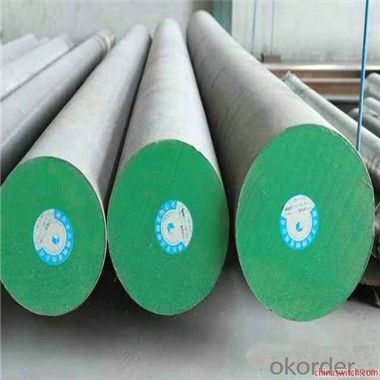

Forged Steel Round Bar SAE8620 /C45 /42CrMo4

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Forged Steel Round Bar SAE8620 /C45 /42CrMo4

Specifications

SAE8620,forged steel round bar,size:90mm to 800mm,Rough turned,Normalized,Annealed,

Quenched and Tempered.

Forged steel round bar

Steel grade:

Carbon steel:

Chinese Standard:20#,25#,35#,45#,50#,60#;

Japan Standard:S20C,S25C,S35C,S45C,S55C,S60C;

US Standard:AISI1020,AISI1040,AISI1045,AISI1050;

Europe Standard:CK15,C.22,C45,CK45,C60,CK60;C45E;

Alloy Steel:

Chinese Standad:16Mn,20Mn,30Mn2,30Mn5,40Cr,Q345D,Q345E,Q390;42CrMo,

20CrMo,38CrMoAl,40CrNiMo;48CrMo,5CrNiMo;

Janpan Standard:SCM415,SCM420,SCM440,SNCM439,SNCM220; SACM645

USA Standard:SAE4140,SAE4130,SAE9840,SAE4340,AISI4145H,SAE4150,SAE8620,

Europe Standard:42CrMo4,25CrMo4,34CrNiMo6,39CrNiMo3,17NiCrMo6,18CrNiMo7-6,

S355J2G3,ASTM A105,ST52-3,16MnCr5,20MnCr5,16MnCrS5,20MnCrS5,21CrMoV511,

56NiCrMoV7,18NiCrMo5,30CrNiMo8,34NiCrMo16,41CrAlNi7,34CrAlNi7,B7,B16,F11,

F12,F22,F5,F9,51Cr4.

Tool Steel:1.2714,H13,H11,P20,SKD61;

Delivery condition:Forged+Normalized/Annealed+RoughTurned

+Quenched and Tempred;

Also can supply the finish products according the drawings;

Length:3 meters or 4 meters and up or fix length according the actually needs

Size:90mm-800mm

Diameter tolerance:-0/+6mm Black surface -0/+2mm Rough Turned

Steel ingot:EAF+LF+VD;

Also use ESR Process if needed;

Ultrasonic Test:According GB/T6401-91 Class 1,Class 2,Class 3;

And GB/T6402-2008 Class 3,Class 2;

And Sep1921 Class C/c,D/d,E/e, Or ASTM A388 Standards;

Grain Size:Better than 6;

Purity, non-metallic inclusions, mechanical properties, hardness According China or EU

Standard;

Quantity:70000 Tons per year

Including Forged round bar 55000 Tons,

Forged square bars 12000Tons,

Other forgings like forged step shaft,forged hollow bars,forged rollers 3000 Tons;

- Q: Can steel round bars be used in the electronics industry?

- Steel round bars can be used in the electronics industry, but their applications are generally limited. While steel is a strong and durable material, it is not typically utilized in electronic components or circuitry due to its electrical conductivity properties. In the electronics industry, materials with high electrical conductivity, such as copper or aluminum, are usually preferred. These materials allow for efficient transmission of electrical signals and minimize losses. However, steel round bars can find some applications in the electronics industry. They can be used for structural purposes, such as providing support or reinforcement to electronic equipment or enclosures. Steel bars can also be utilized in the manufacturing of various mechanical components, connectors, or fixtures used in electronics assembly. Additionally, steel round bars can be employed in the construction of equipment racks, shelves, or storage systems for electronic devices. Overall, while steel round bars may not be directly involved in the electrical aspects of the electronics industry, they can still serve important functions in terms of structural support and mechanical components.

- Q: How do steel round bars compare to titanium round bars?

- Steel round bars and titanium round bars have distinct properties and are used for different purposes. Steel round bars are known for their high strength, durability, and affordability. They are commonly used in construction, manufacturing, and general engineering applications. On the other hand, titanium round bars are much lighter, have superior corrosion resistance, and exhibit high strength-to-weight ratio. This makes them suitable for aerospace, medical, and marine industries where weight reduction and resistance to harsh environments are crucial. Ultimately, the choice between steel and titanium round bars depends on the specific requirements and desired characteristics for the intended application.

- Q: Can steel round bars be used for making turbine blades?

- No, steel round bars cannot be used for making turbine blades. Turbine blades are subjected to high temperatures, extreme forces, and require high levels of durability and flexibility. Steel round bars do not possess the necessary properties to withstand these conditions. Turbine blades are typically made from materials such as titanium alloys or advanced composites that offer high strength-to-weight ratios, excellent fatigue resistance, and thermal stability. These materials are specifically engineered to withstand the demanding conditions of turbine operations, ensuring efficient and reliable performance.

- Q: How strong are steel round bars compared to other materials?

- Steel round bars, renowned for their exceptional strength and durability, are widely recognized as one of the toughest materials available. In comparison to aluminum, brass, and wood, steel round bars boast a significantly higher tensile strength, referring to their capacity to withstand pulling forces without succumbing to breakage. Moreover, steel round bars are capable of handling higher compressive loads, rendering them highly suitable for applications involving substantial pressure or heavy loads. Not only do steel round bars exhibit remarkable strength, but they also showcase excellent ductility, allowing for easy shaping and bending without any risk of fracture. This remarkable feature grants steel round bars versatility, which explains their extensive utilization in diverse industries such as construction, automotive, manufacturing, and aerospace. While other materials possess their own distinctive properties and applications, steel round bars consistently remain the preferred choice in terms of strength and reliability. Their ability to endure high loads, resist deformation, and maintain structural integrity positions them as a favored option for structural components, shafts, axles, and various other demanding applications.

- Q: How are steel round bars used in the construction of stadiums and sports facilities?

- Steel round bars are widely used in the construction of stadiums and sports facilities due to their strength, durability, and versatility. These bars are typically made from carbon steel and are available in various diameters and lengths to meet the specific needs of each project. One of the primary uses of steel round bars in stadium construction is for the reinforcement of concrete structures. These bars are often embedded within concrete columns, beams, and slabs to enhance their load-bearing capacity and overall structural integrity. The high tensile strength of steel allows it to withstand heavy loads and provide the necessary support for large seating areas, roofs, and other architectural elements. Steel round bars are also used in the construction of stadium roofs and canopies. These structures require a strong and lightweight material that can span long distances without the need for excessive support columns. Steel bars, when properly designed and installed, offer an ideal solution by providing the necessary strength while minimizing the number of support elements, thus allowing for unobstructed views and spacious seating arrangements. Additionally, steel round bars are commonly used in the fabrication of stadium fences, guardrails, and handrails. These components are crucial for ensuring the safety and security of spectators, preventing falls or accidents in elevated areas, and guiding the flow of people within the facility. The high tensile strength of steel provides the necessary resistance against impact, making it an ideal material for these applications. In summary, steel round bars play a crucial role in the construction of stadiums and sports facilities. Their strength, durability, and versatility make them a preferred choice for reinforcing concrete structures, constructing roofs and canopies, and fabricating safety components. By utilizing steel round bars, stadiums can be built to withstand heavy loads, provide unobstructed views, and ensure the safety of spectators, ultimately enhancing the overall experience for sports enthusiasts.

- Q: What is the difference between carbon steel and alloy steel round bars?

- Carbon steel round bars are made primarily of carbon and iron, while alloy steel round bars are made of carbon, iron, and other elements such as chromium, nickel, or manganese. Alloy steel round bars have enhanced properties such as increased strength, hardness, and resistance to corrosion, making them ideal for applications that require higher performance. On the other hand, carbon steel round bars are more affordable and have good machinability, making them suitable for general-purpose use.

- Q: Excuse me and steel disc round what is the difference?

- Main application: Pu wire is mainly used for building reinforced concrete structure for reinforcing bars, and it can also be made of cold drawn steel wire for strapping and so on.

- Q: What is the minimum yield strength of steel round bars?

- The specific grade and type of steel being used can cause the minimum yield strength of steel round bars to vary. However, the majority of steel round bars generally possess a minimum yield strength of 36,000 psi (pounds per square inch) or 250 megapascals (MPa). This minimum yield strength ensures that the steel round bars are strong enough to resist applied loads and avoid deformation or failure. It is worth mentioning that certain applications may demand steel round bars with higher yield strengths to fulfill particular performance criteria.

- Q: What are the different types of steel round bar surface treatments?

- Steel round bars can undergo various surface treatments to enhance their appearance, durability, and resistance to corrosion. Some commonly used treatments are: 1. Hot-dip galvanizing: Immerse the steel round bar in molten zinc to create a protective zinc coating, preventing rust and corrosion. Ideal for outdoor applications. 2. Electroplating: Apply a layer of another metal, like chrome or nickel, to the steel round bar. Improves appearance and corrosion resistance. 3. Powder coating: Electrostatically apply a dry powder to the surface, then cure it under heat. Creates a hard, durable, and attractive finish resistant to chipping, scratching, and fading. 4. Passivation: Chemically remove impurities from the surface, leaving a clean and corrosion-resistant layer. Commonly used for enhancing rust resistance in stainless steel bars. 5. Black oxide coating: Form a thin layer of black iron oxide on the surface. Provides mild corrosion resistance and a sleek black appearance. 6. Shot blasting: Propel abrasive materials at high speeds onto the surface to remove impurities or scale. Improves appearance and promotes better coating adhesion. 7. Acid pickling: Immerse the bar in an acid bath to remove scale and impurities, leaving a clean surface free from contaminants. These treatments are just a few examples of what can be done to steel round bars. The choice depends on factors such as the bar's intended use, desired appearance, and required corrosion resistance level.

- Q: What are the typical dimensions of a steel round bar?

- The typical dimensions of a steel round bar can vary depending on the specific application and industry requirements. However, in general, steel round bars are commonly available in diameter sizes ranging from 1/4 inch to 24 inches. These dimensions are often measured in increments of 1/8 inch or 1/4 inch. The length of a steel round bar is typically standardized at 20 feet, although shorter lengths may also be available. It is important to note that these dimensions can vary significantly depending on the specific grade and type of steel being used, as well as the manufacturing process. Therefore, it is essential to consult the appropriate industry standards or consult with a supplier to determine the exact dimensions needed for a particular project.

Send your message to us

Forged Steel Round Bar SAE8620 /C45 /42CrMo4

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords