Fiberglass Mat Tissue - Fiberglass Woven Roving Combo Mat 1250g 200~2600mm

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

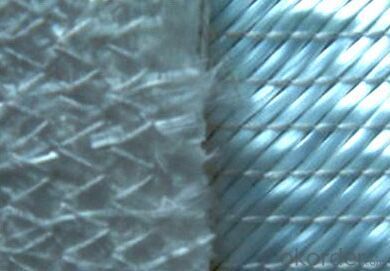

Structure of woven roving combo mat Description:

◎ This mat is a combination of woven roving and chopped glass fiber. The layer of chopped strand is stitched together with woven roving by polyester thread. It is mainly applied in the processes of molding compressing, pultrusion, RTM, filament winding etc..

◎ This fabric is compatible with UP Resin, Vinyl ester resin, epoxy resin system etc. It is widely used in vehicle bodies and panels, marine (boat hulls and decks), pipeline, lamination and structural profiles

Main Features of the woven roving combo mat

◎ Increase strength, reduce product weight and better surface finish.

◎ low resin-consumption and faster wet-out.

◎ Good manufacturability and mechanical properties

◎ Improved fatigue and impact resistance

Woven roving combo mat Images

Woven roving combo mat Specification:

| ||||||||||||||||||||||||||||||||||||||||

FAQ of Woven roving combo mat:

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: pultrusion, RTM, hand lay up, etc.

• Ultimate products: pultruded profiles, FRP body of boat, insulation board, automobile body.

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: How long does fiberglass mat tissue typically last?

- The duration of fiberglass mat tissue's lifespan is subject to fluctuation due to a variety of factors, including material quality, exposure to environmental conditions, and maintenance level. Typically, fiberglass mat tissue has a lifespan of 20 to 30 years. Nevertheless, by implementing appropriate installation techniques and consistent maintenance practices, it has the potential to endure beyond this time frame. It is crucial to emphasize that routine inspections and maintenance aid in the detection of any indications of deterioration or harm, permitting prompt repairs or replacements to guarantee its longevity.

- Q: How is fiberglass mat tissue made?

- The production of fiberglass mat tissue involves a wet-laid process, which encompasses several sequential steps. Initially, glass fibers are generated by melting and extruding glass through tiny apertures, resulting in continuous filaments. These filaments are subsequently coated with a sizing agent, enhancing their manipulability and fortifying the end product. Subsequently, the glass fibers are fragmented into shorter lengths to create a fiber mat. This operation is typically accomplished using either a knife or a rotary chopper. The fragmented fibers are then amassed and fashioned into a thin layer on a moving conveyor belt. Concurrently, a binder solution is formulated by blending a synthetic resin with water. This solution is then sprayed onto the fiber mat, ensuring the fibers become saturated and bonded together. The quantity of binder utilized determines the strength and flexibility of the final product. To guarantee the even distribution of the binder and the proper consolidation of the mat, it is passed through a sequence of rollers. These rollers exert pressure, eliminating excess water, compacting the fibers, and fostering adhesion among them. Once the mat is consolidated and attains the desired thickness, it undergoes a drying process, either in an oven or via hot air currents. This eliminates any remaining moisture and solidifies the binder, transforming it into a solid resin. Following the drying stage, the fiberglass mat tissue is wound onto rolls for storage or further processing. Due to its exceptional strength, resistance to corrosion, and thermal insulation properties, it serves as a reinforcement material in diverse industries such as construction, automotive, and aerospace.

- Q: Can fiberglass mat tissue be used for ceiling insulation?

- No, fiberglass mat tissue is not typically used for ceiling insulation. It is a material commonly used in the construction of composite materials, reinforcing plastic products, and for soundproofing purposes. Ceiling insulation is typically done using materials specifically designed for thermal and acoustic insulation, such as fiberglass batts, cellulose, or foam insulation boards.

- Q: Is fiberglass mat tissue suitable for railway infrastructure?

- Yes, fiberglass mat tissue is suitable for railway infrastructure. Fiberglass mat tissue is a strong and durable material that offers excellent resistance to corrosion, weathering, and chemical degradation. It is commonly used in the construction industry for reinforcing structures such as bridges, tunnels, and platforms. In the case of railway infrastructure, fiberglass mat tissue can provide several benefits. Firstly, it has high tensile strength, which means it can withstand the heavy loads and vibrations associated with train traffic. This helps to prevent cracking and structural damage, ensuring the longevity and safety of the railway system. Additionally, fiberglass mat tissue is non-conductive, which is a crucial characteristic for railway infrastructure. It helps to prevent the risk of electrical shocks and short circuits, which are common concerns in rail networks. This makes fiberglass mat tissue a reliable choice for railway infrastructure, especially in areas where electrical lines are present. Furthermore, fiberglass mat tissue is lightweight and easy to handle, making it convenient for installation in railway projects. It is also resistant to fire, making it a safe choice for railway infrastructure in terms of fire protection. Overall, fiberglass mat tissue is a suitable material for railway infrastructure due to its strength, durability, non-conductive nature, and fire resistance. Its use in railway construction can contribute to the reliability, longevity, and safety of the railway system.

- Q: Can fiberglass mat tissue be used for flooring applications?

- No, fiberglass mat tissue is not typically used for flooring applications. It is commonly used in industries such as automotive, construction, and marine for insulation, reinforcement, and insulation purposes. Flooring applications usually require different materials such as tiles, hardwood, laminate, or vinyl.

- Q: Can fiberglass mat tissue be used for insulating refrigeration units?

- Yes, fiberglass mat tissue can be used for insulating refrigeration units.

- Q: What is the flexural strength of fiberglass mat tissue?

- The flexural strength of fiberglass mat tissue refers to its ability to resist bending or flexing without breaking. It is typically high due to the reinforcing properties of the fiberglass material, making it suitable for applications requiring structural integrity and resistance to deformation.

- Q: Is fiberglass mat tissue resistant to acids?

- Fiberglass mat tissue is generally resistant to acids, thanks to its excellent corrosion resistance properties. This resistance extends to various acids. When combined with resin, fiberglass mat becomes a strong and durable material that can withstand exposure to a wide range of chemicals, including acids. However, it's important to note that the resistance of fiberglass mat tissue can still be affected by the specific type and concentration of acid. Highly concentrated or aggressive acids, in some cases, may cause damage or degradation to the material over time. Consequently, it is always advisable to consider the specific acid being used and consult the manufacturer's recommendations for compatibility before exposing fiberglass mat tissue to an acidic environment.

- Q: Is fiberglass mat tissue resistant to chemicals?

- Yes, fiberglass mat tissue is generally resistant to chemicals. The composition of fiberglass mat tissue, which consists of fine glass fibers bonded together with a resin, provides it with excellent chemical resistance properties. This resistance allows the fiberglass mat tissue to withstand exposure to a wide range of chemicals without deteriorating or losing its structural integrity. However, it is important to note that the specific chemical resistance of fiberglass mat tissue may vary depending on the type and concentration of the chemical it comes into contact with. Therefore, it is always advisable to consult the manufacturer's guidelines or conduct appropriate testing to ensure compatibility with specific chemicals.

- Q: What is the maximum temperature that fiberglass mat tissue can withstand?

- The specific type of fiberglass material being utilized determines the maximum temperature that fiberglass mat tissue can endure. Typically, fiberglass mat tissues are engineered to withstand temperatures of up to 600 degrees Fahrenheit (315 degrees Celsius). Nevertheless, it should be emphasized that the temperature resistance may fluctuate due to various factors, including material thickness, manufacturing techniques, and the intended usage. For precise information regarding the maximum temperature tolerance of a specific fiberglass mat tissue, it is advised to refer to the manufacturer's specifications or technical data sheets.

Send your message to us

Fiberglass Mat Tissue - Fiberglass Woven Roving Combo Mat 1250g 200~2600mm

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords