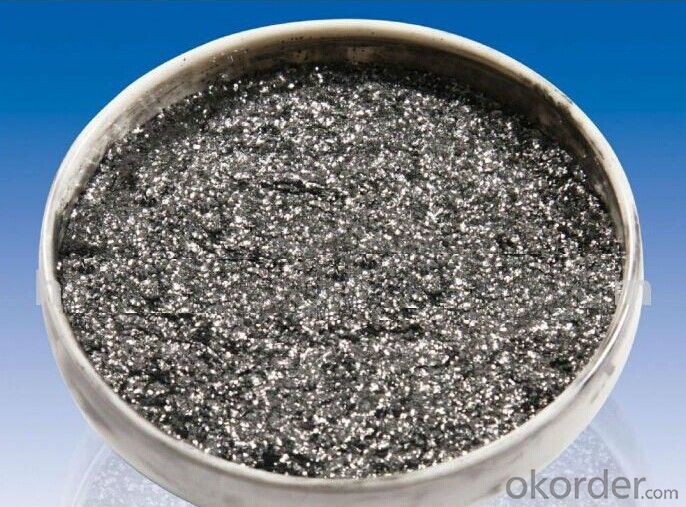

Raw Materials for Refractory:Flake Graphite with Good Quality and Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Flake Graphite With Good Quality And Price

Features

Governmental Company

Good Quality& High Heat-resistance

Competitive Price & Timely delivery

Product Description

1.Types:High-purity graphite,high carbon grahite.

2. Specifications:The particle size ranges from (325mesh-35mesh),

and the carbon content ranges from85 to 99.9%.

PROPERTIES | CNBM-NFG1 | CNBM-NFG2 | CNBM-NFG3 |

Medium Carbon | High Carbon | High Pure | |

Carbon | 85-95% | 96%-99% | 99.9% |

Mesh | 45 μm-500 μm (325mesh-35mesh) | ||

V.M. | ≤4% | ||

Moisture | ≤0.5% | ||

Color | Black Shiny, | ||

Appearance | Flake | ||

Packaging & Shipping

Packaging: 1.25MT jumbo bags or 1MT jumbo bags

Delivery details: according to customers’ requirements

Applications

1.Used as release agent lubricant in the production of chemical industrial catalyzer.

2.Used as high temperature resistance lubricant base material,erosion resistance lubricant base material.

3.Used as powder metallurgy release agent and metal alloy material.

4.Suitable for making graphite refractory bricks.

Company information:

China National Building Materials Group is a stated -owned enterprise in charge of administrative affairs in China buiding materials industry.Established in 1984 CNBM is a large group corporation of building materials with total assets of 25 billion and a total stuff of 30000 CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

- Q: Who knows about roof fireproofing materials?

- At present, only phenolic foam boards can meet requirements. The test temperature can be 2,000 degrees, and there is no molten droplet during the tests and it can maintain integrity. heat conductivity coefficient: 0.03W / (mk), non-combustible, non-toxic, smokeless!

- Q: What's the requirements of fire-fighting criteria of heat insulating material?

- It shouldn't be under than B2 level. Roofing insulation fire rating requirements: the ministry of public security, housing and urban-rural development department issued about printing and distributing the civil building external thermal insulation system and the interim provisions on the exterior wall decorative fireproof prescribed in the notice: roof grassroots adopted duration of fire resistance is the non-combustible component that shouldn't less than 1.00 h's. Its roof insulation materials should not be below B2; Otherwise, the combustion performance of insulating material should not be below the B1 level. The junction of the roof and wall, the insulation layer around the opening part of roof should use the grade A thermal insulation material to set level fire-fighting belt that width is not less than 500 mm.

- Q: what's the classification of fireproof and thermal inuslation matertial?

- 1. thermal insulation material with A class combustion performance. Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite (2) thermal insulation material with B class combustion performance: extruded polystyrene board after special processing (XPS)/ polyurethane after special processing (PU) , phenolic aldehyde, gelatine powder polyphenyl granule. 3,thermal insulation material with B2 class combustion performance: molding polystyrene board(EPS), extruded polystyrene board(XPS), polyurethane (PU), polyethylene (PE),etc. sea capacity module and vitrified micro bead(cooperate with the innovator of vitrified micro bead, Liu Weihua) fireproofing issues have been completely solved.

- Q: Why does refractory need to add coarse firstly and then add fine aggregate?

- Binding agent can wrap particles and improve binding effect.

- Q: What is refractory aggregate?

- Refractory aggregate is fire-resistant product improved with low temperature binder, chemical?compound and normal temperature strength.

- Q: What kind of material is refractory bauxite?

- Refractory bauxite, also known as bauxite alumina or bauxite with high alumina, is the main raw material for the production of high alumina (aluminum content ≥48%, belongs to LAS) refractory.

- Q: What parts of cement kilns are refractories used on?

- In kilns.

- Q: What is shapeless refractory with high performance?

- The popular ones are: Non-cement fine powder bonded castable is a functional refractory castable with nano material introduced.

- Q: What is the the best ratio of mortar in refractory cement?

- Specifical proportions are as following: 42.5R cement is 425 rapid hardening cement. Using the 425 cement to compound the mortar. The reducion of cement will naturally impact the workability of the mortar. The mix design standard of the mortar specifies the minimum amount of cement is not less than 200kg / m3. If it is composite mortar, and the strength and workability can be ensured, it is Ok to use 425 to compound. You can look for instructions of mixing proportion of mortar online as a reference.

- Q: How to distinguish the fire resistant level of construction materials?

- There are 3 conditions for building components to reach fire endurance, namely: Loss of ability to support; loss of integrity; loss of fire insulation function. As long as one condition occurs, fire endurance is reached and the time before it is called fire endurance. 1), loss of ability to support: If the specimen bearing capacity and rigidity reduce, section area shrink, collapses or deformation exceeds specified numerical value because it cannot bear the load of original design under flame or high temperature, it loses the ability to support. 2), loss of integrity: It mainly refers to the thin wall separating component(such as stairs, windows,partitions, ceiling, etc.) burst or partially collapse under flame or high temperature, and penetrating?fracture or opening appears, and the reverse side even burn. For example, when the floor is under flame or at high temperature, the flame spread to the upper room, which indicates that the integrity has been damaged. 3), loss of fire insulation function: It mainly refers to that seperating components loses thermal insulation and excessive heat conduction. In experiment, if the average temperature of component unexposed surface exceeds 140 ℃, or if any spot at the unexposed surface exceed the initial temperature of 180 ℃, the component loses fire insulation function.

Send your message to us

Raw Materials for Refractory:Flake Graphite with Good Quality and Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords