Fiberglass Facing Mat for Road Protection - Wholesale Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Mat/ Fiberglass Mat for Road Protection Wholesale Price

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Technical Data:

| PRODUCT | TYPE | WEIGHT (G/M2) | WIDTH(MM) | ROLL WIEHGT (KG) | MOISTURE CONTENT(%) | BREAKAGE STRENGTH (N) | BINDER CONTENT(%) |

| EMC100 | E/C-GLASS | 100±30 | 200-3300 | 30-90 | < 0.2 | 170 | 8-13 |

| EMC150 | E/C-GLASS | 150±30 | 200-3300 | 30-90 | < 0.2 | 40 | 5-8 |

| EMC225 | E/C-GLASS | 225±30 | 200-3300 | 30-90 | < 0.2 | 60 | 4-7 |

| EMC300 | E/C-GLASS | 300±30 | 200-3300 | 30-90 | < 0.2 | 90 | 3-6 |

| EMC450 | E/C-GLASS | 450±30 | 200-3300 | 30-90 | < 0.2 | 120 | 2-5 |

| EMC600 | E/C-GLASS | 600±30 | 200-3300 | 30-90 | < 0.2 | 150 | 2-5 |

| EMC900 | E/C-GLASS | 900±30 | 200-3300 | 30-90 | < 0.2 | 180 | 2-5 |

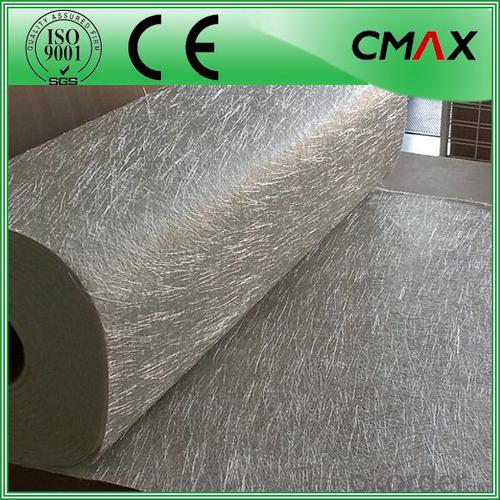

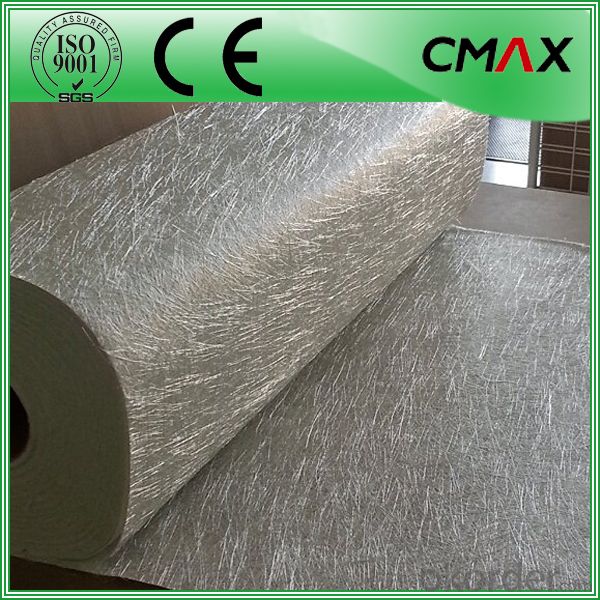

Products Shows:

Certificates:

- Q: Is it possible to recycle black fiberglass tissue in an environmentally friendly manner?

- <p>Yes, black fiberglass tissue can be recycled in a sustainable way. The process involves separating the fiberglass from other components, cleaning, and shredding it into smaller pieces. Recycled fiberglass can be used as a filler in new composite materials, reducing the need for raw materials and promoting sustainability. However, it's important to note that not all recycling facilities may accept black fiberglass due to the dye, which can complicate the recycling process. Proper disposal and recycling guidelines should be followed to ensure the material is handled correctly.</p>

- Q: Is it possible to use black fiberglass tissue in the manufacturing of furniture?

- <p>Yes, black fiberglass tissue can be used for furniture manufacturing. It is known for its strength, durability, and resistance to various environmental conditions, making it suitable for creating sturdy and long-lasting furniture. Fiberglass is often used in outdoor furniture and certain types of modern indoor furniture due to its versatility and ability to be molded into various shapes. However, it's important to consider the aesthetic appeal and the specific requirements of the furniture design when choosing to use black fiberglass tissue.</p>

- Q: This question asks for a comparison between black fiberglass tissue and other types of nonwoven fabrics, highlighting their differences.

- <p>Black fiberglass tissue is a type of nonwoven fabric made from black glass fibers, known for its high strength, heat resistance, and chemical stability. It's commonly used in construction, automotive, and aerospace industries. In contrast, other nonwoven fabrics can be made from various materials like polyester, polypropylene, or natural fibers, and they vary in properties. For instance, they may offer different levels of absorbency, breathability, and biodegradability. While black fiberglass tissue excels in durability and heat resistance, other nonwovens might be chosen for their softness, cost-effectiveness, or environmental friendliness.</p>

- Q: What is the production cost for black fiberglass tissues?

- <p>The cost to produce black fiberglass tissues varies and depends on several factors including the raw material costs, production scale, labor, energy consumption, and market demand. Fiberglass itself is made from silica sand, which is melted and spun into fine fibers. The addition of color, in this case, black, will add to the cost. However, without specific details on the production process, quantity, and current market prices for materials and labor, it's challenging to provide an exact figure. Generally, the cost can range from a few dollars to tens of dollars per square meter, but this is a rough estimate and actual costs may differ significantly.</p>

- Q: What is the tensile strength of black fiberglass tissue?

- <p>The tensile strength of black fiberglass tissue can vary depending on the specific type and manufacturing process. Generally, it ranges from 500 to 3000 MPa (or 72,500 to 435,000 psi). This high tensile strength makes it suitable for applications requiring high strength-to-weight ratios, such as in construction, automotive, and aerospace industries. It's important to note that the exact tensile strength should be obtained from the manufacturer's specifications for the specific product in question.</p>

- Q: Is it possible to utilize black fiberglass tissue in construction?

- <p>Yes, black fiberglass tissue can be used as a building material. It is known for its strength, durability, and resistance to various environmental factors, making it suitable for construction purposes. It is often used in the form of reinforced plastic or composite materials, enhancing the structural integrity of buildings and providing insulation. However, it's important to follow specific guidelines and regulations for its use in construction to ensure safety and effectiveness.</p>

- Q: The user is asking if they can use their old towels as a replacement for black fiberglass tissues.

- <p>While it might be tempting to repurpose old towels as a substitute for black fiberglass tissues, it's not advisable. Black fiberglass tissues are specifically designed for certain applications due to their unique properties, such as heat resistance and strength. Old towels, even if they are black, lack these specific characteristics and may not provide the same level of performance or safety. It's best to use materials as intended to ensure effectiveness and avoid potential issues.</p>

- Q: This question asks if there are any known allergies or sensitivities that people might have when using black fiberglass tissues.

- <p>While black fiberglass tissues are generally considered safe for use, some individuals may experience allergies or sensitivities. These can manifest as skin irritation, respiratory issues, or other allergic reactions. People with a history of allergies to fiberglass or similar materials should exercise caution. It's always recommended to consult a healthcare professional if you suspect an allergy or sensitivity to any product, including black fiberglass tissues.</p>

- Q: Explain the distinction between high-density and low-density black fiberglass tissue in a few sentences.

- <p>High-density black fiberglass tissue is characterized by a higher concentration of glass fibers per unit volume, resulting in greater strength and durability. This type is often used in applications requiring high mechanical resistance, such as in aerospace or automotive components. Low-density black fiberglass tissue, on the other hand, has fewer glass fibers per unit volume, making it lighter and more flexible. It is commonly used in applications where weight is a concern, such as in the electronics industry for insulation or in construction materials. The main differences lie in their mechanical properties, thermal conductivity, and applications.</p>

- Q: What are the recommended brands for black fiberglass tissue used in various applications?

- <p>There isn't a universally recommended brand for black fiberglass tissue as the choice often depends on specific application needs, quality requirements, and regional availability. However, some well-known brands in the composite materials industry that offer fiberglass tissues include Owens Corning, Hexcel, and SGL Group. These companies are recognized for their high-quality products and have a broad range of applications in industries such as aerospace, automotive, and construction. It's advisable to consider factors like product specifications, cost, and customer reviews when selecting a brand for black fiberglass tissue.</p>

Send your message to us

Fiberglass Facing Mat for Road Protection - Wholesale Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords