FRP Grating Moulded Machine Manufacture Light Weight with Competitive Price on Sale

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 25 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Grating Moulded Machine Manufacture Light Weight with Competitive Price on Sale

Product Description:

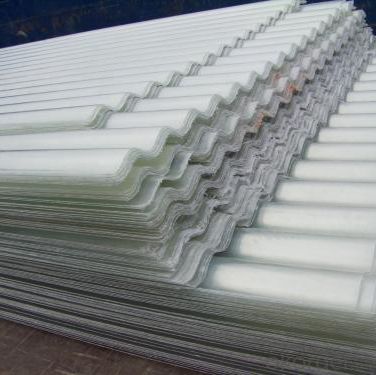

Molded grating is manufactured by laying continuous glass fibres in the mould in the direction of vertical and horizontal, and thoroughly wetted out with resin, layer by layer. When the weaving process is completed, the mould is heated to cure the panel. After curing, the panel is ejected from the mould. The standard panel would have meniscus(concave) top surface.

Product Features:

High anti-fire, High anti-corrosion and anti-aging, High anti-slippery, Light,but high loaded strength, Long service life and maintenance free, Non-conduction or magnetic, Easy installation and rich colors, Various sizes and colors available.

Product Parameter:

Name | FRP Grating Moulded Machine Manufacture Light Weight with Competitive Price on Sale |

Brand | CMAX |

Weight | 2-12T |

Dimension(L*W*H) | Machine Model |

Power | 55KW |

Voltage | 380V 50HZ |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Profile |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Beijing, China (Mainland) |

Color | Selectable |

Warranty | One Year |

Time of Delivery | 30-45 days |

Product Pictures:

Our Services:

1.Do free installation and trial run of microcomputer and equipment, do free training on operators, provide productdesign software until personnel from your honorable company skillfully master it.

2. Responsible for providing advanced domestic production techniques and providing matching techniques and equipment at any time following with development of production technology.

3. Within one year for all occurred troubles of the equipment we serve for you at any time to timely solve the troubles.

4. According to the regulations in the contract timely provide wearing parts in production line and equipment software data.

5. Assist you honorable company to do equipment reform or time changing work, assist you with upgrade work of the production line.

FAQ:

Q: Are you Trading Company or Manufacturing Factory?

A: We are both trading company and manufacturer. We have our own factory, welcome to send your inquiry!

Q: I am interested in your products, could I get sample for free?

A: We can supply a few pieces FREE samples if we have some in stock, and you only need to pay the freight cost by yourself. Welcome to send your inquiry for FREE samples!

Q: How about the Delivery time?

A: 30-45days after receiving the deposit.Welcome to ask for the detailed delivery time according to your order quantity!

Q: How can you guarantee the product quality?

A: We have the quality control system ISO9001:2008, and it's been followed strictly. and each our package worker will be in charge of the final inspection.

- Q: What are the standard tolerances for engineering plastic products machined (e.g. lathes, milling machines)?

- No, look at the drawings, requirements, no note tolerances, drawings should be marked, and if there is no mark, then there is a problem with drawings. Drawing requires that all elements be annotated.

- Q: Plastic POM POM generally used for the production of what plastic products?

- Fire regulating ring, support member, gear, rack, rubber wheel, remote control switch bracket, cam pressure bar, cosmetic container, toy car runner, mobile phone chute

- Q: How much would you like to invest? ThirtyI want to make a wet paper towel and a paper napkin processing factory here. It is specially distributed to hotels, hotels and so onAs the local do not do such packing bag manufacturers, each time from the field of purchase, so I want to do a plastic bag processing plant, so here to consult you. What equipment and materials do you need?

- Film blowing machine, bag making machine, printing machine, raw material, PE granule, printing ink

- Q: Would you please use the collected nylon and plastic film to wash them and machine them?

- I found that the 2 floor is the way out. Do not know their cloud ah.

- Q: Want to buy an injection molding machine to do some plastic products, equipment about how much money ah? What needs to be prepared?

- Tens of thousands of yes, but the quality of the product to do the Department of stability, and later maintenance costs are very expensive, but also trouble, or choose the brand well. Investment step in place.

- Q: How much is the investment? TenCan be processed daily plastic bags, woven bags, garbage bags, clothes bags, there are printed words like that.There is a 300 square foot factory empty home now, best can step can do this ~ ~ wherever he goes high profits? Just try to compare and see what is worth investing in! Trouble you expert pointing! Thanks.

- A full range of equipment from 30 thousand to more than ten thousand, depending on your investment situation, large processing plants have millions of!Towel disinfection profit space is very large, a towel in the cost of 1-2 hair, charge 5 cents a piece in some places (according to the local situation), investigate the market well, as long as the rent is not expensive, the development trend of this industry will be the future, and now a kind of tableware disinfection! It will be one of the most profitable industries!

- Q: What chemicals should be used in plastic products?

- Additives mainly in the following categories:OneAntioxidantsAntioxidantUnsaturated double bonds in plastics are absorbed by oxygen atoms, heat and lightCaused by breaking, resulting in free radicals, which cause a chain reaction, so that the molecular chain scission or formation of chain cross-linking,Resulting in lower or weaker strength of plastic products. The function of antioxidants is to delay the oxidation of plasticsBreak down and prolong the life of plastic products. The antioxidants used in the plastics industry can be divided into functions: (One)Inhibitors of oxidative chain reactions, such as alkylphenolAlkylPhenolButyl tolueneButylatedHydroxytolueneAbbreviationBHT) aromatic aminesAromaticAmines) phenyl - -B-Resistant amine(Phenyl-B-Naphthylamine), were of Kun (AlkylQuinoneAlkenyl bisphenol A(AlkyleneBisphenolAlkyl phenol sulfideAlkylPhenolthioetherSalicylic acidBenzene fingerPhenylSalicylateAnd so on) etc.. (

- Q: What sewage treatment equipment should be used for waste plastics processing granules?

- Waste water produced by processing plastic particlesFirst of all, determine the composition of sewage, and then according to the cost, floor space, water quantity, water quality, local effluent indicators, whether the effluent is used to determine the sewage process, and then use the equipmentYou said so simple, I think your sewage composition will not be too complicated, with integrated sewage equipmentA company can provide a three year warranty! Don't be cheap. Environmental protection will only get tighterAfter three months, the water is out of balance

- Q: How do we calculate the cost?

- There is, HDPE, LDPE, PP membrane is not clear, PET, PVC bottles are not clear, and so on.When the quality is not up to standard, or the production is low, or the production rate is low, I don't know what to do next. It is not easy to ask for advice, but some of them are still conservative and ask for advice.The above situation is often encountered by the company friends ask questions, of course, vary from person to person, can not be generalized. However, there are still some representativeness. In view of the above problems, we put forward some suggestions for reference only, and we welcome colleagues to discuss together, to help the new line of friends, that is, our future counterparts better development.

- Q: Where are home plastic products, plastic products for daily use, plastic products processing, plastic products, mold

- You are looking for people to give you the processing mold, is it, then you go to the hook online to find ah, above doing this factory a lot

Send your message to us

FRP Grating Moulded Machine Manufacture Light Weight with Competitive Price on Sale

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 25 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches