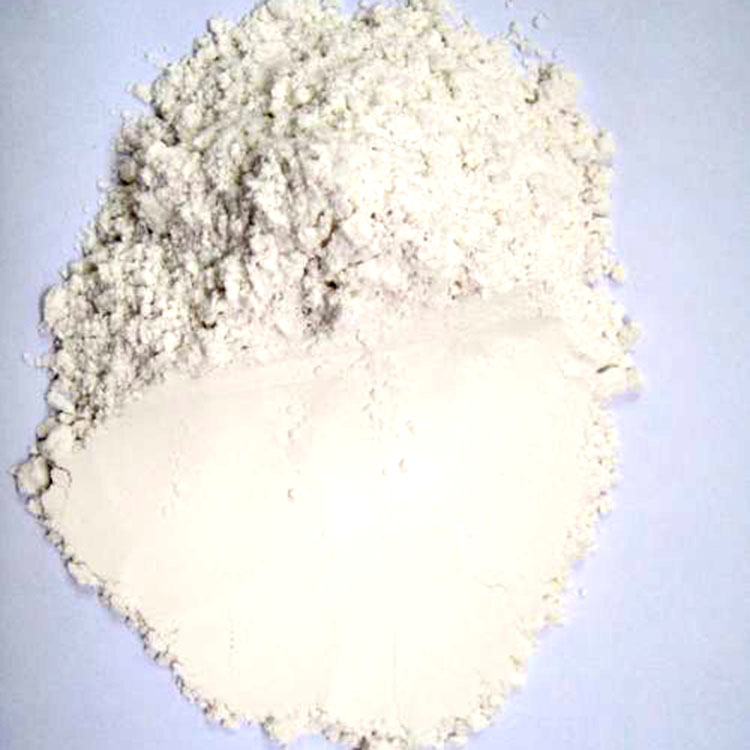

Raw Materials for Refractory - Fused Silica Powder 200mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT INFORMATION | |

Item | Fused Silica Powder |

Size | D50=9~11um |

Application | Epoxy insulation encapsulant material / Epoxy Molding Compound (EMC), Copper Clad Laminate (CCL), Electromagnetism Industry, Electronic Industry, Ceramic Industry, The Aerospace Industry, Glass Industry, Plastics Industry, Grinding Material Industry, Coating Industry, Investment Casting Industry, Thermal Insulation Product of Calcium Silicate, Refractory Material |

Model No. | R610 |

MOQ | 5 ton |

Material | natural silica rock after melting |

H.S. CODE | 25061000 |

PRODUCT CHEMICAL COMPOSITION AND PHYSICAL PROPERTIES | |

SiO2 | >99.99% |

Al2O3 | <0.015% 1000ppm |

Fe2O3 | <0.002% 50ppm |

Density | 2.2 |

Whiteness | >92% |

Moisture content | <0.05% |

Mohs hardness | 6.5 |

Igniting loss | <0.12% |

Appearance | powder |

- Q: what is best for making refractory insulation for Blast furnace, hot stove.

- clay brick, insulating brick can endure relatively high temperature and last longer than the general fireproof fiber.

- Q: Does anyone know the refractory temperature of fire-resistant glass?

- Ordinary glass will burst under sharp temperature difference of about 70-120 degrees and toughened glass of 200 degrees. It is not yet clear for the bursting temperature differences of the refractory glass. If the overall glass is heated evenly, it will have no significant change below 600 degrees, and it will deform with the increase of temperature until melting. The fire-resistant time of the glass you said is the time to heat the glass into the extreme temperature differences it can endure, which should not be more than 10 minutes

- Q: what's the classification of fireproof and thermal inuslation matertial?

- Inorganic thermal insulation material can do it, such as glass wool,rock wool,foam glass,etc. phenolic foam materials in organic foam material is special. phenolic foam not only has good thermal insulation properties but also can be composited with steel plate and other materials, A class thermal insulation materials that reach A class combustion performance include: rock (mine) wool, foam glass, EVB, etc. thermal insulation materials with A class combustion performance mainly include: phenolic aldehyde,gelatine powder polyphenyl granule, etc. thermal insulation material of fire barrier zone can use rock (mine) wool, foam glass, EVB and other materials with A class combustion performance.

- Q: What are the characteristics of magnesium fireproof plate

- Features: Glass magnesium plate is high temperature resistant, sound absorbing, and capable of preventing water, pests, dampness, corrosion, poison, pollution. Paint can directly be applied to the surface of the plate. Air nails are usable for the plate, to which ceramic tile can also be applied with good pigmentation. The plate is easy to decorate, has high strength, good flexibility when bending, and can be nailed, sawed, glued It can also be made into thermal insulation materials with a variety of compround composite insulation plate. Characteristic: Magnesium plate glass is high temperature resistant, sound absorbing, and capable of preventing water, pests, dampness, corrosion, poison, pollution. Paint can directly be applied to the surface of the plate. Air nails are usable for the plate, to which ceramic tile can also be applied with good pigmentation High strength, flexibility when bending, convenient for decoration. It can be sawed, nailed, and glued.

- Q: How long is the fire-resistant time of fireproof wooden door?

- The fire-resistant time of fireproof wooden door is about 1 hour. Fireproof wooden door refers to the door whose door frames, skeleton of the door leaf, door panels are made of timber or timber work and fire endurance reaches the provisions of "GB50045-95 design of tall buildings for fire protection". Fireproof door is one of devices for fire?prevention and separation of the building, generally used on the firewall, entrance and exit between stairs pipe shaft opening, which plays an important role in the reduction of fire losses.

- Q: What are refractory materials?

- Refractories can be divided to two categories based on the shape and three categories according to the chemical nature of acidity, neutralily and alkalinity. Alkaline refractory materials are magnesia-carbon brick, magnesia chrome brick, calcium magnesium brick and magnesia-chrome bricks. Neutural refractory mateial are high alumina brick, corundum brick and clay brick. Case-hardened refractory materials are castable, ramming mass, gunning mix, coated mix, dry vibration material, etc.

- Q: Does anyone know what is the use of waste refractory materials?

- 1.Waste refractory bricks can be reused to make the refractory bricks after being crushed by crusher, but the price is not very high. The purchasing price of refractory plant is ?60/ton. Because the refractory material has been calcinated for two times, it becomes easier to make bricks expansion coefficient with waste refractory bricks, but too much is inadvisable. If too much, the refractory materials would have a bad combination, which will give rise to loose bricks and incomplete corners. Nowadays, ordinary refractory plants would purchase waste refractory bricks to produce bricks, but better plants wouldn’t do this.

- Q: What is the the best matching ratio of refractory cement?

- The best matching ratio of refractory cement is 30%. Refractory cement is also known as aluminate cement. Aluminate cement takes bauxite and limestone as raw materials, alumina content of about 50% as the clinker. And it is a hydraulic cementing material made by grinding. Refractory cement is also known as aluminate cement. Aluminate cement is often yellow or brown or gray. The main mineral of aluminate cement is mono calcium aluminate (CaO · Al2O3, abbreviated CA) and other aluminates, and a small amount of dicalcium silicate (2CaO · SiO2), etc. It is a special cement. I hope my answer will be helpful to you.

- Q: What's the fire resistance rating of the exterior fire?retardant?coating?

- Exterior thick fire-resistant coating for steel structure can reach the first level of fire resistance, thin fire-resistant coating for steel structure can be fire-resistant for three hours, and ultra-thin fire-resistant coating for steel structure can just be within the second level of fire resistance.

- Q: How to choose the material of refractory?

- Long using temperature of aluminum oxide fiber is 1400 ℃, containing chromium aluminum silicate fiber, quartz, high purity aluminum silicate fiber, long-term use of temperature is 1000-1200 ℃ has aluminum silicate refractory fiber according to different raw materials, advanced refractory fiber (such as alumina. Commonly used vitreous aluminum silicate refractory fibre is amorphous, zirconium oxide refractory fibre) using temperature is 1700 ℃ view as >and the best temperature is 1300 ℃. Crystalline refractory fiber are polycrystalline mullite fiber, including ordinary aluminum silicate fiber, alumina and graphite refractory fiber, etc. The use of common refractory fiber temperature is 1150 ℃;>

Send your message to us

Raw Materials for Refractory - Fused Silica Powder 200mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords