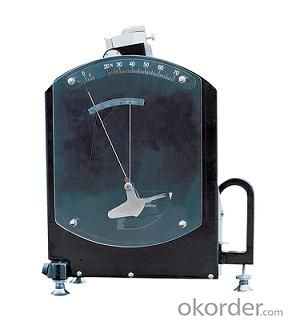

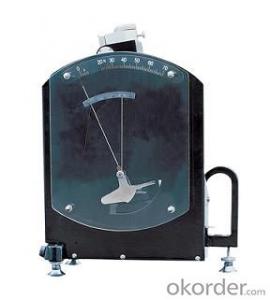

FIBRE BUNDLE STENGTH TESTER

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SPECIFICATIONS

YG011 fiber bundle strength tester is an instrument to check the holdingstrength and elongation at breakage of fiber tufts

APPLICATION

STELOMETER is an instrument to check the holding strength and elongation at breakageof fiber tufts.

Holding strength reading on a graduated scale from 0 to 7 kPa (step0.1kPa), elongation reading on a graduated scale from 0% to 50%.

STANDARDS

Standard | ISO 3060 |

Note: this tester can conform to but not limit to the standards above, formore standards conformance, please contact us.

FEATURES

l Calibrate each stelometer by force measuring andelongation devices that are special designed by our company only, ensurepointer indications (force value and elongation) are match to real value andkeep test result stable and high accuracy;

l Special designed table clamps and pressley clamp (we aresupplier for USTER) can hold fiber tufts effectively, and avoid slipping oraffect test as hold tight;

l Read test values of breaking strength and elongationdirectly from two scales after finishing test;

l After fiber tufts breaks, there is no malfunctionmistakes;

l Test result with high accuracy and with good correlationwith yarn strength.

Standard Configuration of Fiber Bundle Strength Tester:

Thickness of sample holding clamp | 11.8mm |

Thickness of separator | 3.2mm |

Test Range | Breaking Load 20N-70N Elongation 0-50% (3.2mm) |

Applying load speed | 10N/s, adjustable |

Correction Coefficient (approxi.) | 0.9-1.1 |

Environment | Temperature be 20±2°C, Relative humidity be (65±3)%) |

Dimension | 320 x390 x160mm |

Weight | 10kg |

- Q: Axial fan installed directly on the wall exhaust, how to determine its wind pressure?

- At present, for the exhaust ventilation and the like, as long as the appearance of feeling to achieve ventilation effect can be, if it is a high standard of acceptance, it needs to be measured, on the measurement method, you can ask manufacturers to provide.

- Q: What is the reason for the vibration of the fan?

- Fan of the impeller of the dynamic and static balance failed, with the fan after a certain period of time after the impeller uneven wear line caused by poor balance,

- Q: What is the difference between an axial fan and a smoke exhaust fan?

- The Axial fan blades work in much the same way as aircraft wings. However, the latter is the lifting force on the wing and support the weight of the aircraft, while the axial fan is fixed position and the air to move.

- Q: What is the difference between the fan and the compressor?

- Blowers are usually air-cooled, oil-free. Although the blower can be designed for secondary and tertiary compression, but due to low efficiency. Usually single-stage compression, applied to low-voltage applications. Blowers are often used as vacuum pumps and pneumatic conveying.

- Q: What is the difference between an axial fan and a DC fan?

- Fan by the direction of the wind can be divided into axial flow, centrifugal and mixed flow, that is, straight into the straight out, straight into the 90 degrees out, straight into the 45 degrees

- Q: How to reduce fan noise?

- Machine discrete noise (rotating noise): the rotation of the impeller. Especially in high-speed, low load conditions, this noise is particularly prominent. Discrete noise is due to the asymmetry between the blade structure and the blade design test rotation formed by the formation of the circumferential flow of the interaction caused by uneven noise, is generally considered to have the following

- Q: What is the fan D drive?

- Fan impeller cantilever support, pulley in the two bearings outside the V-belt drive;

- Q: How to see the axial fan is good or bad?

- The Axial fans are often used in situations where the flow rate is high and the pressure is low. The axial fan is fixed and moves the air

- Q: What is the working principle of the suction blower?

- Take the fan as an example: observe the fan blade, the blade has an angle. When the blade is rotated, the air is cut, and the side of the blade is expelled from the air, resulting in an increase in the local pressure of the air, an increase in the air density (the power to automatically return to normal pressure)

- Q: Why does the fan start the current?

- Fan is the abbreviation of gas compression and gas transportation machinery in China. Generally speaking, the fans include: ventilators, blowers, wind turbines. Gas compression and gas transport machinery is the conversion of mechanical energy into gas pressure energy and kinetic energy, and the gas transported out of the machinery.

Send your message to us

FIBRE BUNDLE STENGTH TESTER

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords