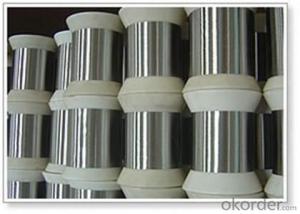

Galvanized Wire 0.13mm for Kitchen Scrubber /Mesh Scourers /Cleaning Ball

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Tons m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Kitchen scrubber wire :

Dia:0.13mm 0.18-0.27mm,Tolerance:+/-0.005mm

Tensile Strength:650-950n/mm2

Zinc Thickness:more 7g/m2

kitchen scrubber wire is mostly used to make staple,brush,U-type nail,net, tub handle,mesh scourer and others cleaning products.

Size | Size Tolerance | Tensile Strength | Zinc Coat Thickness |

mm | +/-mm | n/mm2 | g/m2 |

0.13 | 0/-0.01 | 1000-1250 | 5 |

0.18 | 0/-0.01 | 750-950 | 7 |

0.20 | 0/-0.01 | 750-950 | 8 |

0.22 | 0/-0.01 | 700-850 | 9 |

0.24 | 0/-0.01 | 650-800 | 10 |

0.27 | 0/-0.01 | 650-800 | 11 |

0.36 | 0/-0.01 | 1000-1250 | 5 |

0.48 | 0/-0.01 | 1000-1200 | 5 |

0.55 | 0/-0.01 | 950-1210 | 5 |

0.59 | 0/-0.01 | 950-1150 | 5 |

0.70 | 0/-0.01 | 950-1150 | 5 |

0.72 | 0/-0.01 | 950-1150 | 5 |

0.78 | 0/-0.01 | 9501150 | 5 |

0.88 | 0/-0.01 | 950-1150 | 5 |

0.96 | 0/-0.01 | 950-1150 | 5 |

1.21 | 0/-0.01 | 950-1150 | 10 |

1.37 | 0/-0.01 | 950-1150 | 18 |

1.59 | 0/-0.01 | 950-1150 | 18 |

1.83 | 0/-0.01 | 950-1150 | 18 |

- Q: What are the benefits of sanitation

- The protection equipment and make it is not too bad

- Q: Is it better to clean insulators with ultrasonic cleaning equipment or to clean them?

- The question is not clear, do you want to know its function or what? Ultrasonic cleaning machine, I ever did for cleaning artifacts such as metal and glass surface oil pollution, dust effect is very good, now the application is quite widespread, especially in auto parts, circuit boards, and solar wafers. If you buy a large scale of 40-600,000, small four, five thousand to 10,000, the individual factory in huaibei is not much, I can't imagine what kind of work you do.

- Q: How to keep the equipment clean

- The equipment needs to protect the electric motor circuit and the structure that need to adjust often is good! ~

- Q: What is the pool cleaning equipment

- Disinfection system (water treatment of swimming pool is very important, the water quality is not up to the standard to affect the opening) : Metering pump Drug delivery; Ozone generator. Lighting system (underwater lamp beautification swimming pool) : Pool wall lamp; Waterproof cable. Fully automatic thermostat (the temperature of the water in the swimming pool) : Fully automatic heating furnace; Water and water heat exchanger (commonly known as plate change); Temperature controller; Electric valve. Cleaning equipment (pool brush, leaf net, telescopic rod, suction head, wire brush). 5, the pool bank facility (escalator, departure stage). Water quality monitoring equipment (water quality monitor, test water box, water temperature meter). Water treatment pipe fittings.

- Q: What is the difference between industrial cleaning equipment and general cleaning equipment?

- The performance and usage difference of industrial high pressure cleaning machine and commercial class high voltage cleaning machine Under the same technical parameters (pressure flow), industrial high pressure cleaner can effectively continuously working time is more than commercial grade high pressure cleaner can effectively work time continuously, industrial-grade pressure washer pump head and the whole machine volume is greater than that of commercial grade high pressure cleaner pump head and the whole machine volume, the value of industrial high pressure cleaner and service life is far greater than the value of commercial grade high pressure cleaner and service life. Industrial washing machine, just as its name implies is to meet the industrial and mining enterprises such as poor environment, long running time and large amount of cleaning and higher requirements on the cleaning efficiency of unit designed for the professional cleaning machine; The design and manufacturing of the product are all about the convenience of the future and the purpose of fighting the complex environment. The industrial type cleaning machine is used to adapt to different working and mining conditions. The product is based on maintainability; The equipment is reliable, leather and durable, and its lifespan is more than three times that of other washing machines. The industrial cleaning machine is usually heavy steel structure, reliable and durable. The configuration of overpressure, overload protection, high heat value, high heat efficiency, quiet work and low noise. Low cost of heating and maintenance. Professional industrial cleaning machines are more suitable for environmental factors such as the weather, water quality, wind sand and ground, etc., and have longer life.

- Q: What cleaning equipment does the factory clean equipment need?

- A, plant, Workshop area mainly include workshop and warehouse, the characteristics of the environment is that difficult to clean and dirty, the area is large, the environment need to be efficient driving type washing machine, charge can clean the tens of thousands of square meters area, effectively improve the level of clean. Second, office space The office area usually is laid carpet according to need, so general can not use the ground machine. We need to use a vacuum cleaner for the daily cleaning of the carpet, and if we are not careful with the carpet, we need to use the suction machine. Carpet in the middle of care we need to use dry foam carpet cleaning machine, foam carpet cleaning machines and carpet washing machine and spray carpet smoking machine equipment, such as carpet of general and one month to do a thoroughly clean, can effectively remove dirt. When the carpet is cleaned in the long run, it is difficult to clean thoroughly in the middle and late stage, and then you need to use a carpet washing machine. The carpet washing machine can be used in the middle and later of the carpet to clean the carpet effectively, can make carpet the refurbishment work, the surprise that can surprise unexpectedly! Outdoor squares and open Spaces These places usually area is large, open, open, although it is difficult to clean, but not general cleaning requirements is very high, you just need to keep the floor clean. We recommend sweeping machines to remove dirt and dirt from the ground and keep it clean.

- Q: Article 84 in GMP, the production equipment shall be cleaned according to the operating procedures specified in detail. Production equipment cleaning procedures shall stipulate detailed and complete cleaning methods, cleaning with the name of the equipment or tools, cleaning agents and preparation method, to remove the previous batch identification methods, protect already clean equipment before use from pollution methods, already clean equipment for the longest time limit, preserved...

- This time is dirty time, oneself according to the production requirements for 3 days, 3 days after completing equipment use clean, if qualified, cleaning validation then SOP can regulation equipment should be used in within 3 days from the end of the cleaning.

- Q: The oil can be cleaned by the tank cleaning and the cleaning of the tank is the cleaning of the machine

- The tank cleaning industry at present, the general take artificial cleaning, mechanical equipment cleaning tank is just rise recently, really can do mechanical cleaning also does not have a few, and some manufacturers are generally abroad, prices more expensive each device also need to around 10 million, as currently on the market what the robot cleaning tank while the price is cheaper, but the technology is relatively insecure, we cleaning company is this year just at the beginning of the year on a mechanical cleaning equipment, the effect is good, the key is cheap compact result, oil recovery rate can reach 90%, in the process of cleaning is content value.

- Q: Clean the cleaning parameters of the equipment

- The main still should see you clean thing, clean the rough, no strict requirements to surface with low frequency is ok, but for some mesh class cleaning high frequency, it is best to this can reduce the workpiece of ultrasonic cavitation effect. Secondly depends on the choice of cleaning medium, weak alkaline medium SUS304 steel can, weak acid or not enough, easy to form in acoustic surface acidification, steel easy ageing.

- Q: How do you clean the household central air conditioner

- It is mainly the filtration grid that is cleaning outlet, if can ask professional person to clean the wind channel is better

Send your message to us

Galvanized Wire 0.13mm for Kitchen Scrubber /Mesh Scourers /Cleaning Ball

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100Tons m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches