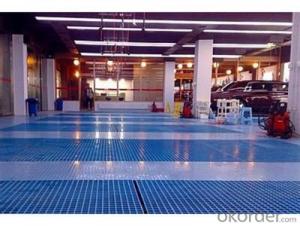

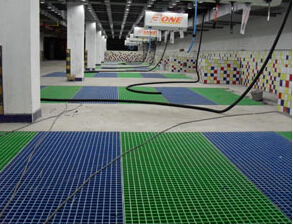

FRP Pultrusion Profiles for Carwash Floor New Style

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of FRP Grating for Carwash Floor:

FRP grating for carwash floor is one kind of glass fiber reinforced plastic (FRP) by using glass fiber for reinforcement, unsaturated polyester resin as matrix, through special processing and become a kind of plate material, with lots of blank space in hebei leading production of glass FRP grasting can be used as a structural material, used for the floor of the corrosion environment, trench cover, platform, ship deck, stair, catwalks, etc.

FRP grating by glass fiber braiding, resin pouring the whole moulding, production with many rules of distribution of rectangle, square space of glass FRP grating plate, with two-way same-sex mechanics characteristics. FRP grating can be widely used in petroleum, chemical industry electronic, electric power, paper, printing and dyeing, electroplating, sewage treatment and other industries, Marine exploration work platforms, equipment platforms, drilling platform, walkway, etc., FRP grating is the ideal product in corrosive environment, at the same time can also be applied to civil construction facilities.

Due to our FRP grating can bear the presence of corrosive liquid, gas, metal corrosion rapidly in these areas, although the anti-corrosion layer and other measures, but for the components of the corrosion is still surprisingly, not only cause bad production environment, and affect production safety, FRP grating sometimes have to stop production maintenance, in the use of FRP grating as structural materials in these regions can have very good effect, it has a long service life, low cost, safe and reliable, no maintenance, and beautiful and easy, and a series of advantages. Of such products in the United States has used more than 30 years, the use, production sales of FRP grating has been standardization, seriation, commercialization, dosage is considerable. , the Middle East oil field in the gulf of reconstruction, the expert argumentation, and think that the use of FRP grating is the most economic and reasonable material, and therefore are a lot of use. In Asia, Singapore and other regions are also using FRP grating.

FRP grating performance characteristics are as follows:

Corrosion resistant

FRP grating has very excellent acid-proof, alkali resistance, resistance to organic solvents and salt, and many other gas and liquid medium corrosion performance, has the incomparable superiority in the field of anti-corrosion. According to the practical application requirements, can choose to use economically o-type, between benzene, vinyl resin base material.

Light weight, high strength, and is convenient for cutting, installation

Because it is by the resin and glass fiber composite, FRP grating density is not more than 2 kg each smaller CDM, is only a quarter of the steel, aluminum two-thirds. 10 times the strength of rigid polyvinyl chloride (PVC), absolute strength more than aluminum and the level of the ordinary steel. Its light weight, can greatly reduce the foundation support, thus reducing the material cost of the project. Its cutting easy installation, without hot and large-scale lifting equipment, only a small amount of manual and electric tools, makes the installation costs are greatly reduced.

Resistance to aging

In theory, the FRP grating service life of over 50 years.

Flame retardant

Ordinary FRP grating flame propagation rate (ASTM E - 84) is not more than 25; Advanced flame retardant vinyl grille the flame propagation rate of no more than 10. Oxygen index is not less than 28 (GB 8924).

Security of FRP Grating

FRP Grating has excellent electrical insulation, 10 kv voltage without breakdown; Without electricity, magnetic available in sensitive to magnetic devices; Glass fiber reinforced plastic FRP grating special structure also has the characteristics such as non-slip, anti-fatigue.

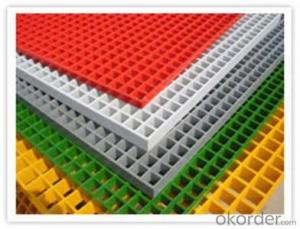

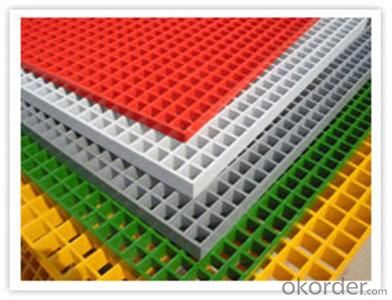

FRP Grating Color

Colors can be arbitrary choice. Can according to customer request custom color, improve the environment in the workplace. General FRP gratings are: yellow, black, grey, green, blue, red and transparent or translucent, etc. In use process can use a single color, also can match.

FRP Grating Can design a strong

Size flexible, convenient and cutting, size stability.

- Q: Are FRP pultrusion profiles resistant to alkaline substances?

- FRP pultrusion profiles are known for their general resistance to alkaline substances. By using fiberglass reinforced polymer (FRP) in pultruded profiles, they acquire excellent resistance against a wide range of chemicals, including alkaline substances. The manufacturing process typically involves using a thermosetting polymer, such as polyester or vinyl ester, as the resin. This choice of resin ensures high resistance to alkaline solutions. Additionally, the fiberglass reinforcement adds strength and durability to the profiles, making them highly resistant to corrosion and degradation caused by alkaline substances. However, it is important to note that the specific resistance of FRP pultrusion profiles to alkaline substances may vary depending on the resin formulation and manufacturing process used. Therefore, it is advisable to consult the manufacturer or supplier to confirm that the profiles meet the specific resistance requirements for alkaline environments.

- Q: Can FRP pultrusion profiles be used in the production of electrical cabinets?

- FRP pultrusion profiles are certainly viable for incorporating into the manufacturing process of electrical cabinets. Their exceptional electrical insulating characteristics render them a fitting option for applications involving the creation of electrical cabinets. These profiles are non-conductive, thus granting insulation and safeguarding against electrical currents, ensuring the security of the electrical components encased within the cabinet. Furthermore, FRP pultrusion profiles boast a high strength-to-weight ratio, resistance to corrosion, and durability, making them a dependable choice for enduring electrical cabinets in diverse settings.

- Q: Are FRP pultrusion profiles resistant to chemicals used in semiconductor manufacturing?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are generally resistant to the chemicals used in semiconductor manufacturing. FRP is known for its excellent chemical resistance, making it a suitable material for various industrial applications, including the semiconductor industry. The composite structure of FRP, consisting of a reinforced fiber matrix embedded in a polymer resin, provides resistance to a wide range of chemicals, including acids, alkalis, solvents, and other aggressive substances commonly used in semiconductor manufacturing processes. This resistance ensures that FRP pultrusion profiles can withstand exposure to these chemicals without significant degradation or corrosion, making them a reliable choice for use in semiconductor manufacturing environments. However, it is always advisable to consult the specific chemical resistance data provided by the manufacturer to ensure compatibility with the exact chemicals and concentrations used in a particular semiconductor manufacturing process.

- Q: How do FRP pultrusion profiles perform in electrical grounding systems?

- FRP (Fiber Reinforced Polymer) pultrusion profiles have shown promising performance in electrical grounding systems. These profiles are made of a combination of fibers, such as glass or carbon, and a polymer resin matrix, which provides high strength, durability, and corrosion resistance. One of the key advantages of FRP pultrusion profiles in electrical grounding systems is their excellent electrical insulation properties. Unlike metals, which conduct electricity, FRP profiles have a very high resistance to electrical current, making them ideal for applications where electrical isolation is crucial. This property helps prevent the risk of electrical shock hazards and reduces the potential for short circuits. Additionally, FRP pultrusion profiles offer high mechanical strength while being lightweight. This makes them easy to handle and install, reducing labor costs and time. The profiles are also resistant to UV radiation, chemicals, and moisture, ensuring long-term performance and durability in various environmental conditions. Another benefit of FRP pultrusion profiles is their resistance to corrosion. Unlike metals, which can rust and deteriorate over time, FRP profiles are immune to corrosion, making them ideal for use in harsh or corrosive environments. This corrosion resistance ensures the longevity and reliability of the electrical grounding system. Furthermore, FRP pultrusion profiles are non-magnetic, which is advantageous in applications where magnetic interference needs to be minimized or eliminated. This characteristic prevents any interference with sensitive electrical equipment and ensures accurate electrical measurements. Overall, FRP pultrusion profiles offer a range of advantages in electrical grounding systems. Their excellent electrical insulation properties, high mechanical strength, corrosion resistance, lightweight nature, and non-magnetic characteristics make them a reliable and efficient choice for ensuring safe and reliable electrical grounding.

- Q: Are FRP pultrusion profiles resistant to wear or abrasion?

- FRP pultrusion profiles exhibit exceptional durability against wear and abrasion due to the integration of reinforcing fibers, predominantly glass or carbon, and a plastic resin matrix. This combination results in a highly robust material that can endure rigorous utilization. Moreover, the pultrusion process guarantees a uniform composition, with fibers uniformly dispersed throughout the profile, thereby augmenting its resistance to wear and abrasion. Furthermore, FRP pultrusion profiles can be customized with specific additives or surface treatments to further heighten their ability to withstand wear and abrasion, rendering them suitable for diverse applications across industries such as construction, transportation, and marine.

- Q: Can FRP pultrusion profiles be used in agricultural applications?

- Yes, FRP pultrusion profiles can be used in agricultural applications. These profiles offer several advantages such as high strength, corrosion resistance, and durability, making them suitable for various agricultural structures and equipment. They can be used for applications like greenhouse structures, livestock housing, irrigation systems, and fencing, among others. Additionally, FRP profiles are lightweight and easy to install, making them a cost-effective choice for agricultural applications.

- Q: Can FRP pultrusion profiles be used in the construction of chemical storage tanks?

- FRP pultrusion profiles have the capability to be utilized in the construction of chemical storage tanks. Their exceptional resistance to corrosion is well-known, making them an optimal choice for storing a wide array of chemicals. Pultrusion profiles, created by pulling fiber reinforcements through a resin bath and then through a heated die, possess a high strength-to-weight ratio, dimensional stability, and durability. Most chemicals do not cause a reaction with FRP pultrusion profiles, and they can withstand harsh environments, including exposure to corrosive substances. The profiles have a low permeability, which prevents chemicals from seeping through the tank walls. Moreover, FRP profiles can be customized to meet specific requirements, enabling the construction of tanks in various shapes and sizes. In addition, FRP pultrusion profiles offer other benefits, such as easy installation, reduced maintenance, and a long service life. Being lightweight simplifies transportation and installation processes. The low maintenance requirements of FRP tanks contribute to minimizing downtime and reducing overall costs. With appropriate design and construction, FRP pultrusion profiles can provide reliable and long-lasting solutions for chemical storage tank applications.

- Q: Can FRP pultrusion profiles be used in the telecommunications and data communication industry?

- Indeed, the telecommunications and data communication industry can utilize FRP (Fiber Reinforced Plastic) pultrusion profiles. These profiles possess numerous advantages that render them appropriate for incorporation in this particular sector. First and foremost, FRP pultrusion profiles exhibit exceptional electrical insulation properties, rendering them perfect for applications in the telecommunications and data communication industry where minimizing electrical conductivity is imperative. FRP profiles do not conduct electricity, thereby ensuring the absence of interference or grounding issues that could potentially disrupt data transmission. Secondly, FRP pultrusion profiles are both lightweight and robust, resulting in a high strength-to-weight ratio. This characteristic makes them well-suited for the construction of communication towers, antenna supports, and satellite dish mountings. In these applications, the profiles must withstand environmental stresses such as wind loads. Moreover, FRP profiles exhibit outstanding corrosion resistance, a crucial attribute in the telecommunications and data communication industry where equipment is frequently exposed to harsh outdoor environments. Unlike traditional materials like steel or aluminum, FRP profiles do not rust or corrode, thereby guaranteeing the longevity and reliability of the infrastructure. Furthermore, FRP profiles can be easily customized and manufactured in various shapes and sizes to meet the precise requirements of telecommunications and data communication applications. This flexibility enables the design and construction of intricate structures capable of accommodating different equipment and technologies. In summary, FRP pultrusion profiles provide a multitude of advantages that render them highly suitable for application in the telecommunications and data communication industry. Their electrical insulation properties, lightweight yet strong nature, corrosion resistance, and design flexibility make them a dependable choice for supporting infrastructure in this sector.

- Q: Can FRP pultrusion profiles be used in the construction of playground equipment?

- Yes, FRP pultrusion profiles can be used in the construction of playground equipment. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength-to-weight ratio, durability, and resistance to corrosion and weathering. These qualities make them suitable for various applications, including playground equipment, where safety and longevity are important factors. FRP pultrusion profiles can be used to construct slides, climbing structures, handrails, and other components of playground equipment, providing a safe and reliable solution for recreational areas.

- Q: Can FRP pultrusion profiles be used in the construction of theme park rides?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of theme park rides. FRP pultrusion profiles offer several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are lightweight yet strong, making them ideal for constructing ride structures that need to withstand dynamic loads and forces. Their high strength-to-weight ratio allows for the creation of large, complex structures that can support the weight of riders and withstand the forces generated during operation. Additionally, FRP pultrusion profiles are corrosion-resistant, which is crucial for theme park rides that are often exposed to outdoor environments, including moisture, chemicals, and UV radiation. This corrosion resistance ensures that the ride structures remain durable and safe over their lifespan, reducing the need for costly maintenance and repairs. Another advantage of FRP pultrusion profiles is their design flexibility. They can be easily molded into various shapes and sizes to meet the specific requirements of theme park ride designs. This versatility allows for the creation of unique and visually appealing ride structures that enhance the overall experience for park visitors. Furthermore, FRP pultrusion profiles offer excellent electrical insulation properties, which can be essential for rides that involve electrical components or systems. This insulation helps to minimize the risk of electrical hazards and ensures the safety of riders and operators. In conclusion, FRP pultrusion profiles are well-suited for the construction of theme park rides due to their lightweight, high strength, corrosion resistance, design flexibility, and electrical insulation properties. These profiles can contribute to the development of safe, durable, and visually appealing ride structures that enhance the enjoyment and excitement of theme park visitors.

Send your message to us

FRP Pultrusion Profiles for Carwash Floor New Style

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords