Floor To Ceiling Aluminium Windows with Color Coated Aluminum Sheet Coil for Ceiling System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Place of Origin: | Brand Name: | |||

| Model Number: | Function: | Feature: | |||

| Ceiling Tile Shape: | Ceiling Tile Type: | Surface Treatment: | |||

| Metal Ceiling Material: | Key word: | Specification: | |||

| Height: | Thickness: | Perforated diameter: | |||

| Color: | MOQ: | Delivery time: | |||

| Packing: | Certificate: |

1) Our clip in aluminum ceiling:

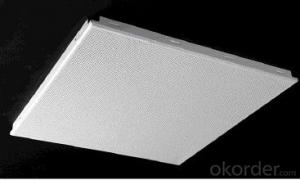

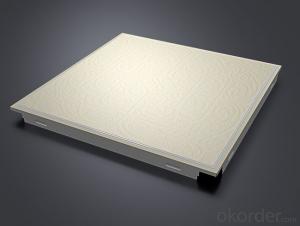

Clip in square ceiling, widest applicable among all type of ceiling with outstanding advantages. Plain or pattern can be selected according to the actual requirement. Clip in system which is concealed, steady structure, flat surface, could be both used as ceiling and wall panel.

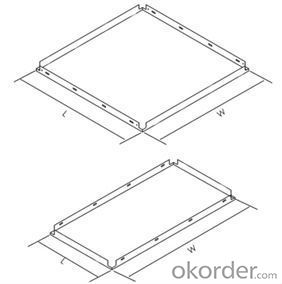

2) Specifications:

| Specification | Thickness | Height | Legend |

| 300×300mm | 0.4-1.0mm | 19mm(short edge) 25mm(High edge) |  |

| 300×450mm | |||

| 300×600mm | |||

| 300×1200mm | |||

| 400×400mm | 0.5-1.2mm | ||

| 500×500mm | |||

| 600×600mm | |||

| 600×1200mm | |||

| Base materials | Aluminum alloy, the grade of aluminum alloy can be selected according to the actual requirements; Besides, galvanized iron and stainless steel material is also available | ||

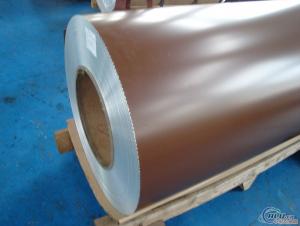

| Surface treatment | Powder coated(ordinary powder, Polyester powder), Paint coated, Film coated | ||

| Type of Surface | Plain plate or perforated plate is selected according to the actual requirements | ||

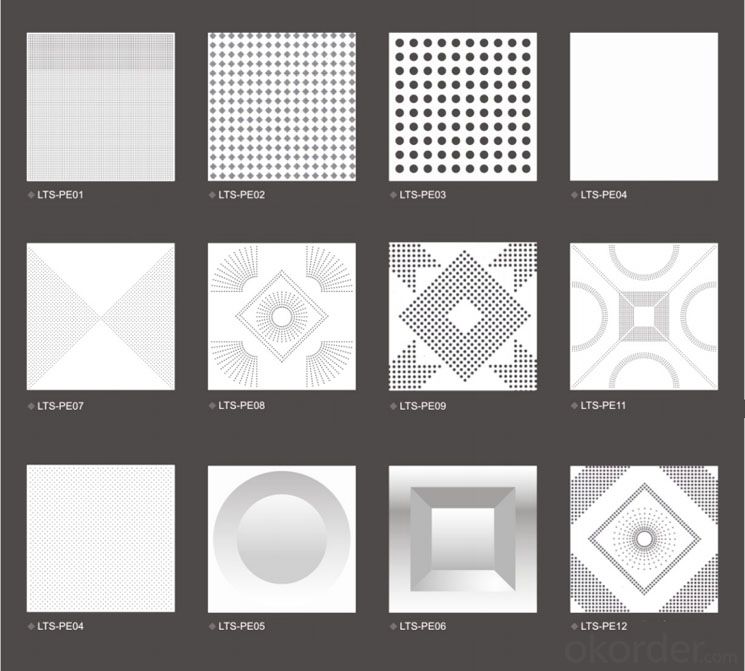

3) perforated pattern:

Perforation is a kind of processing technology for metal ceiling.Ceiling design beautiful patterns according to the arrangement of perforated holes with powerful sound absorbing and isolating effect. Rators possesses over 40 kinds of fixed perforated types, and could be customized according to client's requirements on patterns, sound absorbing to meet the actual situation.

4)Our Packing:

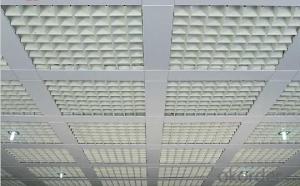

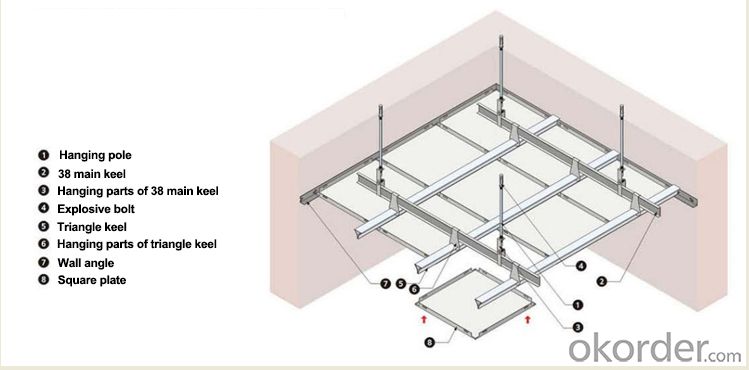

5)Installation Method:

The upper main keel and lower triangle keel are tightly connected with "cross" structure,therefore,it can assure the levelness of whole suspended system with more solid structure.

6)Sample Project:

7)Application:

mainly used in project for big area with soundproof requirements, such as hotels,stores,office building, hospitals,railway stations,metro stations and so on.

8)Certificate:

ISO9001:2008, BV,TUV, Product Quality Certificate.

9)Factory Tour:

- Q: Integrated ceiling aluminum slab plate production process?

- Integrated ceiling aluminum plate production process: Kouban production is a very rigorous process, every link is very strict, so that it can produce qualified aluminum slab products. The first step is the aluminum plate surface treatment, such as film, roller coating, spraying, wood transfer and so on. The second part, aluminum plate scissors. It means that the aluminum roll cut into the required size. Such as 300 * 300 specifications. The third part, press molding. Using different aluminum buckle plate abrasive extrusion. There are two parts: strip and square. Fourth, the packaging. Carton and plastic foam packaging out of the library.

- Q: There are long and rectangular, and square, they are what size?

- Square 300X300 with more, 600X600 is also some, long-shaped 100,150,200 are

- Q: Can the ceiling paint on the ceiling?

- Can not. A long time will fall out

- Q: Aluminum buckle plate aluminum plate wholesale price is how much

- Home and the use of aluminum slab plate thickness is generally 0.6mm and 0.8mm. Because the thickness of the aluminum plate is the best cost-effective, fully able to meet the load strength. If the thickness of thickening, not only a waste of resources, but also increased the consumer's unnecessary economic burden. And even some good brand, due to the use of aluminum material is very good, the thickness of only 0.45mm. Therefore, consumers in the purchase of aluminum plate, can not just judge the quality of sheet metal plate, the need for consumers is clear that the plate material is to determine the quality of aluminum standard plate, good aluminum toughness and strength appropriate, Recycled aluminum is often hard, but tough but poor.

- Q: Figure, 600 * 600 or 300 * 300 aluminum buckle plate can not make such a light groove, the edge is not used to close the edge of the edge? Not much, thanks for the answer!

- Side of the edge is no problem, but the aluminum plate to do this, may not be good-looking, there are two main, one is added after the light of the aluminum plate will be bright light, the second is the same as the aluminum plate will reflect the light Tube or a long time gray, ugly.

- Q: Kitchen, bathroom ceiling with aluminum alloy plate is good or plastic buckle plate good?

- I suggest you use a square aluminum plate, easy to repair later, hardness is also good point, not easy to deformation, the European 8mm with artificial and auxiliary materials together is probably 68 square

- Q: Will the kitchen decoration, ceiling ceiling (aluminum plate) can install chandeliers. Master said that the general are decorated board LED lights. I do not look good. Seek answers.

- Kitchen soot too much, chandelier bad cleaning!

- Q: How to install the kitchen aluminum plate

- General buckle with a dedicated keel, keel for galvanized steel and paint steel, the standard length: 3000MM. The 1, according to the same level of height installed edge collection series. 2, according to the appropriate spacing hoisting light steel keel (38 or 50 keel), the general spacing of 1-1.2 meters, the distance from the provisions of light steel keel distribution. 3, the pre-installed in the buckle keel hanging pieces, together with the buckle keel close to the light steel keel and light steel keel in the vertical direction buckle in the light steel keel below the girdle keel spacing is generally 1 meter, all Bahrain must Adjust the level (in general, the vertical distance between the building and the aluminum plate to be lifted does not exceed 600MM, do not need the middle plus 38 keel or 50 keel, and the use of keel hanging pieces and plug directly connected). 4, the buckle in parallel with the order of parallel buckle in supporting the keel, the buckle board connection with a special keel series connection connection. 5, the board must be installed with gloves, such as accidentally leave fingerprints or stains can be washed with detergent after cleaning can be dry, a good installation process easy to disassemble.

- Q: It is best to explain the method, first thank you all

- Then you first installed clothesets and then install the aluminum plate, but to pay attention to height.

- Q: My house north of the balcony to install curtains, but the above is the aluminum plate, three sides are glass, how to install curtains, or can play the curtains of other practices are also OK, but do not want to use the film.

- There is a high-strength viscosity of the B-combination can stick

Send your message to us

Floor To Ceiling Aluminium Windows with Color Coated Aluminum Sheet Coil for Ceiling System

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords