Fiberglass Mat Tissue - E-Glass Fiberglass Type Jushi Fiberglass Chopped Strand Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

E-Glass Fiberglass Type Jushi Fiberglass Chopped Strand Mat

Introduction:

Chopped Strand Mat is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the application by hand lay-up FRP moldings, such as, various sheets and panels, boat hulls, boat tubs, cooling towers, corrosion resistant, vehicles, etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

Consistent thickness and stiffness;

Rapid impregnating and good compatibility with resin;

Superior wet through with less air trap;

Good mechanical properties and high strength of parts.

Superior acid corrosion resistance

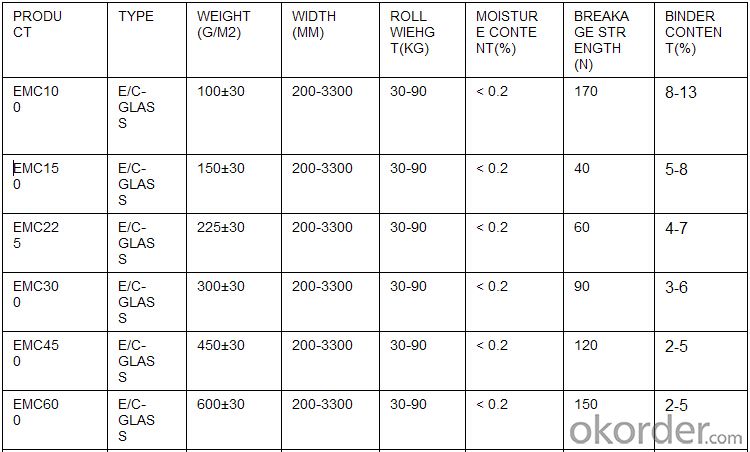

Technical Data:

Packaging:

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Can fiberglass mat tissue be used for soundproofing?

- Indeed, soundproofing can be achieved with the utilization of fiberglass mat tissue. Renowned for its remarkable sound absorption capabilities, fiberglass proves to be an exceptional choice. Whether employed as a mat or tissue, it effectively diminishes noise transmission by absorbing and attenuating sound waves. The porous composition of fiberglass enables it to capture and disperse sound energy, rendering it a perfect material for soundproofing purposes. Furthermore, fiberglass possesses the advantages of being lightweight, flexible, and straightforward to install, thus making it an exceedingly convenient option for soundproofing endeavors.

- Q: Is fiberglass mat tissue suitable for insulation in cold storage facilities?

- Cold storage facilities can benefit from the use of fiberglass mat tissue as an insulation material. Fiberglass possesses remarkable thermal insulation properties, effectively blocking heat transfer and maintaining low temperatures in the storage area. Moreover, fiberglass is moisture-resistant and does not absorb water, making it ideal for environments prone to condensation and moisture. The installation of fiberglass mat tissue is simple and offers a cost-effective solution for insulating the walls, ceilings, and floors of cold storage facilities. Ultimately, the use of fiberglass mat tissue plays a vital role in preserving the desired cold temperatures and preventing any thermal leaks in these facilities.

- Q: Can fiberglass mat tissue be used for making lightweight countertops?

- Yes, fiberglass mat tissue can be used for making lightweight countertops. Fiberglass mat tissue is a thin, lightweight material made from fine glass fibers, which makes it an ideal choice for creating lightweight countertops. It provides strength and durability while also being easy to work with and mold into various shapes and sizes. Additionally, fiberglass mat tissue is resistant to moisture, chemicals, and heat, making it a suitable material for countertops that may be exposed to these elements. Overall, using fiberglass mat tissue for making lightweight countertops is a practical and efficient solution.

- Q: How is fiberglass mat tissue made?

- Fiberglass mat tissue is made through a process called wet-laid process, which involves several steps. First, glass fibers are created by melting and extruding glass through small holes to form continuous filaments. These filaments are then coated with a sizing agent to improve their handling properties and strengthen the final product. Next, the glass fibers are chopped into short lengths to create a fiber mat. This is usually done using a knife or a rotary chopper. The chopped fibers are then collected and formed into a thin layer on a moving conveyor belt. In parallel to this, a binder solution is prepared by mixing a synthetic resin with water. This solution is then sprayed onto the fiber mat to wet and bind the fibers together. The amount of binder used determines the strength and flexibility of the final product. To ensure uniform distribution of the binder and proper consolidation of the mat, it passes through a series of rollers. These rollers apply pressure to remove excess water, squeeze the fibers together, and promote bonding between the fibers. Once the mat is consolidated and the desired thickness is achieved, it is dried in an oven or through hot air currents. This removes any remaining moisture and cures the binder, transforming it into a solid resin. After drying, the fiberglass mat tissue is wound into rolls for storage or further processing. It can be used as a reinforcing material in various industries, such as construction, automotive, and aerospace, due to its excellent strength, corrosion resistance, and thermal insulation properties.

- Q: Is fiberglass mat tissue resistant to vibrations?

- Yes, fiberglass mat tissue is resistant to vibrations. The strong and flexible nature of fiberglass makes it suitable for absorbing and dampening vibrations, making it an ideal material for applications where vibration resistance is required.

- Q: Does fiberglass mat tissue provide any moisture insulation?

- Yes, fiberglass mat tissue provides some level of moisture insulation. Fiberglass is known for its water-resistant properties, and the mat tissue made from fiberglass helps to further enhance this characteristic. It acts as a barrier against moisture, preventing it from seeping through and causing damage to underlying materials. However, it is important to note that fiberglass mat tissue is not completely waterproof and may allow some moisture to penetrate over time. Therefore, it is recommended to use additional moisture insulation materials in situations where complete waterproofing is required.

- Q: Can fiberglass mat tissue be used for insulation boards?

- Yes, fiberglass mat tissue can be used for insulation boards. Fiberglass mat tissue is a lightweight, flexible material made from fine glass fibers bonded together with a resin. It has excellent thermal insulation properties, making it an ideal choice for insulation boards. The mat tissue can be easily cut to fit various shapes and sizes, and it can be used to insulate walls, roofs, floors, and other areas of a building. It is also resistant to moisture, mold, and mildew, ensuring long-lasting insulation performance. Additionally, fiberglass mat tissue is fire-resistant, further enhancing its suitability for insulation applications. Overall, fiberglass mat tissue is a versatile and effective material for insulation boards.

- Q: Can fiberglass mat tissue be used for making swimming pool shells?

- Yes, fiberglass mat tissue can be used for making swimming pool shells.

- Q: How does the width of fiberglass mat tissue affect its installation?

- The width of fiberglass mat tissue can have an impact on its installation process. When considering the width of fiberglass mat tissue, it is important to take into account the specific application or project requirements. A wider fiberglass mat tissue can offer several advantages during installation. Firstly, it allows for greater coverage area, reducing the number of overlaps needed and potentially saving installation time. This can be particularly beneficial in large-scale projects where efficiency is crucial. Additionally, a wider width can provide better overall coverage and reduce the risk of potential gaps or weak spots in the installation. This can result in a more consistent and reliable finished product, ensuring enhanced performance and durability. However, it is worth noting that a wider fiberglass mat tissue may also present certain challenges during installation. It can be more difficult to handle and maneuver, especially when working in tight or confined spaces. This can require additional care and attention to ensure proper alignment and smooth application. Furthermore, the width of fiberglass mat tissue can impact the amount of resin or adhesive required for installation. A wider width may necessitate a larger quantity of resin or adhesive, potentially increasing the overall project cost. Ultimately, the choice of fiberglass mat tissue width should be based on the specific needs and constraints of the project. Factors such as the size of the installation area, the level of coverage required, and the available resources should all be taken into consideration to determine the most suitable width for the application.

- Q: How does fiberglass mat tissue compare to spray foam insulation?

- Fiberglass mat tissue and spray foam insulation differ in terms of their insulation materials, characteristics, and benefits. Fiberglass mat tissue, a woven fiberglass insulation, is commonly used for thermal insulation in walls, roofs, and attics. It effectively resists heat transfer and provides an additional safety benefit with its fire-resistant properties. In contrast, spray foam insulation is a liquid that expands into a solid foam upon application. It fills in cracks and gaps, creating an airtight seal that prevents air leakage and reduces energy loss. It is also known for its soundproofing capabilities. Regarding installation, fiberglass mat tissue comes in large rolls or batts that require cutting and fitting. It must be carefully handled and may necessitate the use of protective equipment due to potential skin and respiratory irritation. On the other hand, spray foam insulation is applied using specialized equipment that sprays the liquid foam onto surfaces. It quickly expands, filling gaps and hardening within a short time. This makes it a convenient choice for insulating hard-to-reach areas or irregularly shaped spaces. In terms of cost, fiberglass mat tissue is generally more economical for purchase and installation compared to spray foam insulation. However, spray foam insulation provides superior air sealing and can result in higher long-term energy savings. In summary, each insulation type has its own advantages. Fiberglass mat tissue excels in thermal insulation, while spray foam insulation is ideal for air sealing and soundproofing. The choice between the two depends on factors such as budget, desired insulation performance, and project requirements.

Send your message to us

Fiberglass Mat Tissue - E-Glass Fiberglass Type Jushi Fiberglass Chopped Strand Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords