Fully Automatic Chemical Tin Can Seam Welder Welding Making Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

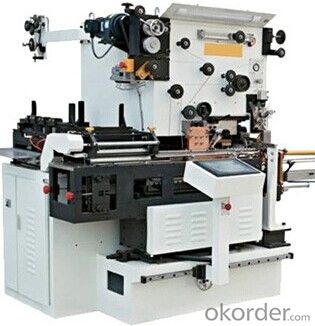

Fully Automatic Chemical Tin Can Seam Welder Welding Making Machine Usage and Applications

Type:Packaging Line

Condition:New

Application:Chemical, Machinery & Hardware

Packaging Type:Cans

Packaging Material:Metal

Automatic Grade:Automatic

Driven Type:Electric

Voltage:380V

Power:40KW

Place of Origin:Zhejiang, China (Mainland)

Certification:CE

After-sales Service Provided:Engineers available to service machinery overseas

Fully Automatic Chemical Tin Can Seam Welder Welding Making Machine Main TechnicalParameters

1.Fully Automatic System

2.VVVF Device

3.High Speed

4.Fault Self-analysis

Name | Automatic Tin Can Seam Welding Machine |

Model | FH18-65ZD |

Usage | It's used for tin can body automatic seam welding |

Production Capacity | 40-100 cans/min |

Welding Speed | 6-26m/min |

Overlap | 0.4mm 0.6mm |

Cooper Wire | Ø1.38 Ø1.5mm |

| Suitable Can Diameter | Ø65-180mm |

| Suitable Can Height | H60-280 |

| Suitable Tinplate Thickness | 0.2-0.35mm |

| Compressed Air Consumption | 600L/min |

| Compressed Air Pressure | 0.5-0.7Mpa |

| Cooling Water | ≤20°C, 0.4-0.5Mpa, 10L/min |

| Power | 380V, 50Hz, 40KW |

| Dimension | 1750*1100*1800mm |

| Weight | 1800KG |

- Q: The role of food packaging machinery

- (8) can promote the development of packaging machinery related industry is a comprehensive science which is related to many subjects, materials, process and equipment, electronics, electrical appliances, automatic control and other related disciplines, requires the simultaneous and coordinated development, the overall performance of any discipline problems will affect the packaging machinery. Therefore, the development of packaging machinery will effectively promote the progress of related disciplines. In addition, in order to meet the needs of high-speed packaging machinery packaging, the relevant front and rear processes are bound to adapt, and also promote the simultaneous development of related processes.Fig. 3 is a flow chart of liquid filling. With empty bottles of boxes stacked on pallets, by the conveyor belt to depalletizers, will remove the tray one by one, the box with the conveyor belt to the machine, remove the empty bottles from the box, empty by the conveying belt to the washing machine, after cleaning, and transported to the packing machine next to filled with beverage bottles into them. The empty bottles removed from the unloading machine are sent into the bottle washing machine by another conveyor belt for disinfection and cleaning. They are tested by the bottle inspection machine and conform to the cleaning standard and then enter the filling machine and capping machine. The beverage is bottled from a filling machine. Packed beverage bottle capping machine with the sealed and transported to the labeling machine labeling, (see pictures) with various beverage bottle filling line of the process is similar. But because of the different nature of beverage, the filling machine and capping machine are also different.

- Q: Predecessors please point out: what is the future of packaging machinery industry?

- China's packaging machinery and equipment manufacturing enterprises should seize this opportunity.The overall upgrading of packaging machinery equipment is the general trend of the development of packaging machinery in China and the world. The main features of the renewal is: a large number of transplanted with civilian and military industries all modern high precision technology and electronic technology, microelectronic technology, edge technology, fuzzy technology, accelerate the further improve the reliability, safety, no work of the level of automation of packaging machinery and equipment and production line. Intelligence will move into the field of packaging machinery, equipment and production lines.

- Q: What are the main plastic forming processes?

- The main equipment used for molding compression is to press and mold. The most used hydraulic press is self support hydraulic press. The tonnage varies from tens to hundreds of tons. There is a lower press and an upper press. The die used for compression molding is called pressing die. It is divided into three kinds: overflow mould, half overflow mould, no overflow mold.The main advantage of compression molding is that it can be molded into larger flat products and can be produced in large quantities. Its disadvantage is long production cycle and low efficiency.2. lamination forming. A method of combining two or more layers of material of the same or different material by heating and pressurizing with or without a binder.A layer of floating hot pressing plate is arranged between the movable plate and the fixed plate of the press.The reinforcing materials used in laminated forming are cotton cloth, glass cloth, paper and asbestos cloth. The resins are phenolic, epoxy, unsaturated polyester, and some thermoplastic resins.

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is suggested that displacement or velocity should be detected on the transport path of the membrane. Is a more reliable control signal. Of course, you can also detect the angular speed of the recovery drum, such as a code dial and other simple institutions.

- Q: Working principle of packing machine

- The working principle of the packing machine is simple. The packing material is first installed on the packing machine and installed

- Q: Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;But to use the hot pressing machine there is to do bakelite mold. Our company specializing in the production of blister, in addition to help customers hot packaging, directly to the finished products to customers

- Q: What is the working principle of the pillow packing machine?

- Some packaging machinery manufacturers, many varieties of products, in the purchase of packaging machines, I hope a device can pack all their own varieties

- Q: What is a packaging machine?

- Packaging machinery refers to the machinery that can complete all or part of the product and commodity packaging process. The packaging process includes filling, wrapping, sealing and other main processes

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- Graphic symbols for packaging and storageGB/T 5009.60. Analytical method for hygienic standard of polyethylene, polystyrene and polypropylene moldings for food packaging

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- (especially the telephone communication, stop talking no worries) I think you should understand the specific situation, your target customers first, for example: mechanical models currently in use and the time of purchase, production efficiency, what will be improved after the replacement, can recover the cost of even a few years, these are all what you should do in advance homework.

Send your message to us

Fully Automatic Chemical Tin Can Seam Welder Welding Making Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords