FRP Roofing Sheet Making Machine/Production Line on Sale Automatically

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 25 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Roofing Sheet Making Machine/Production Line on Sale Automatically

Product Description:

Our standard FRP lighting sheet making machine can make high quality FRP corrugated roofing sheets

continuously.It is used in Industrial plants, warehouses, stadiums, shelters, gardens, agricultural greenhouses,

corridors and canopies.Animal and plant greenhouse roofing.Industrial and civil building roofs and walls day lighting,

such as factory building day lighting band, the hotel, gymnasium,swimming hall, parking lot and so on.

Product Features:

1. Double-layer layout structure, lower the requirement on length of plant.

2. Impregnation platform have multi-line independent temperature control, temperature control is more

precise,able to adapt the changing of ambient temperature,speed of impregnation is fast, speed of production is

improved effectively.

3. Easy operation based on PLC intellectual control system. Computer control, the production task and

equipment operatin data is faster and intuitional. Only short-term training can make operators complete production

independently.

4. Unique temperature control chamber and temperature control arithmetic makes oven heating fast, temperature

control precise,Which improve the quality of products, reduce energy consumption and shorten the preparing time

effectively.This way makes sheets curing better.

Product Parameter:

Name | FRP Roofing Sheet Making Machine/Production Line on Sale Automatically |

Brand | CMAX |

Weight | 8-12T |

Dimension(L*W*H) | Machine Model |

Power | 30KW |

Voltage | 220V |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Film |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Hebei, China (Mainland) |

Color | Customized |

Warranty | 2 Years |

Time of Delivery | 30-45 days |

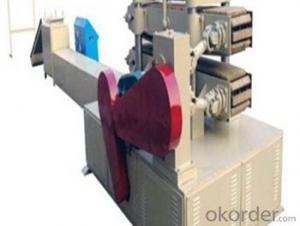

Product Pictures:

Our Services:

1. Guarantee for 2 years excluding wire and electrical parts. Extra fee is paid if out of date.Any damage to the

machine caused by improper use will be charged.

2. The equipment is fully test before delivery.

3. Free installation, training and commissioning on site to help the operators operate as soon as possible.

4. We will provide wear and electrical parts at an agency price when you need replacement.

FAQ:

Q: Why we are your best choice?

A: We have direct factory and many years of export experience, and offer the best price with high

quality product, timely delivery, also have good after-sales service, therefore with good reputation on

boards and with many clients have good long-term business relationship.

Q: Are you trading company or manufacturer ?

A: We are trading company and we have direct factory. Certainly if you need other special product, we

will do our best to help you, so we can build a long-term business relationship.

Q: Can I order the product with special size?

A: Of course you can, also we will produce the products according to your detail requests.

- Q: Who knows Guangdong province processed waste plastic particles Factory where. Thank you

- Yes, they do more, and each place has a different salary.

- Q: Plastic blank in the gear hobbing machine processing, hob and workpiece is not to heat, then plastic is not easy to stick on the machine body.Just want to know the plastic gear processing technology is how, and ordinary steel gear processing technology difference where?.The more detailed, the better. Thank you

- This problem, we have the right to speak, first of all, the plastic material relative to steel are quite soft, so the heating problem, processing on hobbing machine, the heat can be ignored, and, in the gear processing machine will have cooling facilities, to cool the workpiece. So this question, Louzhu worry too much.Also, plastic gears, casting molding, but also useful blank after cutting and forming, and this steel and gear is no big process difference......

- Q: What are the processes and machines used in the manufacture of plastic products?,

- Processing methods are: injection molding, extrusion, blow molding, blister and so on. Injection molding can be used to produce more complex shapes, such as TV housings. It is the plastic particles in the pre heating tube, and then through the screw under pressure, the melting of raw materials into the mold, cooling molding, the product has been made. Is prepared by continuous extrusion screw drive, which in the feed pipe (commonly known as the barrel) heating plasticization, and then squeeze the stereotypes in the mold, the desired shape, such as plastic buckle, pipes etc.. Blow molding and extrusion are somewhat similar, except that they are placed in compressed air to obtain shapes, such as plastic films, plastic bottles, etc.. Blister is relatively simple, it first made of plastic sheets, baking oven, and then placed in the mold, through the negative pressure to the sheet and mold close to the shape. The price of the equipment varies greatly according to the model and specifications, so it can be checked directly to the manufacturer.

- Q: Where do engineering plastics processing best?

- Organic glass rods and plates, PTFE rod material, nylon rod, PVC sheet and other mechanical processing performance is good.

- Q: The main plastic of plastic products

- Polyethylene plastics (Polyethylene) are polymers of ethylene monomers. The raw material for production is oil, coke oven gas or alcohol. Industrial production of polyethylene usually by ethanol dehydration, acetylene catalytic hydrogenation or high temperature cracking. Its commodity name is abbreviated as "B plastic"; the English abbreviation is "PE". Because the density of polyethylene is different, it is divided into low-density polyethylene.[PE (L)], medium density polyethylene [PE (M)] and high density polyethylene [PE (H)].The molecular formula of polyethylene is: (- CH2, CH2 -) n. It is linear in geometry and theoretically has no branched chain and is prone to crystallization. Usually the polyethylene molecule is composed of crystalline and amorphous state in high elastic interlaced region; crystalline polyethylene plastic gives high hardness, strength, chemical stability; amorphous region with polyethylene plastic higher flexibility, toughness, transparency etc.. In fact, polyethylene macromolecules are not absolutely free of branched chains. Its crystallinity is different, density is different, physical and mechanical properties are also different.

- Q: I am going to work as a worker in a plastics factory. I wonder if the work inside it is very polluting. Is there any harm to the health?

- Plastic products factory work on the human body will be a number of pollution, direct pollution, there are indirect pollution, but still depends on what material and what post.Plastic products generally include plastic batching, molding, machining, bonding, finishing and assembly. The latter four processes are carried out after the plastic has been molded into products or semi-finished products. It is also called plastic two times processing.Plastics burn easily and produce poisonous gases when they burn. For example, toluene combustion produces a small amount of polystyrene, this substance can cause blindness, vomiting and other symptoms of inhalation, PVC combustion will produce toxic gases, hydrogen chloride in combustion, is a high temperature environment, will lead to plastic decomposition of toxic components, such as benzene etc..In December 31, 2007, the general office of the State Council issued a notice on limiting the production, sale and use of plastic shopping bags, which was called "plastic restriction order" by the masses". The reason is that plastic shopping bags, while providing convenience to consumers, have caused serious waste of energy, resources and environmental pollution due to excessive use and recycling. As we all know, coupled with the large volume of waste plastic foam, garbage recycling channels are not smooth and other reasons, the pollution problems can not be underestimated. But because of the low cost of plastic foam and easy to use, some well-known online shopping shops still continue to use.

- Q: I found that the plastic bags and food bags used in the county town of my work are from abroad. I would like to open a plastic bag processing plant. What kind of machines do I need?. How much is it (cheaper, smaller per day)?. Where does the raw material go in?. The main market for vegetables; small bags for small food. Who will answer in detail?. Thank you

- The width, thickness and color of the machine can be adjustedThe majority of raw materials is the nearest purchase, can from us into the Hebei Ningjin canal Xingtai plastic industrial zone, we will teach you the technology. We have a lot of bags around here, so you can come over and have a look.If you have time, come and visit our factoryHebei Ningjin Fuda machinery

- Q: What kind of equipment do you need for plastic basin processing? How much is it?

- For each plastic products, it is necessary to make a set of molds, so the cost of mold production is also a small amount of expenditure, according to the size and complexity of the product is less than ten thousand or twenty thousand, more than tens of thousands or even hundreds of thousands of. The purchase of equipment should be several more.

- Q: What kind of machinery does a plastic product factory need?

- Processing from waste to products: plastic cleaning machine, plastic crusher and granulator, these three machines processed waste plastics into plastic particles.Then the plastic particles processed into plastic products: mixing machine, film blowing machine, and then add to bag printing film printing machine, the printed plastic bags made in different types of bag making machine, bag making machine, plastic bags of different cold cutbag machine with flat pocket and vest bag, bag making machine only do vest bag. Then, if the garbage bag is a garbage bag with a roll, you must use a winding bag machine, not even roll, one by one according to the maximum width of the bag size cold cutting bag machine.Note: film blowing machine, bag machine, press machine according to the maximum width of your bag to match. The general standard size is: 600mm, 800mm, 1000mm, 1200mm and other models. The bigger the size, the higher the price

- Q: What chemicals should be used in plastic products?

- Several commonly used plastic additivesPlastic additives can be divided into seven categories according to their specific functions: additives for improving processability, such as thermal stabilityA constant agent, lubricant, etc. Additives for improving mechanical properties, such as plasticizers, toughening agents, etc.. The changeAdditives for good surface properties, such as antistatic agents, coupling agents, etc.. Additives to improve optical properties, such asColorant, etc.. Additives to improve aging properties, such as antioxidants, light stabilizers, etc.. The reduction of plasticAn additive such as an extender, a filler, etc.. The specific effect of giving other additives such as foaming agent,Flame retardant and anti mildew agent etc..Additives are meant to be dispersed in the plastic molecular structure without serious impactA chemical structure of plastics that improves its properties or reduces its cost. Addition of additives, energyThe plastic can improve the processing, physical and chemical functions of the base material and increase the physics and chemistry of the base materialCharacteristic。

Send your message to us

FRP Roofing Sheet Making Machine/Production Line on Sale Automatically

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 25 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords