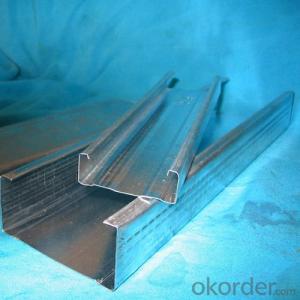

Galvanized Steel Drywall Runner and Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

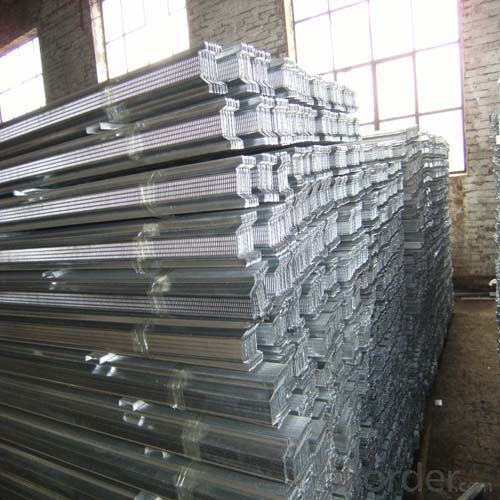

Name: Galvanized steel profile/metal stud/drywall stud

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized stee strip zinc coating is 80-180g/m2.

3.Warm sales in Middle East , Africa , Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services

4. The specification can follow up customer requirments.

5. Advanced equipment can make sure exactly size, high quality products.

Galvanized steel profileTechnicology:

1.adopting high-grade quality hot-dipped galvanized steel,

2.The products surface zero spangle,and intensity toughness, besides, it can add 20% more than common product.

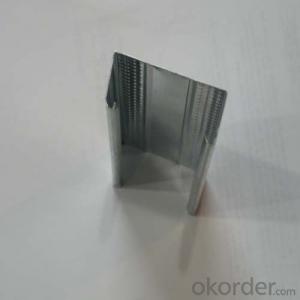

Steel stud

Made from hot dipped galvanized steel strip

Partition wall of steel structure buildings

GB/T3381.1-93

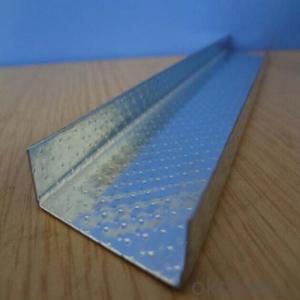

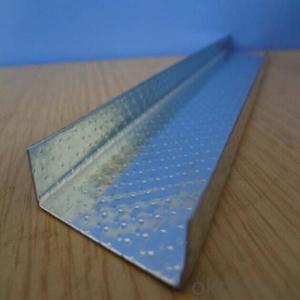

Features of steel stud

1, advanced equipment, production technology, advanced detection methods of science, the product surface, rolling, high precision, beautiful shape, straight;

2,Using the high quality continuous hot-dip galvanizing cold-rolled coil for the base material ,material evenly ,moderate hardness , light weight ,fireproof, combination convenience , Not subject to seasonal effects, the construction simple and quick, greatly shortening the duration and improve the working efficiency;

3, the steel stud have good corrosion resistance ability, long service life;

4, Cross-section structure is reasonable, humane design: Keel, Vice keel and vertical played pitting self-tapping screw designed to effectively prevent sideslip, improve the construction speed, Vice-keel edge of the stiffener designed to enhance the steel keel, anti-subsidence more capable, the level of vertical keel edge design makes perfect fastening, an increase of product application design

Application

1,Supermarket, marketplace

2,Underground, air port, bus station

3,Building lobby,metro station

4,Hotel, restaurant,railway station

5,School, office, meeting room ,hospital

6.commercial building

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures:

- Q: What is the decoration of the wall? Lightweight bricks Or light steel keel frame?

- Well, I think so, I found two companies were quoted, the price is almost, but the listed materials are not the same.

- Q: Shanghai light steel keel ceiling wall how much labor costs?

- Do not know how much of your area may be a little expensive point of the ceiling 10 yuan / square wall 80 / side less expensive to the point is not the same everywhere, roughly in the 20 to 25 or so labor price.

- Q: What is the light steel keel gypsum board partition? What are the characteristics?

- 1. Wall shrinkage deformation and board cracks: the reason is the vertical keel tight top and bottom keel, no extension of the amount of stretch, more than 2m long wall is not controlled deformation joints, resulting in wall deformation. The wall should be left around the gap 3mm, which can reduce the temperature and humidity caused by the deformation and cracks. 2. Light steel skeleton connection is not strong, because the local node does not meet the structural requirements, the installation of local nodes should be strictly in accordance with the provisions of the law. Nail spacing, location, connection method should meet the design requirements.

- Q: To warm the above has been tiled, with light steel keel to build a wall, how to fix the keel?

- With a lightweight partition, brick, and do not do gypsum board wall.

- Q: Light steel keel partition wall door how to do

- The wall keel to use the national standard light steel wall keel - the thickness of the strength of only;

- Q: I would like to have a toilet in the house, bathroom with mineral wool board cut off or light steel keel gypsum board line?

- These two estimates are problematic, you can use light steel keel cement pressure plate nail steel wire mesh paint, do waterproof post-paste wall tiles, the following also do waterstops

- Q: Light steel keel wall gypsum board seams how to deal with? Including smallpox

- First with gypsum slit smooth, and then paste the old white leather paste with kraft paper, as long as the joints have to deal with. Better than the kind of gauze belt. My family used

- Q: Light steel keel gypsum board wall panels have cracks how to do?

- The original piece of putty knock down, from the new batch of putty on it

- Q: Light steel keel gypsum board partition wall construction practices and construction process What is the difference?

- The practice is to first play on the ground and shed on the corner keel must be vertical after the installation of the main keel times the keel installed in the plaster board plaster brush latex paint difference is stronger than the keel cost is higher than the wood keel

- Q: Light steel keel installed security door how loaded really

- It is recommended to install two square steel pipes vertically and fixed on the concrete floor and floor. The security door is mounted on the square steel pipe

Send your message to us

Galvanized Steel Drywall Runner and Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords