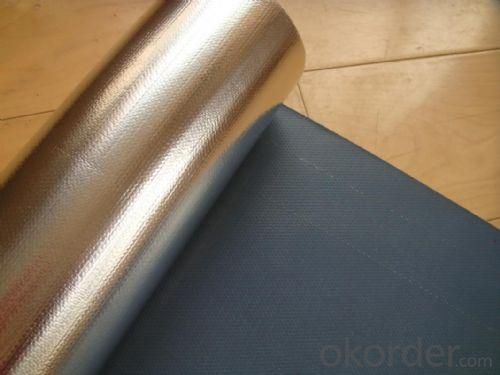

Fiberglass Fabrics Reinforced with High Quality Aluminium Foil

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of High Quality Fiberglass Fabrics Aluminium Foil:

The High Quality Fiberglass Fabrics Aluminium Foil is an engineering material weaved with glass fiber, which has the excellent merit such as anti-burns, anti-corrosion, stable-size, heat isolation, minimum elongated shrinkage, high intensity.It is widely used to make PVC fabric, water-proof material, free-proofing canvas and heat preservation materials.

Technical Data Sheet of High Quality Fiberglass Fabrics Aluminium Foil:

Fabric Count Warp×Fill(Per cm) | Yarn(SI)

| Thickness(mm) (Rreference Only) | Nominal Weight(g/m2) | Weight Tolerance(g/m2) |

23.6×18.5 | 5 11 1×0 5 11 1×0 | 0.053 | 46.8 | 45.1-48.5 |

23.6×23.6 | 5 11 1×0 5 11 1×0 | 0.056 | 52.9 | 51.5-54.2 |

19.3×16.5 | 7 45* 1×0 7 45* 1×0 | 0.149 | 164.1 | 157.7-170.5 |

18.1×17.7 | 7 45* 1×0 7 45* 1×0 | 0.140 | 1654.0 | 158.0-171.0 |

23.6×19.7 | 6 33 1×0 6 33 1×0 | 0.125 | 148.0 | 142.8-153.2 |

20.0×10.8 | 9 331×0 9 74 1×0 | 0.135 | 146.2 | 142.1-150.3 |

20.5×20.5 | 9 34* 1×0 9 34* 1×0 | 0.114 | 138.3 | 133.6-143. |

23.6×22.0 | 7 22 1×0 5 11 1×0 | 0.079 | 78.0 | 75.6-80.4 |

22.0×18.9 | 7 22 1×0 7 22 1×0 | 0.084 | 90.9 | 88.5-93.2 |

23.6×22.8 | 7 22 1×0 7 22 1×0 | 0.094 | 103.8 | 100.7-106.8 |

26.0×21.7 | 7 22 1×0 7 22 1×0 | 0.095 | 108 | 104.8-111.2 |

17.3×12.2 | 9 681×0 9 68 1×0 | 0.173 | 203.4 | 198.0-208.9 |

17.9×13.4 | 9 68 1×0 9 68 1×0 | 0.18 | 210.0 | 204.5-215.3 |

17.3×11.4 | 9 68 1×0 9 102* 1×0 | 0.201 | 232.3 | 226.5-238.0 |

17.5×7.9 | 9 68 1×0 9 136* 1×0 | 0.254 | 227.8 | 221.1-234.7 |

17.4×10 | 9 68 1×0 9 136* 1×0 | 0.250 | 260.0 | 255.2-265.3 |

- Q: Can fiberglass fabric be used for making insulation tape?

- Yes, fiberglass fabric can be used for making insulation tape. Fiberglass fabric is known for its excellent thermal insulation properties, as it is made from woven glass fibers that are resistant to high temperatures. These fabric tapes are commonly used in various industries, such as electrical, automotive, and aerospace, for insulating and protecting wires, cables, and pipes from heat and electrical currents. The fiberglass fabric is typically coated with a heat-resistant adhesive, which allows it to adhere to various surfaces and provide a secure insulation barrier. Overall, fiberglass fabric is a suitable choice for making insulation tape due to its thermal resistance, durability, and versatility.

- Q: Can fiberglass fabric be used for making flags and banners?

- Yes, fiberglass fabric can be used for making flags and banners. Fiberglass fabric is known for its durability, strength, and resistance to weather conditions, making it an ideal material for outdoor applications such as flags and banners. It is lightweight and flexible, allowing for easy handling and installation. Additionally, fiberglass fabric can be printed on using various techniques, ensuring vibrant and long-lasting colors on the flags and banners. Overall, fiberglass fabric is a reliable choice for creating flags and banners that are both visually appealing and durable.

- Q: What are the different finishes available for fiberglass fabric rolls?

- Some of the different finishes available for fiberglass fabric rolls include plain weave, leno weave, satin weave, twill weave, and herringbone weave. These finishes determine the pattern and texture of the fabric and can impact its strength, flexibility, and durability. Additionally, there are finishes that can be applied to fiberglass fabric rolls to enhance properties such as fire resistance, water repellency, and chemical resistance.

- Q: What is the width range of fiberglass fabric?

- The width of fiberglass fabric can differ based on the manufacturer and intended purpose. Typically, fiberglass fabric can be found in widths ranging from 30 to 60 inches. Certain specialized fabrics may be obtainable in wider widths, even surpassing 100 inches. To determine the available width choices for a specific fiberglass fabric, it is crucial to consult the designated manufacturer or supplier.

- Q: How is fiberglass fabric used in the production of insulation sheets?

- Fiberglass fabric is used in the production of insulation sheets as it acts as a reinforcing material. It provides strength and durability to the sheets, making them capable of withstanding various environmental conditions. Additionally, fiberglass fabric helps in maintaining the shape and structure of the insulation sheets, ensuring optimal thermal performance and energy efficiency.

- Q: Can fiberglass fabric be used for reinforcement in underground storage tanks?

- Yes, fiberglass fabric can be used for reinforcement in underground storage tanks. Its high strength, corrosion resistance, and durability make it a suitable material for reinforcing the structure of underground storage tanks, ensuring their structural integrity and preventing leaks or failures.

- Q: What are the different fiberglass fabric weaves for electrical insulation?

- There are several different fiberglass fabric weaves commonly used for electrical insulation. These weaves are designed to provide high electrical resistance and thermal stability, making them suitable for various applications in the electrical industry. One of the most commonly used weaves for electrical insulation is the plain weave. This weave consists of a simple over-under pattern, with each weft yarn passing alternatively over and under each warp yarn. The plain weave provides good strength and flexibility, making it suitable for applications where both electrical insulation and mechanical protection are required. Another common weave for electrical insulation is the satin weave. This weave is characterized by a more complex pattern, with multiple interlacing points between the warp and weft yarns. The satin weave provides a smoother surface, which can be advantageous in applications where the fabric needs to be in direct contact with conductive materials, as it reduces the risk of abrasion and damage. Twill weave is another popular option for electrical insulation. This weave is characterized by a diagonal pattern, with each weft yarn passing over two or more warp yarns before going under one. Twill weave fabrics offer higher strength and durability compared to plain weave fabrics, making them suitable for applications where increased mechanical protection is required. Lastly, there are specialty weaves available for specific electrical insulation needs. For example, leno weave is a type of weave that has a pair of warp yarns twisted around each weft yarn, resulting in a more secure fabric structure. Leno weave fabrics are often used in applications where high temperature resistance and dimensional stability are crucial. In conclusion, different fiberglass fabric weaves are used for electrical insulation depending on the specific requirements of the application. Plain weave, satin weave, twill weave, and specialty weaves like leno weave are all commonly employed to provide the necessary electrical resistance and thermal stability.

- Q: How do you do fiberglass fabric on latex paint?

- A small area of their own to do the next experiment.

- Q: Is fiberglass fabric resistant to insects?

- Yes, fiberglass fabric is generally resistant to insects. Fiberglass is made from woven strands of glass fibers, which insects are not attracted to or able to consume. Additionally, fiberglass fabric does not provide a suitable environment for insects to nest or breed, as it is non-porous and does not retain moisture. This makes it a popular choice for insect screens and protective covers, as it effectively keeps insects out without the need for chemical insecticides. However, it is important to note that while fiberglass fabric itself is resistant to insects, the seams and openings in the fabric may still allow insects to enter. Therefore, proper installation and maintenance are necessary to ensure complete insect resistance.

- Q: How is fiberglass fabric used in the production of windbreakers?

- Windbreakers often incorporate fiberglass fabric due to its unique properties that make it suitable for this purpose. Lightweight, durable, and able to withstand harsh weather conditions, fiberglass fabric offers all the qualities needed for windbreaker production. To reinforce windbreakers, fiberglass fabric is commonly used as a material. It is incorporated into specific areas like the shoulders, elbows, or hood to provide extra strength and durability. Acting as a protective layer, fiberglass fabric prevents tears or rips in these high-stress areas, resulting in a longer-lasting and more efficient windbreaker. The thermal insulation properties of fiberglass fabric are also well-known. Windbreakers are designed to keep wearers warm and comfortable in windy or chilly weather, and fiberglass fabric plays a significant role in achieving this goal. By acting as a barrier against wind, it prevents it from penetrating the fabric and stealing body heat. This insulation property helps retain the warmth generated by the body, ensuring the wearer stays cozy even in harsh weather conditions. Furthermore, the lightweight nature of fiberglass fabric is essential for windbreaker production. Windbreakers are typically designed to be portable and easy to carry, making them ideal for outdoor activities like hiking or camping. With fiberglass fabric being lightweight, it ensures the windbreaker remains comfortable and doesn't add unnecessary bulk to the wearer. Lastly, fiberglass fabric is water-resistant, which is another crucial feature for windbreakers. It repels water and keeps wearers dry during light rain or drizzles. This property is particularly important for outdoor enthusiasts or individuals engaging in activities in damp or unpredictable weather conditions. In conclusion, fiberglass fabric is utilized in windbreaker production due to its reinforcement capabilities, thermal insulation properties, lightweight nature, and water resistance. These qualities make fiberglass fabric an excellent choice for ensuring durability, comfort, and protection from wind and other weather elements in windbreaker designs.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1964 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 200,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Fiberglass Fabrics Reinforced with High Quality Aluminium Foil

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords