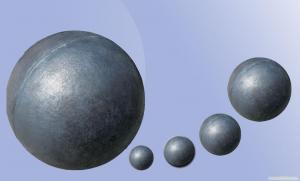

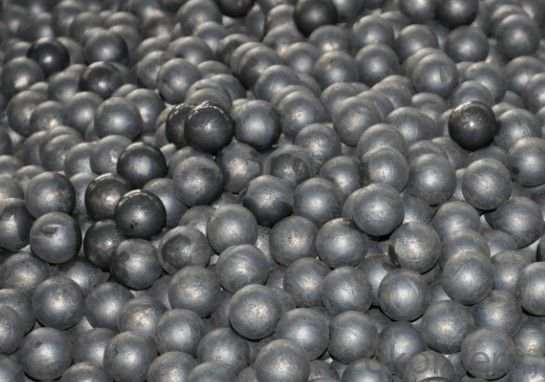

Forged and Casting Grinding Steel Ball with High Hardness Made in China for Mineral Processing and Cement Plan

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Forged and Casting Grinding Steel Ball with High Hardness Made in China for Mineral Processing

and Cement Plant:

1. High hardness

2. Good wear resistance

3. High toughness

4. No mal-roundness

Applied Fields of Specifications of Forged and Casting Grinding Steel Ball with High Hardness Made in China for

Mineral Processing and Cement Plant:

1. Mines

2. Cement Plants

3. Chemical Industries

4. Power Plant

Type and Chemical Composition of Specifications of Forged and Casting Grinding Steel Ball with High Hardness

Made in China for Mineral Processing and Cement Plant:

Name

|

Material |

C |

Si |

Cr |

Mn |

S |

P |

CNBM-7 | Cr-22-32% | 2.0-2.8 | ≤1.0 | 22-32 | 0.5-2.0 | ≤0.06 | ≤0.08 |

CNBM -8 | Cr-17-22% | 2.0-2.8 | ≤1.0 | 17-22 | 0.5-2.0 | ≤0.06 | ≤0.08 |

CNBM -9 | Cr-15-17% | 2.2-3.0 | ≤1.0 | 15-17 | 0.5-2.0 | ≤0.06 | ≤0.08 |

CNBM -10 | Cr-11-14% | 2.2-3.2 | ≤1.0 | 11-14 | 0.5-2.5 | ≤0.06 | ≤0.08 |

CNBM -11 | Cr-5-10% | 2.1-3.2 | ≤1.2 | 5-10 | 0.5-1.5 | ≤0.06 | ≤0.08 |

CNBM -12 | Cr-1.5-3.% | 2.2-3.5 | ≤1.2 | 1.5-3.0 | 0.5-1.5 | ≤0.06 | ≤0.08 |

Physical Property of Specifications of Forged and Casting Grinding Steel Ball with High Hardness Made in China for

Mineral Processing and Cement Plant:

Name

|

Material

|

Impact Test Ak.J/cm |

Endurance Test times (5m) | Hardness (HRC) | |||

Diam25-60mm | Diam70-100mm | ||||||

Quenching | Unquenching | Quenching | Unquench ing | ||||

CNBM -7 | Cr-22-32% | ≥4 | ≥10000 | ≥60 | ≥49 | ≥60 | ≥48 |

CNBM -8 | Cr-17-22% | ≥4 | ≥10000 | ≥60 | ≥49 | ≥60 | ≥48 |

CNBM -9 | Cr-15-17% | ≥4 | ≥10000 | ≥60 | ≥49 | ≥58 | ≥48 |

CNBM -10 | Cr-11-14% | ≥3 | ≥10000 | ≥58 | ≥49 | ≥56 | ≥48 |

CNBM -11 | Cr-5-10% | ≥3 | ≥8000 | - | ≥48 | - | ≥48 |

CNBM -12 | Cr-1.5-3.% | ≥2 | ≥8000 | - | ≥48 | - | ≥45 |

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- General Casting Factory Casting Division will be in your chart marked on shrinkage and processing margin figure (usually with red and green pen) to the patternmaker production of wood or other material mould diagram.

- Q: How to calculate the price of casting parts?

- According to the complexity of the workpiece, material and casting requirements and process yield

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angle

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: Is the cast steel a casting part?

- Cast steel is one of the casting parts that you call. The material is made of carbon steel or alloy steel, stainless steel, etc. the method is cast

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: What is the difference between forging parts and casting parts?

- Forging is in hot state through the metal hammer or press equipment produced by forging parts. A casting is a metal that is liquid and is poured into a cavity of a specified shape and cooled and solidified. It is the forging metal soft pinch molding, and casting the metal into thin cooling solidification.Forged parts are costly and have long production cycles.

- Q: In theory, which is more expensive, forging parts or casting parts?

- It depends on the structure. In theory, the shape of the forging is relatively simple, but the requirement of internal structure is relatively high

- Q: What kind of flaw detector is better for casting parts?

- If you want to detect internal defects, you can use ultrasonic flaw detector, ray flaw detector can also, but the ray of the safety protection level is too high, not recommended priorityMacro Xu flaw detector answered, such as the magnetic particle inspection machine has the demand can contact us, Baidu "macro Xu flaw detection""

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2000 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | Domestic Market, South Asia, Southern Europe, Northern Europe, Central America |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Balls; Grinding Rods; Grinding Cylpebs. |

| Product Price Range | Average |

Send your message to us

Forged and Casting Grinding Steel Ball with High Hardness Made in China for Mineral Processing and Cement Plan

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords