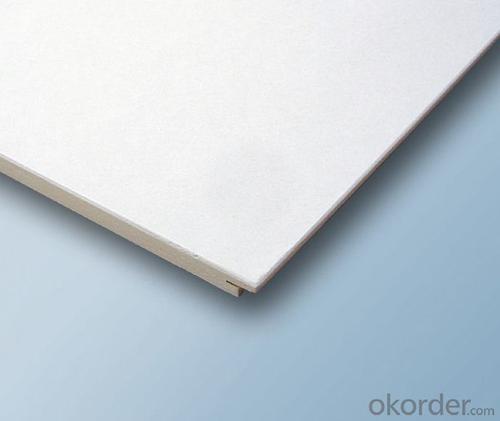

Fiberglass acoustic ceiling tile acoustic wall ceiling tile 60x60 30x120 60x120cm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

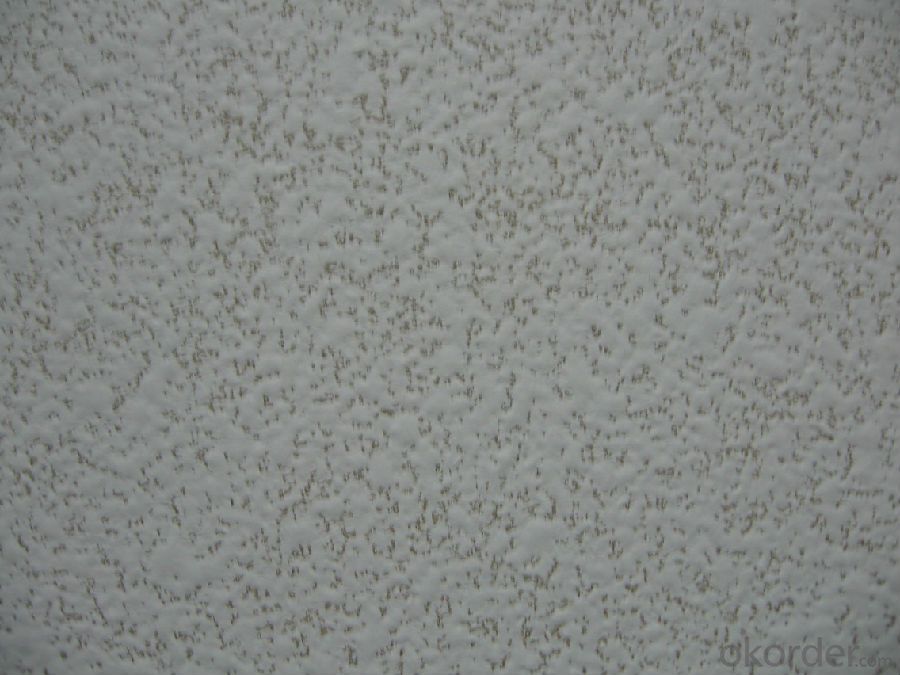

Fiberglass acoustic ceiling tile acoustic wall ceiling tile

Specifications:

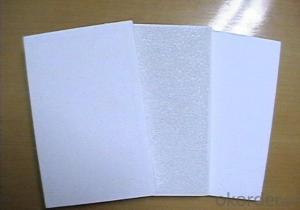

Main Material: Fiberglass wool

Density: Standard 100kgs/m3

Thickness: 15mm,20mm, 25mm and etc.

Size: 600*600mm,600*1200mm and etc.

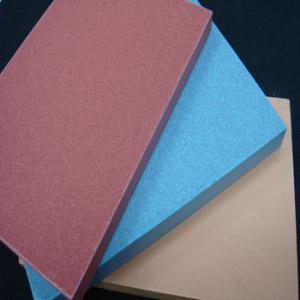

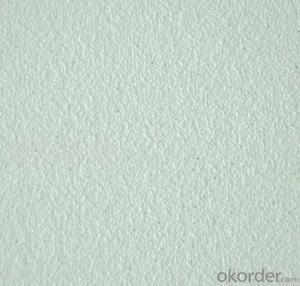

Textures: White painted, Mix Acoustic, White Spray, BlackSpray

Edge: Square, Tegular for 15/24 grids, Concealed

Black spray White spray

Mix Acoustic White painted

Fiberglass acoustic ceiling tiles decoration material

Quick Detail:

Non-combustible;

No sagging, warpping or delaminating;

Green building material;

Excellent sound absorption;

With different pattern available;

Applications:

Halls, Classrooms, Offices, Shopping centers, etc.

Competitive Advantages:

Fire-resistant;

Thermal-insulation;

Humidity-resistant;

Cleanability;

Environmental;

Elegant;

Safety and Convenience;

- Q: Bathroom waterproof well, why would water leakage?

- Toilet sewer mouth and floor drain around the water will be the corner, there may be infiltration along the water pipe. And then there is the possibility of tiling when the accidentally destroyed the waterproof layer. You paste the floor tiles in the brick after the tile on a layer of plugging the spirit can be

- Q: What is foam insulation

- Phenolic foam or internationally recognized building ranks among the most promising new insulation materials. Because this new material and the usual polymer resin by adding flame retardant materials are essentially different from the fire does not burn, do not melt, it will not distribute toxic smoke, and has a light, non-toxic, no Corrosion, insulation, energy saving, noise, cheap, etc., and do not have freon foam, no environmental pollution, good processing, construction convenience, its comprehensive performance is a variety of insulation materials can not be compared. Common in hotels, apartments, hospitals and other senior and high-rise building central air-conditioning system insulation (Hong Kong's senior building central air-conditioning system has been the majority of use of phenolic foam). Cold storage and cold storage for industrial and other industrial pipelines and equipment, insulation, building partitions, facade composite panels, ceiling ceilings, sound-absorbing panels and other controversial advantages, to solve the other organic materials, fire performance is not Ideal, and inorganic materials, water absorption, easy "condensation", the construction of skin itching and other issues, is the air conditioning system, the best of the third generation of electrical insulation materials.

- Q: Bought a house about a year ago, and the basement ceiling is stuffed with fiberglass insulation. It's warm in the basement, especially the room where the furnace is, but we hardly ever use it.I'm wondering if all that insulation is trapping the heat the furnace gives off while it runs, preventing it from rising upstairs? Would it be worth removing it myself or just let it all stay in the ceiling? If you recommend removal what's the best way to dispose of it?Thanks!

- i would just leave it for the sound barrier alone but thats just me, it really shouldnt have any bearing on the heat for the above floor, unless the floor above has radiant heating tubes underneath than you should definatelly leave it in but other wise dont worry about it .

- Q: What is the optical fiber made of material?

- The main ingredient in quartz stone made of silicon oxide! The

- Q: Epoxy resin when the ratio of curing agent than the high proportion of what impact? What is the impact of low. What is the reason for hardening after curing?

- Do not be high outrageous / do not break out of line like Kazakhstan / pure resin ratio is 2 to 1 /

- Q: I was replacing a bathroom fan and the new bathroom fan is bigger than the old one. I took out the old one. Then I used a pencil and traced around the new fan. Then I used a reciprocating saw for the first time and got a little crazy with it. Now the hole is slightly too big and when I put the grill cover on the fan, I can see the hole. I'm not sure what to do now. I still got old pieces of the ceiling. Maybe I can do something with it?

- It sounds like when you put the fan in you can see holes around it. If that is correct then get some cardboard and wrap around the fan two or three times around the fan where it fits through the hole. So later when it is removed it give the correct gap around the fan fit to the hole.Now you should be able to secure the fan in place but not up tight to the roof, so you can still get plaster into the gap. Then get some plaster filler. you can get it from hardware store. And with a scraper that is used for plaster fill the gap. Let it dry. You then take the fan out and then remove the cardboard and discard. With the cardboard out their should be just the right amount of gap for the fan to fit back in snuggle and perfect. Use just enough cardboard as you think will do the job. The plaster also sticks to the card board and not the fan housing. You can also rap some Glad Wrap around the cardboard on the out side and it will pull away from the plaster easier when it is dry.Then sand, then you may need that repair with the fiber netting that sticks to it, to strengthen the around the hole. ( buy from hardware. just ask them and they will know. ) stick some of that on to strengthen it and put more plaster on. Let dry, sand and paint. If you google wall plastering repairs you should be able to get some demonstration on how to repair walls with holes so it will show you how to use the mesh to repair. It is not really very difficult. Good luck.

- Q: I'm thinking of adding a ceiling to my porch to create an insulation space (the roof alone radiates a lot of direct heat in the summer; the porch otherwise is open) between it and the roof (corrugated fiberglass) but I'd like to still be able to see the roof as I've already painted the roof's interior and like how it contrasts with the supporting frame's color.I'm also looking to paint the exterior of the roof to better waterproof it (some leaks where previous owner screwed it in) and to better reflect light to further reduce heat. Any suggestion on paint or would it be better to just replace the roof entirely with better material? Thanks!

- There are many ways you could go. Yes, you can use the plexi to create insulation space. The best insulation is dead air. That is, air that cannot circulate and move around. The key to using it will be using something to seal it tight, a clear silicone caulk, perhaps. They make a special glue for it, you could make smaller areas to help keep air movement down with strips inside the ceiling area to form the pockets of air. Think bubblewrap, only solid. Probably caulk or glue on the joists is good enough. As for the exterior, fiberglass is extremely difficult to get paint to stick to, unless you use the gel coat stuff made for it. Maybe there is a good primer to make it take paints. If possible, paint it with the same stuff made for mobile home roofs, tho I don't know how well it will stick to fiberglass, it does fine on the metal roof of a mobile home. The stuff I'm talking about is available in only a few colors, white, silver, gray, and black. It's thick, like tar, but not tar. If you use the silver or white, it should help keep down the heat, after all, that's what it's designed for. It also has insulation and leak sealing properties. If you have a good cheap supply of the plexi, you could also put plexi over it for sealing, but before you do, you could use window tint on it, the kind that looks like a mirror on one side, and is dark on the other. put the mirror towards the sun. If you put your mind to it, there are probably many many ways to get done what you need to do. Maybe there's some way to use recycled materials.

- Q: Does the fiberglass ceiling do the ceiling?

- Long mineral wool ceiling to introduce advanced Japanese production technology, the use of European green standards testing, monitoring, the introduction of the production of European-style Italian light steel keel production system.

- Q: I read that fiberglass insulation that has a backing sheet should have the backing sheet toward the heated space. The insulation in the basement ceiling has the backing sheet toward the inside of the basement not the bottom of the floor above. Does this trap moisture and cause a lot of harm or does it just make the insulation less effective? Do I need to take it all down and start with new insulation? Should I just add a new layer over the top what is there?

- Insulation in a finished basement ceiling is for noise, rather than thermal. Ideally, it will not have a vapor barrier, which is what the paper is. You should use unfaced batts, and use retainers to keep it in place. You can leave it how you have it, however, as long as there isn't a huge difference between the temps of the basement and the upstairs. If the area is not finished or heated, such as a crawlspace, there is a very real possibility that moisture could collect in the insulation, leading to mold issues. The insulation in that scenario MUST be installed with the vapor barrier up. That is NOT just for walls. Hope this helps.

- Q: Renovation of living room wall with steel bricks

- That is too wasteful, and now is not popular. I think it is good with a big mud, both environmentally friendly and beautiful. The Also save money

Send your message to us

Fiberglass acoustic ceiling tile acoustic wall ceiling tile 60x60 30x120 60x120cm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords