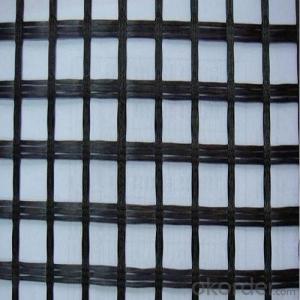

Fiberglass Geogrid Roadbed Reinforcement with Low Elongation and Good Toughness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description

Geogrids with gravel chippings for fill material provides horizontal stability of the road surface bed (fixation of gravel chippings under surface to prevent horizontal rupture).

Geogrid application allows using gravel chippings of different kinds.

Geogrid application filled with ground material is one of the easy of soil reinforcement.

The thickness of such construction may be 50% less than the thickness of standard replacement which allows avoiding costly soil replacement.

Tensile Strength: 25-25KN; 30-30KN; 50-50KN; 80-80KN; 100-100KN; 120-120KN;

Road Size: 3.95x100m; as customer required;

Application

1. Roadbed reinforcement in highway, railway and municipal road, prevent road surface crack

2. Reinforcement and separation in dam and river, improve soft soil bearing capacity and stability.

Application

1. Roadbed reinforcement in highway, railway and municipal road, prevent road surface crack

2. Reinforcement and separation in dam and river, improve soft soil bearing capacity and stability.

fiberglass geogrid/glass fiber geogrid with CE certificate Introduction: Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is composed of fiberglass filaments that are coated with an inorganic sizing agent

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Geotextile and geogrid the same do

- Not the same, this is two kinds of products, my user name professional manufacturer phone! The The

- Q:How do geotextiles contribute to soil moisture retention?

- Geotextiles contribute to soil moisture retention by acting as a barrier that prevents water evaporation from the soil surface. They also help in distributing water evenly throughout the soil profile by reducing the rate of infiltration and promoting slow water percolation. Additionally, geotextiles can prevent soil erosion, which can lead to the loss of moisture from the soil. Overall, geotextiles play a crucial role in retaining soil moisture and promoting healthy plant growth.

- Q:What are the key factors to consider when selecting a geotextile?

- When selecting a geotextile, some key factors to consider are the specific application requirements, the type and strength of the geotextile, its permeability, durability, and compatibility with the surrounding soil or materials. Additionally, factors such as the installation method, environmental conditions, and budget should also be taken into account.

- Q:What are the main functions of geotextiles?

- The main functions of geotextiles are to provide separation, filtration, reinforcement, and drainage in various civil engineering applications. They help prevent the mixing of different soil layers, enhance soil stability, control erosion, and allow for the efficient flow of water.

- Q:How do geotextiles improve the performance of geosynthetic tubes?

- Geotextiles improve the performance of geosynthetic tubes by providing reinforcement and filtration capabilities. They act as a barrier, preventing soil particles from entering and clogging the tubes while allowing water to pass through. This helps maintain the structural integrity and efficiency of the tubes, enhancing their overall performance.

- Q:What types of geotextiles are suitable for reinforcement purposes?

- There are several types of geotextiles that are suitable for reinforcement purposes, including woven geotextiles, non-woven geotextiles, and knitted geotextiles. These geotextiles are designed to provide strength, stability, and durability when used in soil stabilization, erosion control, and retaining wall applications.

- Q:How are geotextiles used in drainage systems?

- Geotextiles are used in drainage systems as a filtration and separation layer. They prevent the migration of fine particles into the drainage system, while allowing water to pass through freely. This helps in maintaining the integrity and efficiency of the drainage system by preventing clogging and prolonging its lifespan.

- Q:How long do geotextiles last?

- Geotextiles can vary in lifespan depending on various factors such as the quality of the material, the specific application, and the environmental conditions they are exposed to. However, on average, geotextiles can last between 20 to 50 years.

- Q:How do geotextiles help with separation of different soil layers?

- Geotextiles help with the separation of different soil layers by acting as a barrier between them, preventing the intermixing of materials. They provide stability by allowing water to drain through while preventing the migration of fine particles, which helps in maintaining the distinct layers and preventing erosion.

- Q:I would like to make the beach bigger along the lake in our backyard. I am hoping to do it myself for my husband for father's day. I need suggestions on the best way to do this as a one women team.

- "Quilting fabric" is typically 100% cotton. Quilters prefer to use cotton over other fabrics. Sewing fabric can be any type of fabric ie: cotton, flannel, polyester, knit and others. Using "quilting fabric" is fine for a skirt as cotton is a good choice. I've sewn quite a few of my daughters clothes with it and it wears really well. The variety of patterns and colors is usually fantastic.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrid Roadbed Reinforcement with Low Elongation and Good Toughness

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords