Galvanized 2.5m Standard Vertical Kwikstage System Scaffolding CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Galvanized 2.5m Standard Vertical Kwikstage System Scaffolding

Type:

Material:

Construction Properties:

Lapping Form:

Framework:

Supporting Mode:

Erection Position:

Scaffolding Part Type:

Move Method:

Structural Style:

Place of Origin:

Surface:

Material.:

Thickness:

Descriptions of Galvanized 2.5m Standard Vertical Kwikstage System Scaffolding

Kwikstage Scaffolding is a multi-purpose modular scaffold system which can be used for all forms of access and support structures in the building and construction industries, ship buliding, offshore construction and industrial maintennace.

Details of Metal kwikstage Scaffolding

1. Metal kwikstage scaffolding system is a new type of selflock scaffolding which is very popular in Oceanian,African construction.

2. Metal kwikstage scaffolding System is suitable for both inside concrete slab supporting and outside masonry Construction multi-purpose for construction.

3. Metal kwikstage scaffolding systemstandard is weld with a plate every 600mm which can join ledgers at 90 degree.

4. Metal kwikstage scaffolding system ledger is a horizontal member with a blade at each end for insertion into the standard plate.

5. kwikstage scaffolding system is quick to erect and strip which has completely replaced other scaffolding.

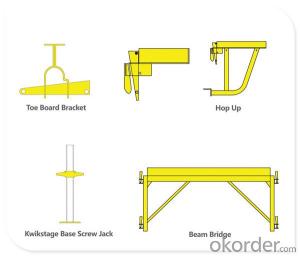

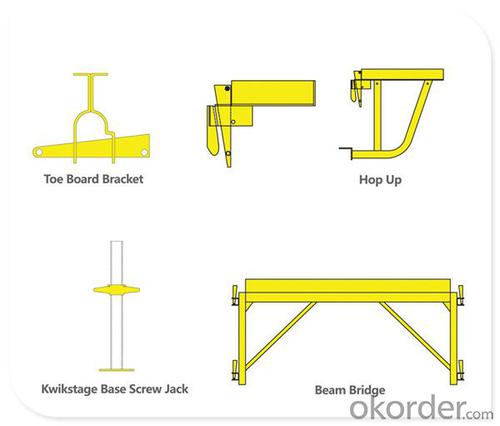

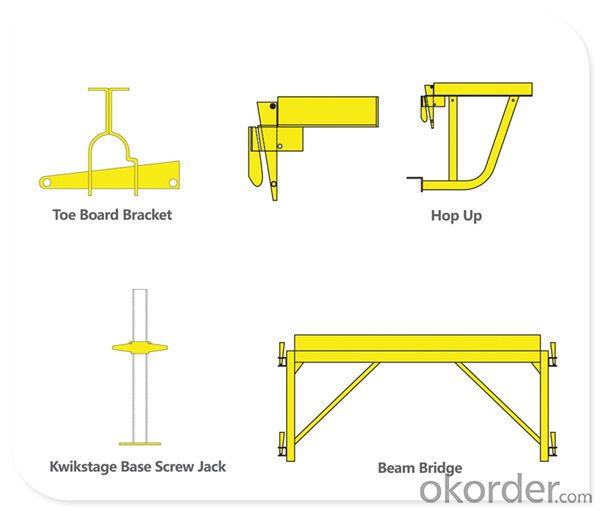

The Accessories of Galvanized 2.5m Standard Vertical Kwikstage System Scaffolding

The main items of Kwikstage scaffolding system

ITEMS SPECIFICATION WEIGHT STANDARD

(VERTICAL)48.3*4.0*3000/2500/2000/1500/1000mm

painted/hot dip galvanized/ect.

steel pipe16.94/14.34/11.53/8.86/6.13kg LEDGER

(HORIZONTAL)48.3*3.2*2400/1800/1200/700mm

painted/hot dip galvanized/etc.

steel pipe9.1/6.85/5.13/3.24kg TRANSOM 2400/1800/1200/700mm

painted/hot dip galvanized/etc.19.92/12.08/10.79/7.79kg BRACE 2400*2000mm/2500/3000mm

pained/hot dip galvanized/etc.9.38/10.35/11.41kg HOPUP BRACKET one board/two board/three board

painted/hot dip galvanized/etc.1.84/4.99/8.58kg The other items of Kwikstage scaffolding system

TIE BAR 2400/1800/1200/700mm

painted/hot dip galvanized/etc.5.41/4.15/2.77/1.72kg STEEL BOARD 2400/1800/1200/700mm

painted/hot dip galvanized/etc.14.5/10.93/7.68/4.94kg END TOE BOARD BRACKET as normal specification or as customers' drawing

painted/hot dip galvanized/etc.1.12kg TOE BOARD BRACKET as normal specification or as customers' drawing

painted/hot dip galvanized/etc.0.72kg BASE JACK and U HEAD 38*4.0*650mm/u head

painted/hot dip galvanized/etc.3.69/4.63kg FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: i need as much detail you can give me on these symbols in the book scarlet letter by Nathaniel Hawthorne. if you have any website references besides cliffs notes and spark notes i would greatly appreciate it!!!

- hey...i'm trying to figure out the same thing....weird.

- Q: What are the general specifications of bowl buckle scaffold?

- In fact, the conventional bowl buckle scaffold is made of 48 Q235 carbon steel pipe processing, pole specifications are 0.6m, 0.9m, 1.2m, 1.5m, 1.8m, 2.4m, 3.0m; crossbar specifications are 0.6m, 1.2m, 1.5m. The price of any product is determined by its consumption of materials and processing costs

- Q: What are the components of a mobile scaffolding

- The utility model relates to a standard steel pipe scaffold which is connected with the main structure of the wall and is connected with the main structure of the building.

- Q: Im hoping to get an industrial/scaffold piercing done at the very beginning of the summer holidays.Is it possible that they can be pierced with 2 separate pieces of jewellery rather than one bar.Also would it be healed in time to take it out once the holidays are over (6 weeks)??Please help??!?Thanks x

- Yep, some piercers prefer to do it that way. Just make sure you let them know that that's what you want when you go into the shop and they can accommodate you. No cartilage piercing is healed enough to remove in 6 weeks. Cartilage piercings can take anywhere from 6-12 MONTHS to fully heal.

- Q: Fastener type steel pipe scaffold composed of two components? What are the roles?

- Bowl buckle steel pipe scaffolding when using steel pipe, as a "single steel pipe scaffolding"; when using the steel cross bar, for the "steel pipe based scaffold".2.2 according to the vertical and horizontal transmission force between the vertical and horizontal1) the frictional force acting on the contact surface. That is, the friction force at the contact surface of the joint is pressed to support the load of the cross bar and is transmitted to the vertical rod;2) welding force. Most of the cross bar and vertical rod socket connection is used in this way, the door frame is also this way;3) direct pressure transmission. This method is more common in the horizontal bar placed in the top of the scaffolding;4) shear force of pin. That is to say, the connecting rod and the hole of the vertical rod are connected by the pin rod through the vertical connecting plate of the transverse rod to realize the double side shear action of the connecting rod and the pin rod. This method is rarely seen in the connection between the rod and the vertical rod.

- Q: Can you do the outer scaffolding?

- (2) the outer side of the scaffold must be provided with scissors, scissors width should not be less than 4 span, and should not be less than 6m, the angle between the diagonal rod and the ground is 45-60 degrees. The intersection points of the oblique bars are on the same straight line and are arranged along the height of the frame. (3) a diagonal rod of the scissors is buckled on the upright post, and the other inclined rod is buckled on the end of the small transverse rod, and the two ends are respectively fixed with a rotating fastener. All fixed pitch master node distance not greater than 15 cm

- Q: What is the bowl buckle scaffolding, bowl buckle scaffold what are the characteristics

- (1) main componentComponent for forming the main body of a scaffold. The vertical rod and the top rod are respectively provided with two kinds of specifications, and both sides of the rod are welded with a lower bowl buckle with a spacing of 600mm. If the vertical rod and the ejector rod are matched with each other for long use, the utility model can form an arbitrary height scaffold. Take a long pole, the joints should be staggered, the top layer and then leveling rod length two.

- Q: What are the common rules for calculating the amount of scaffolding works

- The independent brick (stone column) less than 3.60M in height, scaffold to construct the core column multiplied by the circumference of high calculation, the implementation of masonry scaffolding in the shelf; column 3.60M with column wise, the structure of the circumference of the core column height calculated by multiplying plus 3.60M, the implementation of masonry scaffolding outside the shelf (single row). Where masonry height exceeds 1.5m of the masonry are required to calculate the scaffolding.

- Q: He pushes a can over the scaffold at 15 meters and it takes 3.25 seconds for it to land.I keep doing the problem over and over. the Correct answer is 20.5 m/s, however I keep arriving to the solution of 17 m/s. I solved it by doing Vf^2 = Vi^2 + 2adwhere the initial velocity is zero and the acceleration is -g. I made my coordinate system so that down is negative in which the distance will be negative. This however, did not give me the correct answer. Am I right or is the book right?

- The initial velocity is not zero since the scaffold is moving upward when the can gets pushed over. And final velocity, vf, does not represent the speed of the scaffold (if that is what you're trying to solve). y = (vo)(t) - (1/2)gt? 15 m = (vo)(3.25 s) - (1/2)(9.81 m/s?)(3.25 s)? vo = +20.5 m/s

- Q: along with this question, -what does she think about during this time period?-how does she apprear on the scaffold? -who does she see and how does she feel?THANKS!!=]

- Here is a good analysis and summary from Shmoop.

Send your message to us

Galvanized 2.5m Standard Vertical Kwikstage System Scaffolding CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords