F Green Toughened glass Security features Hollow glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Provide QAIC/CN attestation

Provide ISO 9001-2008 CCC attestation

Provide super quality and competitive price

Tempered, toughened glass is heated to the temperature that near soft point, the surface resulting from the rapid cooling homogeneity has powerful compressive stress, the glass is double increase in all mechanical performance indexes. The surface stress value for tempered glass is more than 90Mpa and 24-69Mpa for the semi-tempered or toughened glass.

The feature of tempered glass:

High intensity: The bending strength of tempered glass is 3-4 times than common glass and the shock strength is 6-7 times than common glass.

Heat stability: Tempered glass has good thermal stability can withstand a range in 300 ℃temperatures, which is 3 times than common glass.

Security: Because of the stress layer of tempered glass, thus has strong shock resistance, make its not easy to damage, and it will not cause greater harm to human body when the broken glass after obtuse angle formed by small particles.

Toughened glass is also called heat enhancement or tempered glass, its strength is 1.5 to 2 times of ordinary annealed glass, thermal stability is twice as common annealed glass, toughened glass of flatness is approach to ordinary annealed glass and far superior to toughened glass, its biggest advantage is that there is no explosive's ills, but once causing damage, it still produces larger pieces and after its damage easily hurt the body, but its security is better than ordinary annealed glass.

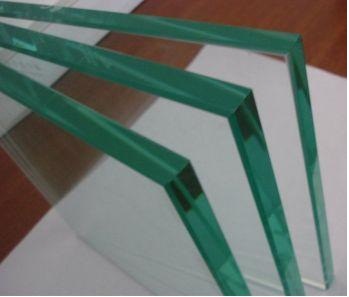

Maximum processing size: 11000 mm * 3000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 4 mm to 25 mm

Insulating Glazing

A. All glass can be processed before assembly

B. Glass transfer onto the glass loading machine

C. Edge coating removing of coated glass

D. Wash and clean strictly

E. Automatic bending for air spacer

F. Automatic molecular sieve filling

G. Automatic butyl rubber applying

H. Automatic framing

K. Automatic scanning positioning

L. Automatic double sealing

M. Transfer by sucking disc

N. Conner finishing

O. Glass on the shelves till solidification

P. Customized wooden cases according to the size of glass

Q. Transfer the glass into the specific wooden cases

R. Leading Time:10 days for an average area of 1000 square

meters tempered glass

S. Trade terms: FOB and CIF.

T. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

U. The container loading after the package checking

- Q: Will the frame glass curtain wall, each frame size 1615 * 965mm, the use of 6 PCT tempered glass is dangerous?

- According to the curtain wall in the coastal side, 1615 * 965mm specifications 6mm tempered glass stress calculated value is 31N / mm ^ 2, and its allowable value is 84N / mm ^ 2, the calculated deflection is 9mm, and its allowable value is short edge 1/60 (ie 965/60 = 16mm). So it is safe enough. Glass shop that glass is too thin, I guess the reason: ah: they give you the glass is not steel, Oh, so pay attention.

- Q: Tempered glass and ordinary glass technology and raw materials What is the difference in detail Thank you

- General material the same. Tempered glass is the ordinary flat glass or float glass in a specific process conditions, quenching or air-cooled quenching method from the processing, has "tempered glass" entry.

- Q: Construction of the provisions of double glass

- Your description is too rough, the glass must be the specifications (such as: 5mm white film + 6A +5 mm white, 5mm white + 9A +5 mm white, 5mm white + 12A +5 mm white, etc.) to others There are profiles and wall thickness, need to be tempered glass in the deepening of the design marked out! (Do not write to understand when they are very passive)

- Q: any home remedies to get the buildup on glasses off? i use jet dry and it's suppose to help but nothing does..it's nasty!

- Soak them in a sink full of water with about 1/4 c of vinegar, for 20 mins, then wash again. If it doesn't come off, or gets worse, it could be etching (where the glass actually gets eaten away and creates a dull surface). If the glasses are etched, you may just need to get new ones...

- Q: how to clean scum build up on glass shower doors?

- Automotive Chrome & Glass cleaner works extremely well, but takes a lot of effort.

- Q: What is the difference between home insulation film and car insulation film?

- Home reflective film point, good heat insulation, automotive reflective film can not be too much, otherwise the traffic police will let the tear

- Q: In Sims 2 castaway for PS2 where can i find fine sand? I need it to build glass.?

- Fine Sand is found on Crystal Island(the 4th island). You need a lot of it to make glass and you need to use the Forge in the temple to craft the glass. You also can get Fine Sand in other ways: 1. Get from Chimp... ask your chimp to get resources, but it's hard to get this way. 2. Get from Crew Mates, sign job most of your tribe as Resources Collectors. If you lucky they will bring it with them.

- Q: I am planning a winter project, we have several nice lakes here. Any ideals?

- IN FUTURE ALL SHIPS WILL BE BUILD WITH SPLASTIC BECAUSE THE SHIP WILL NOT SINK AND THEREFORE ALL MANKIND WILL BE SAVED. TITANIC THOUGHT US A BITTER LESSON. GOD BLESS AMERICA.

- Q: can i build a tank 2000x500x400mm with braces with 5mm thick glass?

- theoretically okorder /... visit these sites where you can find the safety factor with 5 mm but really 5mm is a nothing thickness as your width is 20 inch which is too much pressure on side glass

- Q: Curtain wall classification of building curtain wall

- Building curtain wall is composed of supporting structural system and the panel can be relative to the main structure of a certain displacement ability, but does not share the main structure of the load and the role of the building outside the envelope or decorative structure. (2) the whole glass curtain wall (2) the whole glass curtain wall (2) the whole glass curtain wall (2) the whole glass curtain wall (2) the whole glass curtain wall (2) 3) point support glass curtain wall 2. metal curtain wall 3. stone curtain wall 4. man-made sheet curtain wall 5. combination curtain wall (b) according to the curtain wall construction method classification is divided into: 1. unit curtain wall 2. component curtain wall (three) Double curtain wall 2. Light curtain wall

Send your message to us

F Green Toughened glass Security features Hollow glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords