Flat Black Aluminum Sheets - Continuous Casting Aluminium Strips for Food Cookware AA1060

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Continuous Casting Aluminium Strips for Food Cookware AA1060

Continuous Casting Aluminium Strips for Food Cookware AA1060 are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of Continuous Casting Aluminium Strips for Food Cookware AA1060

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

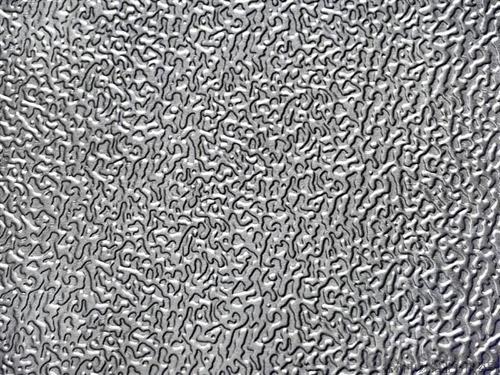

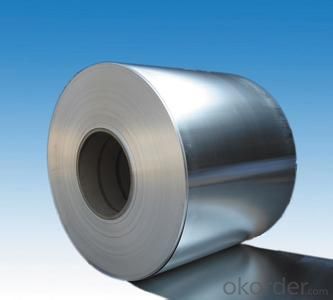

3. Image of Continuous Casting Aluminium Strips for Food Cookware AA1060

4. Product Specification of Continuous Casting Aluminium Strips for Food Cookware AA1060

| Alloy | Temper | Rolling | Thickness | Width |

| AA1060 | F | Hot Rolled | 0.2MM-2MM | 1000MM-1500MM |

5.FAQ of Continuous Casting Aluminium Strips for Food Cookware AA1060

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum sheet withstand heavy loads?

- Yes, aluminum sheet can withstand heavy loads. Aluminum is known for its high strength-to-weight ratio, making it an excellent choice for applications that require durability and load-bearing capabilities. Aluminum sheets are commonly used in industries such as aerospace, automotive, construction, and marine, where heavy loads are involved. Additionally, aluminum's inherent corrosion resistance further enhances its ability to withstand heavy loads over extended periods. However, it is important to consider the specific grade and thickness of the aluminum sheet, as different alloys and thicknesses have varying load capacities.

- Q: What are the various color and pattern options for aluminum sheets?

- <p>Aluminum sheets are available in a wide range of colors and patterns to suit various applications and aesthetic preferences. Colors can include silver, white, black, bronze, and many other shades. Patterns can range from simple matte or gloss finishes to more complex textures like wood grain, stone, and brushed metal effects. Some aluminum sheets also feature anodized finishes for enhanced durability and color vibrancy. Custom colors and patterns can be created through specialized coating processes, allowing for a high level of personalization in design and construction projects.</p>

- Q: What is the density of aluminum plate?

- Pure aluminum plate density: 2.71 alloy aluminum plate density: 2.8 antirust aluminum plate density: 2.73

- Q: Can aluminum sheets be used in food packaging?

- Yes, aluminum sheets can be used in food packaging. Aluminum is a common material choice for food packaging due to its excellent barrier properties, durability, and ability to maintain the freshness and quality of food products. It is also lightweight, recyclable, and resistant to moisture, odors, and UV light.

- Q: Which kind of glue is best for bonding aluminum sheets?

- 502 or universal glue

- Q: This question asks for methods to determine if a building is utilizing high-quality aluminum sheets.

- <p>To determine if a building is using high-quality aluminum sheets, look for the following characteristics: the sheets should have a uniform and smooth surface without visible defects or impurities. Check for a strong and consistent thickness throughout the material. High-quality aluminum is also resistant to corrosion and should not show signs of rust or pitting. Additionally, the sheets should be lightweight yet rigid, indicating a high strength-to-weight ratio. You can also inquire about the manufacturer's specifications and certifications, as reputable suppliers will provide detailed information about the quality and composition of their aluminum sheets.</p>

- Q: Cooks are warned not to use aluminum cookware when preparing acidic foods. Why?

- Plain okorder /... Hope this helps.

- Q: doesn't particularly need to be welding but i need to make an air tight permanent seal around 2 very thin sheets of aluminium (like .02 inches thick) i was thinking .02 inch 5052 aluminum because its the thinnest i can find but am obviously up for suggestions.

- First you need a Tungsten inert gas welder (T.I.G. for short). The second step is to make sure the aluminum is clean. If you just bought it , and it looks clean ; it isn't trust me. Steel and aluminum are totally different in a lot of ways and that is one of them. I'm going to skip the safety instructions and shopping list , under the presumption that you already know the basics. Spray the area to be welded with acetone. rinse with clean water to remove lingering residue. then use a wire brush that has never been used on anything but Aluminum to clean the area. I'd go with a 4043 welding rod , it's a popular choice. Make sure to use clamps so that the 2 pieces of metal are squeezed tightly together with no gaps. (very important) I like to preheat my metal even if it's thin sheets , seems to come out better although it isn't usually called for in specs. side note ; If you have to step away from your work for more than 8 hours , you're going to need to re-prep it since it will have formed a layer of Aluminum oxide by that time.

- Q: Are the aluminum sheets suitable for manufacturing power distribution panels?

- Yes, aluminum sheets are suitable for manufacturing power distribution panels. Aluminum is a lightweight, durable, and corrosion-resistant material that makes it an ideal choice for various industrial applications, including power distribution panels. Aluminum sheets can withstand high electrical currents while effectively dissipating heat, ensuring the safe and efficient distribution of power. Additionally, aluminum is readily available and cost-effective compared to other materials such as copper. Therefore, aluminum sheets are a suitable choice for manufacturing power distribution panels.

- Q: Is aluminum sheet resistant to UV rays?

- Yes, aluminum sheet is resistant to UV rays.

Send your message to us

Flat Black Aluminum Sheets - Continuous Casting Aluminium Strips for Food Cookware AA1060

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords