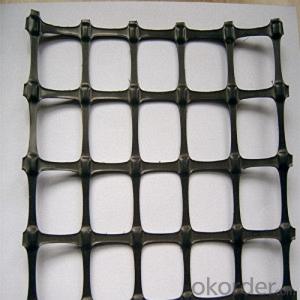

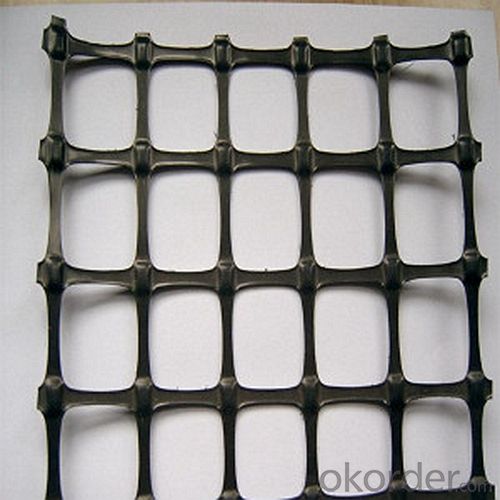

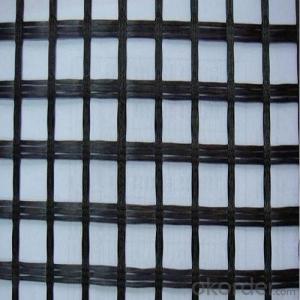

Landscaping Geotextile - Fiberglass Geogrid with Low Elongation and Good Toughness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Fiberglass geogrid is a kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt. It is warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant. Moreover, the composite property of coating with asphalt makes full protection of the fiberglass matrix and greatly improves its wear and shear resistance. All the advantageous functions make the product have a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Fiberglass Geogrid features

1. Light weight, high tensile strength, high modulus, low elongation and good

toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Packaging & Shipping

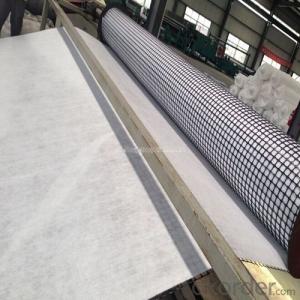

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

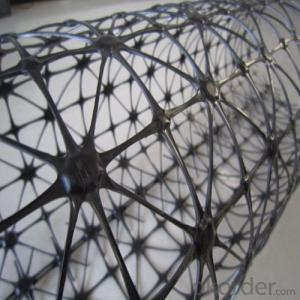

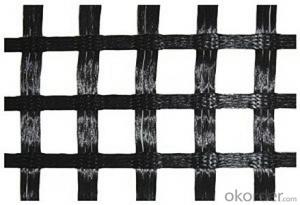

A: Yes, please check the pictures:

- Q: How do geotextiles help in groundwater protection?

- Geotextiles help in groundwater protection by acting as a barrier that prevents the infiltration of pollutants into the groundwater system. They are used in various applications such as drainage systems, landfills, and erosion control, where they provide filtration and separation of soil particles, ensuring that only clean water enters the groundwater.

- Q: Characteristics of nonwoven geotextiles

- Non-woven geotextile has many advantages: 1) air permeability 2) filterability 3) insulation 4) water absorption 5) waterproof 6) stretch 7) not disheveled 8) feel good, soft 9) light 10) Can be restored 11) without the direction of the fabric 12) compared with the textile production of high productivity, production speed 13) low prices, can be mass production and so on. Disadvantages are: 1) Compared with the textile fabric strength and durability is poor; 2) can not be washed as other fabrics; 3) fiber arranged in a certain direction, so easy to split from the right angle and so on. Therefore, the improvement of the production method has been mainly focused on preventing the improvement of the division.

- Q: How are geotextiles incorporated into engineering designs?

- Geotextiles are commonly incorporated into engineering designs as they provide a range of benefits such as soil stabilization, erosion control, drainage improvement, and reinforcement. They can be used in various applications such as road construction, retaining walls, embankments, landfills, and coastal protection. Geotextiles are often placed between soil layers to separate and reinforce them, enhancing the overall stability and durability of the project.

- Q: What is the difference between a hard pipe and a mesh plastic blind ditch?

- Different products, all play the role of drainage ditch need to wrap geotextered soft water pipe does not require geotextile package. Huazhi geotextile material answer

- Q: Geotextile types and role of geotextiles which types, respectively, what role, filament geotextile, short geotextile, composite geotextile, respectively, what role? More

- 1, acupuncture non-woven geotextile, specifications 100g / m2-1000g / m2 between any choice, the main raw material is the use of polyester staple fiber or polypropylene staple fiber, made by acupuncture, the main purposes are: river, sea, lake Embankment slope protection, reclamation, wharf, ship lock flood control and other projects, is through the filter to play a soil and water conservation and effective way to prevent piping. Second, acupuncture non-woven fabrics and PE film composite geotextile, specifications have a cloth a film, two cloth a film, the largest width of 4.2 meters The main raw material is to use polyester staple fiber acupuncture non-woven, PE film through the composite , The main purpose is anti-seepage, apply to railways, highways, tunnels, subways, airports and other projects. Third, non-woven and woven composite geotextile, a variety of non-woven and polypropylene filament woven composite, non-woven and plastic woven composite, for the basis of reinforcement, adjust the permeability coefficient of the basic engineering facilities. Features: light weight, low cost, corrosion resistance, with a filter, drainage, isolation, enhance the excellent performance. Use: widely used in water conservancy, electricity, mines, roads and railways and other geotechnical projects: l, soil separation of the filter material; 2, reservoirs, mine mineral processing of drainage materials, high-rise building drainage materials; Of the anti-erosion material; geotextile features 1, high strength, due to the use of plastic fibers, in dry and wet state can maintain sufficient strength and elongation. 2, corrosion-resistant, in different pH of the soil and water can be long-term corrosion resistance. 3, good water permeability between the fiber gap, it has a good water permeability. 4, good microbial resistance to micro-organisms, insects are not damaged. 5, construction convenience

- Q: What are the specifications for geotextiles in drainage projects?

- The specifications for geotextiles in drainage projects typically include factors such as the material type, weight, permeability, tensile strength, and filtration properties. The geotextile material should be appropriate for the specific drainage application and capable of withstanding the anticipated loads and environmental conditions. It should also have a specific weight or thickness to ensure proper performance. The permeability of the geotextile is important to allow water to flow through while preventing soil particles from clogging the drainage system. Tensile strength is a crucial factor as it determines the geotextile's ability to withstand installation stresses and potential loads. Lastly, filtration properties are essential to retain soil particles while allowing water to pass through.

- Q: Can geotextiles be used in coastal erosion control structures?

- Yes, geotextiles can be used in coastal erosion control structures. Geotextiles are commonly used to stabilize slopes, reinforce soil, and control erosion in various construction projects. In coastal areas, they can be employed to prevent erosion of beaches, dunes, or shorelines by acting as a barrier against the movement of sediment and soil. Geotextiles provide an effective solution for coastal erosion control structures due to their permeability, strength, and ability to withstand harsh environmental conditions.

- Q: What are the different geotextile weight classes and their applications?

- Geotextile weight classes range from lightweight to heavyweight, typically categorized as classes 1 through 5. Class 1 geotextiles are lightweight and used for erosion control, filtration, and separation in landscaping and gardening projects. Class 2 and 3 geotextiles are medium-weight and commonly used for road construction, pavement reinforcement, and drainage applications. Class 4 geotextiles are heavy-duty and suitable for shoreline protection, slope stabilization, and landfill lining. Lastly, Class 5 geotextiles are the heaviest and used in geotechnical engineering for applications such as soil stabilization, embankment reinforcement, and railway construction.

- Q: How do geotextiles help with load transfer in foundation systems?

- Geotextiles help with load transfer in foundation systems by providing a stable and strong layer of reinforcement. They distribute the load from the structure evenly to the underlying soil, preventing differential settlement and improving overall stability. Additionally, geotextiles can enhance the bearing capacity of weak soils and minimize the potential for erosion, thus increasing the longevity and performance of the foundation system.

Send your message to us

Landscaping Geotextile - Fiberglass Geogrid with Low Elongation and Good Toughness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords