Galvanized/Aluzinc Steel Sheet with Best Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

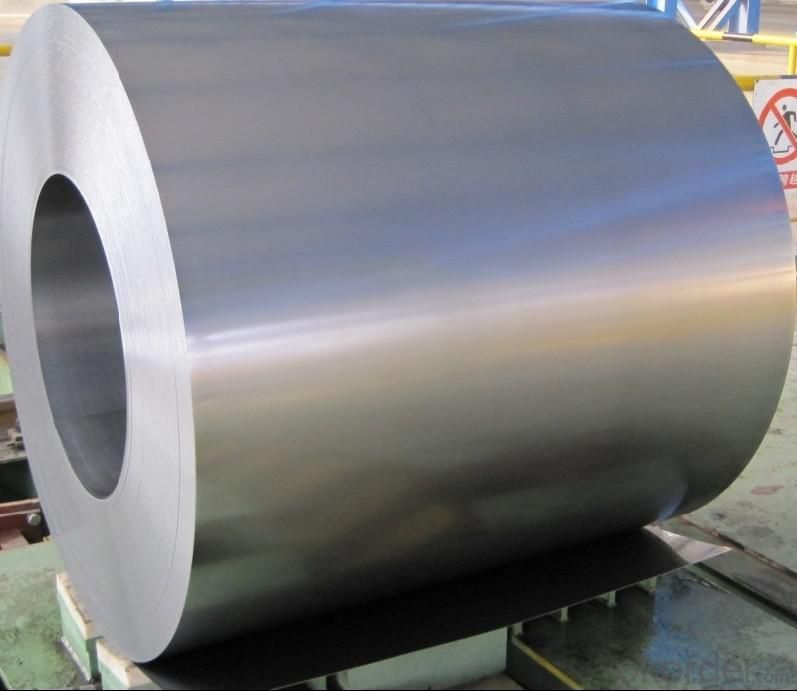

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

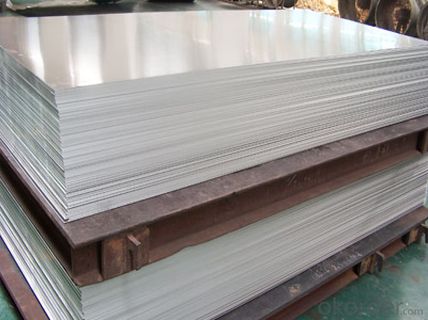

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

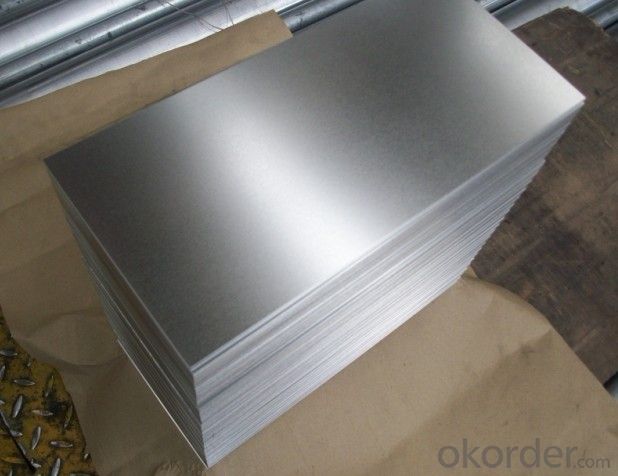

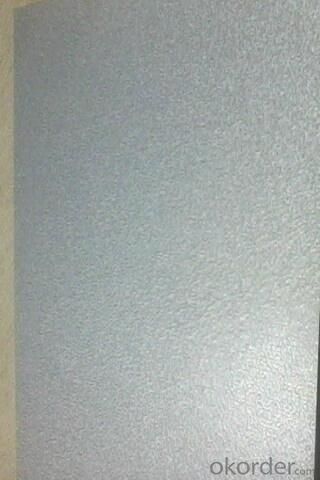

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

| Processability | Yield strength | Elongation % | Elongation % | 180°cold-bending |

| Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

| Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

| Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

| Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

| EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What is the maximum thickness available for steel sheets?

- The maximum thickness available for steel sheets can vary depending on the specific type and grade of steel being used, but it can typically range from a few millimeters to several centimeters.

- Q: Are steel sheets suitable for solar panel mounting?

- Yes, steel sheets are suitable for solar panel mounting. They provide a strong and stable base for the panels, ensuring they are securely installed and can withstand various weather conditions. Additionally, steel sheets are durable and long-lasting, making them a reliable choice for solar panel mounting systems.

- Q: What are the different methods of protecting steel sheets from scratches?

- There are several methods of protecting steel sheets from scratches. One common method is applying a protective coating or paint on the surface of the steel sheet. This coating acts as a barrier and prevents scratches from occurring. Another method is using a temporary protective film or tape on the steel sheet. This film or tape can be easily applied and removed, providing a temporary safeguard against scratches. Additionally, using padded or protective packaging during transportation or storage can help prevent scratches. Implementing proper handling and storage procedures, such as using non-abrasive materials and avoiding stacking or sliding steel sheets, can also minimize the risk of scratches.

- Q: How do steel sheets perform in terms of wear resistance?

- Steel sheets generally perform very well in terms of wear resistance. Steel is known for its strength and durability, and steel sheets are no exception. They are able to withstand heavy loads, abrasion, and impact, making them suitable for a wide range of applications where wear resistance is crucial. Additionally, steel sheets can be further enhanced with surface treatments or coatings to improve their wear resistance even more. Overall, steel sheets are a popular choice for industries that require materials capable of withstanding wear and tear over extended periods of time.

- Q: How do you transport steel sheets safely?

- Steel sheets can be transported safely by following some key guidelines. Firstly, ensure that the sheets are securely stacked and bundled together to prevent them from shifting during transportation. It is recommended to use sturdy pallets or racks to support the weight and avoid any damage. Additionally, using appropriate straps or chains to secure the bundles further enhances safety. Lastly, careful handling and loading onto the transportation vehicle, while considering weight distribution, will ensure the safe transportation of steel sheets.

- Q: What are the environmental impacts of steel sheet production?

- The environmental impacts of steel sheet production include carbon emissions from the burning of fossil fuels during the manufacturing process, the consumption of large amounts of energy and water, and the generation of waste and pollutants such as particulate matter, sulfur dioxide, and nitrogen oxides. Additionally, the extraction of raw materials for steel production, such as iron ore and coal, can lead to deforestation, habitat destruction, and soil erosion.

- Q: Are steel sheets suitable for elevator shafts?

- Indeed, elevator shafts can be suitably constructed using steel sheets. Steel, renowned for its robustness, endurance, and fire-resistant qualities, is extensively utilized in the construction sector. Considering the demands of elevator shafts, which necessitate a material capable of enduring substantial weights, maintaining structural integrity, and meeting safety regulations, steel sheets perfectly meet these prerequisites. Opting for steel sheets grants the flexibility to fabricate them into the desired dimensions and contours, facilitating creative design possibilities. Moreover, steel is effortlessly maintainable and repairable, guaranteeing the prolonged lifespan of the elevator shaft.

- Q: What are the advantages of using steel sheets?

- There are several advantages of using steel sheets. Firstly, steel sheets are highly durable and have a long lifespan, making them a cost-effective option in the long run. Secondly, steel sheets have high strength-to-weight ratio, making them lightweight and easy to handle while still providing excellent structural integrity. Additionally, steel sheets are resistant to corrosion and can withstand extreme weather conditions, making them suitable for outdoor applications. Furthermore, steel sheets are versatile and can be easily fabricated into various shapes and sizes to meet specific project requirements. Lastly, steel sheets are recyclable, making them an environmentally friendly choice.

- Q: What is the average weight of a steel sheet per square meter?

- The weight of a steel sheet per square meter can differ based on its thickness and the type of steel in use. Nevertheless, a rough approximation for mild steel sheets is approximately 7.85 kilograms per square meter. It should be emphasized that this weight may slightly fluctuate according to the precise composition of the steel and any extra coatings or treatments applied to the sheet.

- Q: What are the applications of steel sheets in construction?

- Steel sheets have a wide range of applications in construction due to their exceptional strength, durability, and versatility. Some of the key applications of steel sheets in construction include: 1. Roofing and cladding: Steel sheets are commonly used for roofing and cladding in both residential and commercial buildings. They provide a weather-resistant and long-lasting solution, protecting the structure from the elements. 2. Structural components: Steel sheets are utilized in the construction of structural components like beams, columns, and trusses. The high strength-to-weight ratio of steel allows for the creation of lightweight yet robust structures that can withstand heavy loads and seismic forces. 3. Flooring: Steel sheets are often used as flooring material in industrial buildings, warehouses, and factories. Their smooth surface makes it easy to clean and maintain, while their strength and fire-resistant properties provide a safe working environment. 4. Wall partitions: Steel sheets are commonly employed in the construction of wall partitions due to their stability and sound insulation properties. They can easily be cut and shaped to fit any design, allowing for flexible and customizable partition layouts. 5. Ductwork and HVAC systems: Steel sheets are widely used in the fabrication of ductwork and HVAC systems. Their smooth and airtight surfaces allow for efficient air movement and regulation, ensuring proper ventilation and temperature control in buildings. 6. Reinforcement: Steel sheets are often integrated into concrete structures as reinforcement. This helps to enhance the strength and load-bearing capacity of the building, making it more resistant to bending, tension, and compression forces. 7. Safety and security: Steel sheets are utilized in the construction of safety and security features such as doors, gates, and window frames. Their high strength and resistance to impact and vandalism make them an ideal choice for ensuring the safety and protection of a building. In summary, steel sheets are extensively used in construction for roofing, cladding, structural components, flooring, wall partitions, ductwork, reinforcement, and safety features. Their superior strength, durability, and versatility make them an essential component in various construction applications, contributing to the overall safety, longevity, and functionality of buildings.

Send your message to us

Galvanized/Aluzinc Steel Sheet with Best Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords