FRP Pultrusion Profiles Fiberglass Reinforced Plastic Mop Handle Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

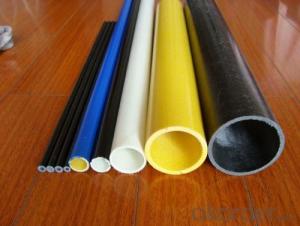

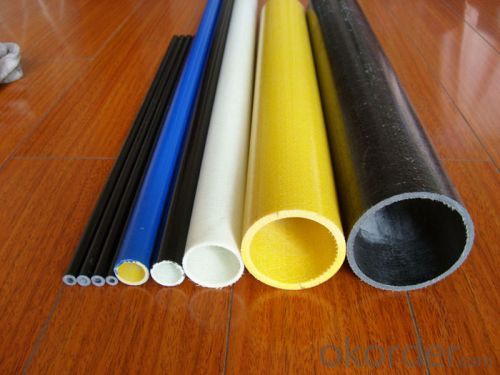

Specifications of Fiberglass Reinforced Plastic Tube for Mop Handle:

1. corrosion resistant, high strength but lightweight

2. colorful, much more long-lasting than normal plastic

Introduction of Fiberglass Reinforced Plastic Tube for Mop Handle:

FRP Tool handles is made of high-strength fiberglass as reinforcing material, thermosetting resin as the base, heated in précised die to cure into tubes or rods. Those FRP tool handles have excellent properties such as: light in weight, high strength, anti-aging & beautiful appearance, and is widely used in the gardening tool industry as a fiberglass handle, it is an ideal substitute for wooden handle, iron handle and aluminum handle.

List of Fiberglass Reinforced Plastic Tube for Mop Handle:

item | Size(mm) | Weight(kg/m) |

FRP round tube | 18*11 | 0.308 |

25*21 | 0.28 | |

30*24 | 0.43 | |

30*25.2 | 0.38 | |

30*22 | 0.59 | |

40*34 | 0.615 | |

40*30 | 0.97 | |

45*39 | 0.77 | |

50*42 | 1.02 | |

50*45 | 0.6 | |

51*45 | 0.75 |

- Q: Are FRP pultrusion profiles resistant to moisture or humidity?

- Yes, FRP pultrusion profiles are highly resistant to moisture and humidity. The combination of fiberglass reinforcement and resin matrix used in their construction makes them non-corrosive and impervious to water absorption. This inherent resistance ensures their durability and performance in humid or moist environments without compromising their structural integrity.

- Q: Are FRP pultrusion profiles resistant to chemical spills or leaks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to chemical spills or leaks. One of the key advantages of using FRP as a construction material is its exceptional chemical resistance. FRP profiles are made by impregnating continuous fibers with a thermosetting resin, resulting in a strong and durable composite material. The resin used in FRP pultrusion profiles is typically selected based on the specific chemical environment in which the profiles will be exposed. This allows for customization and optimization of the composite's resistance to various chemicals. Additionally, the fibers used in FRP are generally chemically inert, further enhancing the resistance of the profiles to chemical spills or leaks. FRP pultrusion profiles have demonstrated excellent resistance to a wide range of chemicals, including acids, alkalis, solvents, and corrosive substances. They are commonly used in industries such as chemical processing, water and wastewater treatment, oil and gas, and marine applications, where exposure to aggressive chemicals is prevalent. In addition to their chemical resistance, FRP pultrusion profiles offer several other advantages. They are lightweight, yet possess high strength and stiffness, making them ideal for applications that require structural integrity. They are also non-conductive, non-magnetic, and have excellent electrical insulation properties. Overall, FRP pultrusion profiles are a reliable choice for environments where chemical spills or leaks are a concern, as they provide robust resistance to a wide range of chemicals, ensuring long-lasting performance and minimal maintenance requirements.

- Q: Are FRP pultrusion profiles resistant to alkalis?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to alkalis. This is due to the fact that FRP composites are non-metallic materials that are composed of a polymer matrix reinforced with fibers, such as glass or carbon. The polymer matrix in FRP pultrusion profiles provides excellent resistance to alkalis, making them suitable for applications in environments where alkalis are present, such as chemical processing plants, wastewater treatment facilities, or marine structures. However, the specific resistance of FRP pultrusion profiles to alkalis may vary depending on the type of polymer resin used and the concentration and temperature of the alkali solution. Therefore, it is important to consult the manufacturer's specifications or conduct specific tests to ensure the compatibility of FRP pultrusion profiles with the intended alkali environment.

- Q: What are the insulation properties of FRP pultrusion profiles?

- FRP pultrusion profiles have excellent insulation properties due to the nature of the materials used in their composition. FRP, which stands for Fiber Reinforced Polymer, combines the strength of the fiber reinforcement with the insulating properties of the polymer matrix. The insulation properties of FRP pultrusion profiles are primarily determined by the polymer matrix, which is typically made of thermosetting resins such as polyester, vinyl ester, or epoxy. These resins have low thermal conductivity, meaning they are poor conductors of heat. This property allows FRP pultrusion profiles to effectively reduce heat transfer through conduction. In addition to low thermal conductivity, FRP pultrusion profiles also exhibit excellent electrical insulation properties. The polymer matrix acts as an insulator, preventing the flow of electric current and reducing the risk of electrical accidents or damage to equipment. Furthermore, FRP pultrusion profiles are also resistant to moisture, chemicals, and UV radiation, which further enhances their insulation properties. Moisture and chemicals can degrade the insulation properties of materials, but FRP is highly resistant to these factors, ensuring long-term insulation performance. Overall, FRP pultrusion profiles offer superior insulation properties, making them an ideal choice for applications where thermal or electrical insulation is required. They provide a reliable and durable solution for various industries, including construction, electrical, and transportation.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food packaging?

- Yes, FRP pultrusion profiles are generally resistant to the chemicals commonly used in food packaging. The combination of fiberglass reinforcement and resin matrix used in FRP profiles provides excellent chemical resistance, making them a suitable choice for applications involving contact with food packaging chemicals. However, it is always recommended to consult with the manufacturer or supplier to ensure specific compatibility with the chemicals involved.

- Q: Can FRP pultrusion profiles be used in the construction of railway platforms?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of railway platforms. FRP profiles are lightweight, durable, and corrosion-resistant, making them suitable for various structural applications. They offer high strength-to-weight ratio, reducing the load on the platform structure while maintaining structural integrity. Additionally, FRP profiles can be customized to meet specific design requirements, providing flexibility in creating efficient and long-lasting railway platforms.

- Q: Are FRP pultrusion profiles resistant to rotting or decaying?

- Yes, FRP pultrusion profiles are highly resistant to rotting or decaying. FRP, or fiber-reinforced polymer, is a composite material that consists of a polymer matrix reinforced with fibers. This combination makes FRP pultrusion profiles highly durable and resistant to environmental factors such as moisture, chemicals, and UV radiation, which can lead to rotting or decaying in other materials. Therefore, FRP pultrusion profiles are an excellent choice for applications where long-term resistance to rotting or decaying is required.

- Q: What are the typical load-bearing capacities of FRP pultrusion profiles?

- The typical load-bearing capacities of FRP pultrusion profiles can vary depending on factors such as the specific design and dimensions of the profile, as well as the type and quality of the material used. However, FRP pultrusion profiles are known for their high strength-to-weight ratio and can typically handle significant loads, often exceeding those of traditional materials like steel or aluminum. It is best to consult with manufacturers or engineering experts to determine the exact load-bearing capacities of specific FRP pultrusion profiles.

- Q: What are the limitations of FRP pultrusion profiles?

- There are several limitations associated with FRP (Fiber Reinforced Polymer) pultrusion profiles. 1. Limited Shapes and Sizes: Pultrusion technology is primarily suitable for producing linear profiles with constant cross-sections. It is challenging to create complex shapes or profiles with varying cross-sections using this manufacturing process. 2. High Initial Costs: The initial setup costs for pultrusion equipment can be quite high, making it less economically viable for smaller production runs. The machinery and molds required for pultrusion can be expensive and may require significant investment. 3. Limited Material Choices: While FRP pultrusion profiles offer excellent strength and corrosion resistance, the range of materials available for pultrusion is relatively limited. Typically, only a few types of reinforcing fibers, such as glass or carbon, are used. This limitation restricts the range of properties and applications of pultruded profiles. 4. Surface Finish: Pultruded profiles often have a rough surface finish, which may not be suitable for certain applications where a smooth or aesthetically pleasing appearance is desired. Additional steps, such as post-processing or coating, may be required to achieve the desired surface finish. 5. Tolerance Control: Maintaining tight dimensional tolerances can be challenging in pultrusion due to the inherent nature of the process. Variations in resin flow, fiber distribution, and curing can affect the final dimensions of the profile, which may require additional quality control measures. 6. Limited Design Flexibility: Unlike traditional manufacturing methods like extrusion or injection molding, pultrusion offers limited design flexibility. The constant cross-section of pultruded profiles restricts the ability to incorporate intricate features or varying thicknesses in the design. 7. Brittle Behavior: FRP pultrusion profiles tend to exhibit brittle behavior when subjected to high impact or sudden loads. While they possess high strength and stiffness, they may not have the same toughness as other materials like metals, making them prone to fracture under certain conditions. Despite these limitations, FRP pultrusion profiles offer numerous advantages such as high strength-to-weight ratio, corrosion resistance, and design versatility within their limitations. These profiles find applications in industries such as construction, aerospace, automotive, and marine, where their unique properties outweigh the drawbacks.

- Q: Can FRP pultrusion profiles be used in the construction and building materials industry?

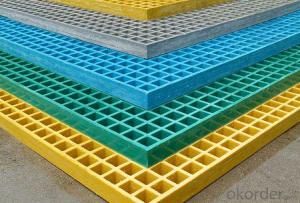

- Yes, FRP pultrusion profiles can be effectively used in the construction and building materials industry. These profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and dimensional stability, making them suitable for a wide range of applications including structural elements, handrails, gratings, and reinforcements. Additionally, FRP pultrusion profiles can be easily customized to meet specific project requirements, making them a popular choice in the industry.

Send your message to us

FRP Pultrusion Profiles Fiberglass Reinforced Plastic Mop Handle Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords