Fiberglass Yarn for Tissue Manufacturing - e-glass Fiberglass Yarn

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introductions

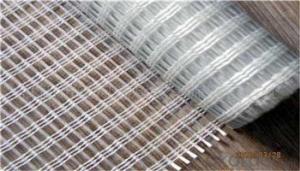

E-Glass Fiber Glass Yarn For Tissue Manufacturing is a kind of additional twisting and plying yam. With the characteristics of high strength, corrosion resistance, heat resistance and high moisture absorption, no-alkali yam has high electric insulation, so it used to produce weaved wires and cables’ wrap cladding, protection sleeve, train of mine, insulation materials of electric machinery, every yam of woven cloth and other industrial yam. It can also supply big and little paper cube and other cube yams with different shapes and different roll weight.

2.Product Features

Good Dispersibility.

Less fuzzy.

Density Even

3.Product Specifications

Product Code | Tex | diameter (um) | Sizing. | breaking strength | Twist |

CC7.5-22-1/2 110S | 44 | 7.5 | paraffin | ≥15.5 | 110±10 |

EC9-33-1/2 65S | 66 | 9 | ≥24.1 | 65±5 | |

EC8-25-1/2 65S | 50 | 8 | ≥19.2 | 65±5 | |

CC9-33-1/2 65S | 33 | 9 | ≥20.6 | 65±5 | |

CC11-44-6/0 | 264 | 11 | ≥81.6 | ||

CC11-44-1/3 110S | 132 | 11 | silane | ≥40.8 | 28±3 |

EC9-68-1/0 28Z | 68 | 9 | ≥18.0 | 28±3 |

4.FAQ

Storage:

Unless otherwise specified,It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

Empty Bobbins Returning:

The bobbins need to be returned and the buyer shall send bobbins to destination port and bear the related charge one they can filled in a full 40HQ.The seller shall handle the sea fright from destination port to China port.Customer should pay some deposite for the empty bobbins and the deposite can be treated as the payment for the future orders after the bobbins are sent back to the seller.

- Q: How does the resistance to aging of fiberglass yarn compare to other materials?

- Fiberglass yarn is widely acknowledged as having superior resistance to aging compared to numerous other materials. It is a synthetic substance made up of fine glass fibers, granting it exceptional durability and longevity. One of the primary benefits of fiberglass yarn is its ability to withstand degradation caused by various environmental elements. It exhibits high resistance to UV radiation, weathering, and corrosion, which are common factors contributing to the aging process in many materials. Consequently, fiberglass yarn can maintain its strength and integrity over long periods, establishing itself as a dependable option for diverse applications. Furthermore, fiberglass yarn possesses exceptional resistance to chemicals and moisture, further bolstering its ability to resist aging. This quality renders it suitable for use in harsh environments where exposure to corrosive agents or humid conditions is probable. In comparison to alternative materials like natural fibers (e.g., cotton or wool) or synthetic fibers (e.g., nylon or polyester), fiberglass yarn possesses a distinct advantage in terms of aging resistance. Natural fibers tend to deteriorate over time due to factors such as sunlight exposure, moisture, and insect damage, while synthetic fibers can be susceptible to UV degradation or chemical breakdown. Conversely, the distinctive composition of fiberglass yarn lends it a high level of resistance to these aging factors, enabling it to maintain its structural integrity over extended periods. In conclusion, the superiority of fiberglass yarn's resistance to aging is widely acknowledged when compared to numerous other materials. Its exceptional ability to withstand UV radiation, weathering, corrosion, chemicals, and moisture makes it a reliable choice for various applications where longevity and aging resistance are crucial.

- Q: Is fiberglass yarn suitable for use in heat insulation?

- Yes, fiberglass yarn is suitable for use in heat insulation. Its high temperature resistance and low thermal conductivity make it an effective material for insulating applications where heat needs to be contained or regulated.

- Q: How does the elasticity of fiberglass yarn affect its handling?

- The elasticity of fiberglass yarn can significantly affect its handling in various ways. Fiberglass yarn refers to yarn made of glass fibers, which are known for their strength and durability. The elasticity of this type of yarn refers to its ability to stretch and return to its original shape when force is applied. Firstly, the elasticity of fiberglass yarn can make it easier to handle during the weaving or knitting process. The yarn's stretchiness allows it to be pulled and manipulated without breaking, making it more forgiving for the user. This characteristic can be particularly beneficial when working with intricate or complex patterns that require frequent stretching and manipulation of the yarn. Secondly, the elasticity of fiberglass yarn can impact its behavior when it comes to tension and sagging. Fiberglass yarn with higher elasticity will have a greater ability to maintain tension, making it less likely to sag or lose shape over time. This can be advantageous in applications where the yarn needs to withstand continuous stress or weight without deforming. Furthermore, the elasticity of fiberglass yarn can affect its performance in applications such as fabrics or composites. In fabrics, the yarn's stretchiness can provide a degree of comfort and flexibility, allowing the material to conform to the body's movements. In composites, the yarn's elasticity can contribute to the material's ability to absorb and distribute stress, enhancing its overall strength and resilience. However, it is important to note that the elasticity of fiberglass yarn also has limitations. Excessive stretching or overloading can cause the yarn to lose its shape permanently or even break. Therefore, it is essential to consider the specific requirements and limitations of the project or application when selecting and handling fiberglass yarn.

- Q: How does fiberglass yarn affect the environment?

- Like any other production material, fiberglass yarn has both positive and negative environmental impacts. On the positive side, fiberglass is derived from abundant natural minerals like silica, limestone, and soda ash, making it a relatively sustainable resource compared to petroleum-based synthetic fibers. However, the manufacturing process of fiberglass yarn involves energy-intensive activities such as melting, extrusion, and weaving, which contribute to greenhouse gas emissions and climate change. Additionally, improper extraction of raw materials can lead to habitat destruction and soil erosion. Furthermore, fiberglass yarn is non-biodegradable and can persist in the environment, potentially contributing to microplastic pollution. Nevertheless, it is important to note that fiberglass is commonly used in durable applications like insulation, where the material is less likely to be released into the environment. To minimize the environmental impact of fiberglass yarn, manufacturers can adopt sustainable practices such as utilizing renewable energy sources, implementing efficient production methods, and actively recycling and reusing scrap materials. Additionally, consumers can make conscious choices by opting for products made from recycled fiberglass or exploring alternatives to fiberglass when possible. Overall, while fiberglass yarn has its environmental drawbacks, it also offers benefits in terms of resource availability and durability. By embracing responsible manufacturing practices and promoting sustainable consumption, the negative effects of fiberglass yarn on the environment can be reduced.

- Q: How does fiberglass yarn perform in corrosion resistance?

- Fiberglass yarn exhibits a high level of corrosion resistance. Its composition, comprising a substantial proportion of glass fibers, renders it naturally impervious to chemical degradation and rust. This attribute positions fiberglass yarn as an optimal selection for endeavors necessitating paramount corrosion resistance, like the fabrication of pipes, tanks, and assorted industrial machinery. Moreover, fiberglass yarn also showcases resistance against UV radiation, moisture, and extreme temperatures, thus reinforcing its capacity to counteract corrosion. Ultimately, fiberglass yarn emerges as a steadfast and long-lasting material, excelling in environments that pose corrosion-related apprehensions.

- Q: Can fiberglass yarn be used for making backpacks or bags?

- Backpacks or bags can indeed be made using fiberglass yarn. This type of yarn is renowned for its exceptional strength and durability, making it the perfect choice for producing robust items such as heavy-duty backpacks and bags. By weaving or knitting the yarn into fabrics, a solid and tear-resistant foundation is created for these products. Furthermore, fiberglass yarn provides outstanding resistance against chemicals, heat, and fire, thereby offering an additional layer of protection to the backpack or bag. However, it is important to consider that fiberglass yarn may not be suitable for applications that demand flexibility and softness, as it tends to be rigid and less comfortable compared to alternative materials.

- Q: Can fiberglass yarn be used for making moldings or trims?

- Certainly, moldings or trims can indeed be made using fiberglass yarn. Fiberglass possesses versatility as a material, being recognized for its strength, durability, and ability to withstand various environmental elements like moisture, chemicals, and UV radiation. These attributes make fiberglass yarn an ideal option for the manufacturing of moldings and trims, particularly in industries like automotive, construction, and marine. Fiberglass yarn can be woven or knitted into diverse shapes and sizes, enabling easy molding into the desired form for moldings or trims. Its flexibility and capacity to conform to intricate shapes make it a preferred choice for creating detailed designs and patterns. Moreover, fiberglass moldings and trims can be produced in different colors and finishes, offering a wide range of options to match specific aesthetic and design requirements. Furthermore, the inherent strength and durability of fiberglass yarn make it highly resistant to wear, tear, and impact, ensuring that moldings and trims crafted from it will endure daily use and retain their shape over an extended period of time. This makes fiberglass moldings and trims an excellent choice for applications necessitating longevity and resistance to damage, such as high-traffic areas or outdoor environments. Additionally, fiberglass yarn possesses excellent dimensional stability, meaning it undergoes minimal expansion or contraction with changes in temperature. This characteristic guarantees that moldings and trims made from fiberglass yarn will maintain their shape and size, even under extreme temperature conditions. In conclusion, fiberglass yarn is a suitable material for the production of moldings and trims due to its strength, durability, resistance to various environmental factors, flexibility, and ability to conform to complex shapes. With its array of available colors and finishes, as well as its longevity and dimensional stability, fiberglass yarn proves to be a practical and visually pleasing choice for diverse industries and applications.

- Q: Is fiberglass yarn resistant to moisture or humidity?

- Yes, fiberglass yarn is generally resistant to both moisture and humidity.

- Q: Can fiberglass yarn be used for making swimwear?

- Yes, fiberglass yarn can be used for making swimwear. It is often used in combination with other materials to create swimwear that is durable, lightweight, and has enhanced performance properties such as resistance to chlorine and UV rays.

- Q: Is fiberglass yarn resistant to electricity?

- Yes, fiberglass yarn is resistant to electricity. Fiberglass is an excellent insulator and does not conduct electricity. It is commonly used in electrical applications where insulation is required, such as in the manufacturing of electrical cables, wiring, and circuit boards. The non-conductive properties of fiberglass yarn help to prevent electrical current from flowing through the material, reducing the risk of electrical shock or short circuits. Additionally, fiberglass yarn is also resistant to heat and chemicals, making it a versatile and durable material for various electrical and industrial applications.

Send your message to us

Fiberglass Yarn for Tissue Manufacturing - e-glass Fiberglass Yarn

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords