Fiberglass Mat Tissue - Multiaxial Fabric-UD Series 400/50g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

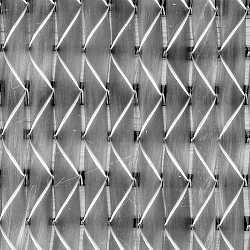

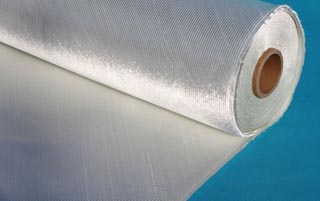

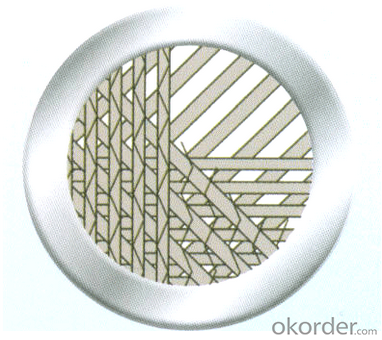

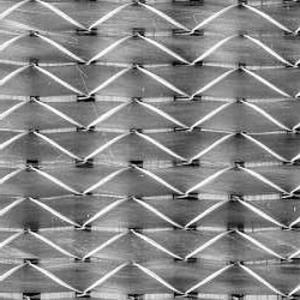

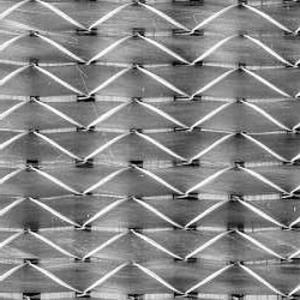

Description Multiaxial fabrics is non-crimp, multi-axis and multi-layered reinforcements. Layer count, orientation, weight and fiber content of the layers vary based on product line and application. The layers are stitched via polyester yarn. Fabrics can be produced using multiple axis(0°,90°,+45°,-45°), or combined with chopped mat and multiple layers of veil and /or non-woven materials. The typical application of this kind of products are wind energy, marine/ship building, recreation /leisure products, automotive, aerospace & defense etc.

Images

Specifications

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

7. What is the Production Lead Time?

1 *40HQ each day.

- Q: Can fiberglass mat tissue be used for insulation in refrigeration systems?

- Indeed, insulation in refrigeration systems can be accomplished by employing fiberglass mat tissue. Fiberglass, renowned for its remarkable thermal characteristics and moisture resistance, is a prevalent choice for insulation purposes. Specifically engineered to provide insulation, fiberglass mat tissue finds frequent application in the construction of refrigeration systems. Its purpose is to reduce heat transfer and uphold the desired temperature within the system. Moreover, fiberglass possesses the advantages of being lightweight, long-lasting, and easily installable, rendering it a favored option for refrigeration system insulation.

- Q: What are the different reinforcement orientations available for fiberglass mat tissue?

- The different reinforcement orientations available for fiberglass mat tissue include random chopped strand mat (CSM), continuous strand mat (CSM), woven roving, and unidirectional fiberglass.

- Q: How is fiberglass mat tissue used in the production of sports equipment?

- The unique properties and advantages of fiberglass mat tissue make it widely used in the production of sports equipment. This material, made from fine glass fibers bonded together with a binder, is a non-woven fabric with a smooth texture. Despite being lightweight, it is strong and durable. In the manufacturing of sports equipment, fiberglass mat tissue is commonly used as a reinforcing layer. Its purpose is to enhance the strength and rigidity of the final product, making it more resistant to impact and stress. This is particularly important in sports equipment where durability and performance are crucial, such as surfboards, skateboards, snowboards, and tennis rackets. For instance, in the construction of a surfboard, fiberglass mat tissue is typically layered over a foam core and then impregnated with epoxy resin. This combination creates a structure that can withstand the forces exerted by the waves while remaining lightweight. Similarly, in snowboards and skateboards, fiberglass mat tissue is applied to the wooden core to provide additional strength and stiffness, which improves control and responsiveness. Furthermore, fiberglass mat tissue is also utilized in the production of protective gear like helmets and shin guards. By incorporating this material into the manufacturing process, these items can become more impact resistant and capable of absorbing shocks. This is particularly important in high-risk sports, as the fiberglass mat tissue acts as a protective layer, dispersing and diminishing the force of impacts. To summarize, fiberglass mat tissue is vital in the production of sports equipment as it reinforces structures, enhances strength and durability, and improves performance. Its lightweight nature and superior mechanical properties make it an ideal choice for various sporting applications, ensuring athletes can rely on their equipment to perform well while minimizing the risk of injury.

- Q: Does anyone know the hardness value of the heat conductive gasket? Does it contain the hardness of the carrier (glass fiber)?

- I know that GLPOLY has a heat conductive gel gasket that looks like an PCB circuit board for an uneven interface

- Q: Is fiberglass mat tissue resistant to mold and mildew?

- Yes, fiberglass mat tissue is resistant to mold and mildew due to its non-porous and moisture-resistant properties.

- Q: Can fiberglass mat tissue be used for making electrical enclosures?

- No, fiberglass mat tissue is not suitable for making electrical enclosures. Electrical enclosures require materials that have good electrical insulation properties to prevent electrical shocks and short circuits. Fiberglass mat tissue is primarily used for reinforcement in composites and does not possess the necessary electrical insulation properties. Materials such as plastics, polymers, or metals with appropriate electrical insulation characteristics should be used for making electrical enclosures.

- Q: Can fiberglass mat tissue be used in structural applications?

- Indeed, structural applications can make use of fiberglass mat tissue. This lightweight and flexible material is frequently employed as reinforcement in construction and engineering endeavors. It is often combined with resin or concrete to enhance the structural integrity of diverse components. The remarkable strength-to-weight ratio of fiberglass mat tissue renders it exceptionally fitting for reinforcing walls, roofs, and floors. Furthermore, its resistance to corrosion, moisture, and chemicals allows for its utilization in diverse environments. The wide-ranging applicability and enduring nature of fiberglass mat tissue contribute to its widespread preference in structural applications.

- Q: Can fiberglass mat tissue be used for insulation in research laboratories?

- Yes, fiberglass mat tissue can be used for insulation in research laboratories. Fiberglass mat tissue is a common material used for thermal and acoustic insulation due to its excellent insulation properties. It is highly resistant to heat, moisture, and chemicals, making it suitable for laboratory settings. Additionally, fiberglass mat tissue is lightweight and easy to install, allowing for quick and efficient insulation in research laboratories. Its low thermal conductivity helps to maintain stable temperature conditions, ensuring optimal conditions for experiments and reducing energy consumption. Therefore, fiberglass mat tissue is a viable choice for insulation in research laboratories.

- Q: How does the width of fiberglass mat tissue affect its installation?

- The width of fiberglass mat tissue affects its installation by determining the amount of coverage it provides per roll. A wider mat tissue will cover a larger area with each roll, reducing the number of rolls needed for installation. This can save time and effort during the installation process. Additionally, a wider width may also provide better overall strength and stability to the installed fiberglass mat tissue.

- Q: What is the shear strength of fiberglass mat tissue?

- The shear strength of fiberglass mat tissue depends on various factors such as the thickness of the mat, the type and quality of the fiberglass material used, and the manufacturing process. However, in general, fiberglass mat tissue has a relatively high shear strength compared to other materials. Fiberglass mat tissue is typically composed of multiple layers of glass fibers bonded together with a resin matrix. The combination of these materials results in a strong and durable product. The shear strength of fiberglass mat tissue allows it to withstand significant forces and resist deformation or failure when subjected to shear stress. To determine the specific shear strength of a particular fiberglass mat tissue, it is necessary to refer to the product specifications provided by the manufacturer. These specifications typically include information about the material's shear strength, as well as other mechanical properties. It is important to note that the shear strength of fiberglass mat tissue can vary depending on the specific application and conditions in which it is used. Factors such as temperature, moisture, and exposure to chemicals can influence the material's performance. Therefore, it is always recommended to consult the manufacturer's guidelines and engineering experts to ensure the proper selection and application of fiberglass mat tissue for a particular project.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD Series 400/50g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords