

- Q: What gate valve is the J41H-150LBDN100 gate valve?

- This is a stop valve, not a gate valve.Gate valve means Z41H-150LB-DN100Wenzhou shintex Valve Manufacturing Co. Ltd.0577Eight thousand six hundred and ninety-oneSeven thousand five hundred and sixteenCall

- Q: The main question is, what are the functional differences in which case?

- The gate (gate valve) is a gate opening and closing parts, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle gate valve. The direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle.Gate valve advantages: 1, fluid resistance is small,.2, opening and closing more labor-saving,.3, medium flow unrestricted, not disturbed flow, do not reduce pressure,.4, simple shape, structural length is short, manufacturing process is good, a wide range of applicationsValve shortcomings: 1, between the sealing surface is easy to cause erosion and abrasions, maintenance is more difficult,.2, big size, open need some space, opening and closing time is long,.3, the structure is more complex

- Q: Notes on flat gate valves

- Use, maintenance, maintenance and precautions1. valve before leaving the factory have made strength and sealing test, the use of all connections should maintain the initial state.2. this series of valve operating handwheel is marked with open and close rotary direction, and the upper part of rod is equipped with open and close height gauge for regulating indication.3. when the valve and pipeline welding, the valve should be opened, appropriate to protect the neck with moisture, minimize heat conduction, to prevent damage to the sealing packing parts.4. when the valve is closed, the lever shall not be used. When the gate is closed to the top, the handwheel shall be turned 1/2 so that the gate is in a floating state.5. in the use of the valve should be regularly to the valve cap injection grease joint into the quantitative grease.6., the valve in use, such as vulnerable parts and leakage, should be replaced in time.7., the valve in the overhaul process, the cavity should be cleaned, the assembly should be added to the transmission parts of grease.8. valve storage during the shutdown, the gate should be in the closed position, long-term storage should be placed in ventilated dry place, regular inspection and maintenance.

Send your message to us

GATE VALVE NON-RISING STEM METAL SEATED DUCTILE IRON JIS

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords