High Quality of Galvanized Steel Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Coil Description:

Hot-dip galvanized steel coil are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

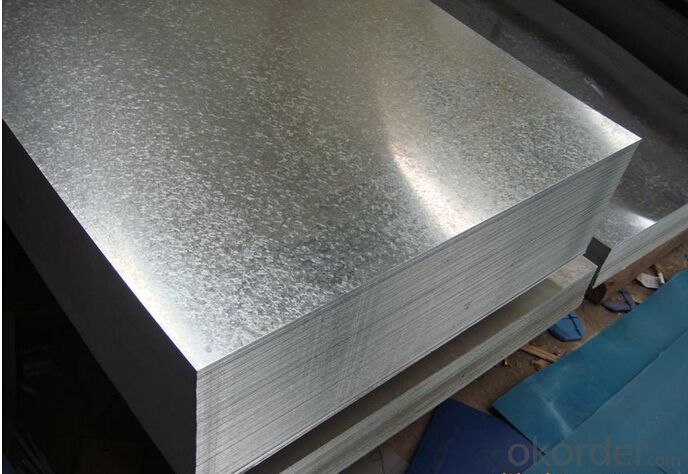

3.Hot-Dip Galvanized Steel Coil Images

4.Hot-Dip Galvanized Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: SPCC, SPCD, Q195, DX51D

Thickness: 0.15-5.0mm

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Galvanized

Application: Container Plate

Special Use: High-strength Steel Plate

Width: 600-1250mm

Length: depends

commodity: hot dipped galvanized steel coil

technique: cold rolled

thickness: 0.15-5.0mm

width: 600-1500mm

surface treatment: galvanized

zinc coating: 50-275g/m2

coil weight: 3-7 tons

coil ID: 508/610mm

spangle: zero spangle, regular spangle, small spangle, big spangle

payment term: by L/C or T/T

5.FAQ of Hot-Dip Galvanized Steel Coil

What’s the application of this product?

There are many applications for this product. For example, roofing, cladding, decking, tiles, sandwich walls, etc.

What’s the coating composition of Hot-Dip Galvanized Steel Coil?

The coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

- Q: Can steel sheets be used for solar panel manufacturing?

- Yes, steel sheets can be used for solar panel manufacturing.

- Q: What is muotileaved spring? What is the little leaf spring?

- Leaf: ranging from multiple pieces of the same length, width of sheet steel by adding together. Multi leaf spring of each leaf into superposition inverted triangle shape, the top plate is the longest, the bottom plate is the shortest, piece number and supporting the weight of the bus plate, plate more thick more shorter, more rigid spring. However, when the leaf springs are used for a long time, they slide and rub each other. The relative friction between the steel plates also causes spring deformation, resulting in uneven running.

- Q: Do the steel sheets have any sharp edges?

- Indeed, sharp edges can be found on steel sheets. Throughout their production, steel sheets frequently undergo cutting or shearing processes, thereby resulting in the presence of sharp edges. It is of utmost importance to exercise caution when dealing with steel sheets and to employ suitable protective gear, like gloves, while working with them, in order to prevent any harm arising from the sharp edges.

- Q: Are steel sheets suitable for food processing facilities?

- Yes, steel sheets are suitable for food processing facilities. Steel is a durable and hygienic material that is resistant to corrosion, easy to clean, and can withstand high temperatures. It is commonly used in food processing facilities to ensure food safety and maintain a clean and sanitary environment.

- Q: Are steel sheets resistant to warping under heat?

- Yes, steel sheets are generally resistant to warping under heat due to their high melting point and excellent thermal conductivity.

- Q: What is the difference between a smooth and patterned steel sheet?

- A smooth steel sheet typically has a plain, uniform surface without any visible patterns or textures. It has a consistent and sleek appearance, making it suitable for applications where a clean, modern look is desired. On the other hand, a patterned steel sheet features various designs or textures that are embossed or etched onto the surface. These patterns can range from simple geometric shapes to intricate motifs. Patterned steel sheets are often chosen for their decorative appeal and ability to add visual interest to a space. They can be used in architectural elements, such as wall panels or ceiling tiles, to create a unique and artistic effect. In terms of functionality, smooth steel sheets may offer slightly better corrosion resistance due to their smoother surface, making them suitable for applications where protection against rust is important, such as in outdoor or marine environments. Conversely, patterned steel sheets may have reduced corrosion resistance due to the variation in surface texture, potentially offering less protection against rust. Overall, the choice between a smooth and patterned steel sheet depends on the desired aesthetic, functional requirements, and the intended application.

- Q: Are the steel sheets suitable for food-grade applications?

- Yes, steel sheets can be suitable for food-grade applications. Stainless steel in particular is commonly used in the food industry due to its excellent corrosion resistance, durability, and ease of cleaning. It is non-reactive and does not release any harmful substances into food, making it a safe choice for food storage, processing, and transportation. Additionally, stainless steel is resistant to high temperatures and can withstand rigorous cleaning and sanitization processes, making it ideal for use in food-grade applications. However, it is important to ensure that the steel sheets meet the necessary food-grade standards and regulations before using them in any food-related setting.

- Q: What are the different surface textures for galvanized steel sheets?

- There are several different surface textures for galvanized steel sheets, including smooth, spangled, matte, and diamond.

- Q: What is the difference between galvanized and non-galvanized steel sheets?

- The primary difference between galvanized and non-galvanized steel sheets lies in their ability to resist corrosion. Galvanized steel sheets have a layer of zinc coating that acts as a protective barrier against rust and other forms of corrosion. This zinc coating not only adds durability and longevity to the sheets, but also makes them highly resistant to weathering and moisture exposure. On the other hand, non-galvanized steel sheets lack this zinc coating, making them more susceptible to rust and corrosion. Without the protective layer, non-galvanized steel sheets may corrode when exposed to moisture or harsh environmental conditions. In addition to their resistance to corrosion, the appearance of galvanized and non-galvanized steel sheets also differs. Galvanized steel sheets have a distinct silver-gray finish due to the zinc coating, giving them a more visually appealing look. In contrast, non-galvanized steel sheets have a plain, matte appearance. Considering cost, galvanized steel sheets are generally more expensive than non-galvanized ones. This is because the zinc coating adds an extra layer of protection and enhances the overall quality of the sheets. In summary, the main distinction between galvanized and non-galvanized steel sheets lies in their resistance to corrosion, appearance, and cost. Galvanized steel sheets offer superior protection against rust and corrosion, have a more attractive appearance, but come at a higher cost compared to non-galvanized steel sheets.

- Q: Are steel sheets suitable for architectural cladding?

- Yes, steel sheets are suitable for architectural cladding. Steel cladding offers durability, strength, and versatility in design, making it a popular choice for architects. It can be easily formed into different shapes and sizes, providing flexibility in creating unique building facades. Additionally, steel cladding is resistant to weather conditions, fire, and pests, making it a long-lasting and low-maintenance option for architectural applications.

Send your message to us

High Quality of Galvanized Steel Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords