EPDM Pond Liner Manufacturer with 15-year Experience

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction:

This waterproof coiled material is of high elasticity with best performance among high polumer

waterproof coiled material in the world.It is also the most typical one in the world.Waterproof coiled material made of ternary ethylene-propylene rubber is produced withthe use of the most advanced contiuous extrusion and vulcanization technology and related equipments which are specially designed for production of such product.It is good in compactness,without bubble and performance difference in length and breadth,perfomances reach or exceedthe demands of GB18173.1-2000 standard.

2. Product Specification:

There are two installation ways.one is full sticking,the other is hot welding.

Thick | 1.0mm,1.2mm,1.5mm,2.0mm,3.0mm or others |

Width | 1m to 4m |

Length | 20m |

Model | EPDM, EPDM with fabric |

3. Technical Sheet for EPDM Waterproof Membrane:

Number | Item | Unit | Value | |

1 | Size Variation | Thichness | % | ±10 |

Width | % | ±1 | ||

Length | % | Allowed negative | ||

2 | Breaking tensile strength at normal temperature | Mpa | ≥7.5 | |

Breaking tensile strength at 70°C | Mpa | ≥2.3 | ||

3 | Breaking elongation at normal temperature | % | ≥450 | |

Breaking elongation at -20°C | % | ≥200 | ||

4 | Tear strength | KN/m | ≥25 | |

5 | Impermeability(30min) | * | 0.3Mpa no leakage | |

6 | Bending at low tempreture | °C | ≤-40 | |

7 | Stretch tensor at heating | Elongate | mm | ≤2 |

Shrink | mm | ≤4 | ||

8 | Air oven aging(80°C×168h) | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥70 | ||

9 | Anti-alkali | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥80 | ||

10 | Nuture weathing at manual simulation | Tensile strength at break retained | % | ≥80 |

Elongation at break retained | % | ≥70 | ||

4. Product Application:

EPDM waterproof membranes form an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway & tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke and subway.

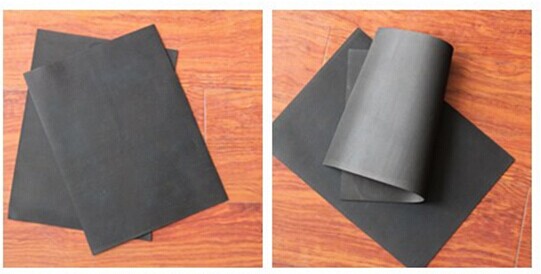

5. Some photos:

- Q: Can a waterproofing membrane be used on parking garages?

- Indeed, utilizing a waterproofing membrane is highly recommended for parking garages to safeguard the structure against water damage. Parking garages are exposed to varying weather conditions, including rain, snow, and ice, which can lead to water infiltration through cracks, joints, or porous concrete. This infiltration can result in corrosion of reinforcing steel, degradation of concrete, and compromise the overall integrity of the structure. A waterproofing membrane serves as a specialized barrier system designed explicitly to impede water penetration and shield the underlying structure. Typically composed of materials like modified bitumen, PVC, or liquid applied coatings, the flexible membrane is applied to the surface of the parking garage, delivering a seamless and resilient waterproof barrier. Using a waterproofing membrane for parking garages offers numerous advantages. Firstly, it significantly prolongs the lifespan of the structure by shielding it from water-induced deterioration. Secondly, it upholds the structural integrity of the garage by preventing reinforcing steel corrosion, which can gradually weaken the structure. Furthermore, a waterproofing membrane maintains a dry and secure environment within the parking garage, thereby reducing the risk of slip and fall accidents. It is crucial to consider the specific requirements and conditions of the parking garage when selecting the appropriate waterproofing membrane. Factors such as the type of parking garage (underground, above ground, or rooftop), traffic volume, presence of vehicular fluids, and climate should all be taken into account when choosing the suitable waterproofing membrane system. In conclusion, to safeguard parking garages from water damage, extend their lifespan, and ensure a safe environment for users, the use of a waterproofing membrane is both viable and essential.

- Q: Can a waterproofing membrane be used on precast iron surfaces?

- Yes, a waterproofing membrane can be used on precast iron surfaces. A waterproofing membrane is a thin layer of material that is applied to a surface to prevent the penetration of water or moisture. It can be applied to a variety of surfaces, including precast iron surfaces. The waterproofing membrane acts as a barrier, preventing water from seeping into the precast iron and causing damage such as rust or corrosion. This can be particularly important in areas where the precast iron surface is exposed to water or moisture, such as in outdoor installations or areas with high humidity levels. The use of a waterproofing membrane on precast iron surfaces can help to extend the lifespan of the structure and maintain its structural integrity.

- Q: Are waterproofing membranes resistant to seawater?

- Yes, waterproofing membranes are generally resistant to seawater. They are designed to provide a barrier against water infiltration, including salty seawater, and are commonly used in various marine applications.

- Q: Can a waterproofing membrane be used for residential buildings or homes?

- Yes, a waterproofing membrane can be used for residential buildings or homes. It is commonly used in basements, bathrooms, and other areas prone to water damage to prevent moisture infiltration and protect the structure from potential water leaks or flooding.

- Q: Can a waterproofing membrane be used on sloped surfaces?

- Yes, a waterproofing membrane can be used on sloped surfaces. In fact, it is highly recommended to use waterproofing membranes on sloped surfaces to prevent water infiltration and potential damage. The membrane is designed to create a barrier against water, and when properly installed, it can effectively protect sloped surfaces such as roofs, balconies, or even retaining walls. The membrane is typically flexible and can conform to the shape of the slope, ensuring full coverage and a watertight seal. Additionally, some waterproofing membranes have additional features like self-adhesive properties or reinforcement layers specifically designed for sloped surfaces, further enhancing their effectiveness. Overall, using a waterproofing membrane on sloped surfaces is an excellent way to ensure long-term protection against water damage.

- Q: Are there any specific maintenance requirements for a waterproofing membrane?

- Yes, there are specific maintenance requirements for a waterproofing membrane. Regular inspections should be conducted to check for any signs of damage or deterioration, such as cracks or leaks. Any debris or standing water should be promptly removed to prevent potential damage. Additionally, it is important to follow the manufacturer's guidelines for cleaning and maintenance, which may include periodic cleaning with mild detergents and avoiding the use of harsh chemicals or abrasive cleaning tools.

- Q: Can a waterproofing membrane be used for basements?

- Yes, a waterproofing membrane can be used for basements. In fact, it is one of the most effective solutions for preventing water infiltration and moisture damage in basements. A waterproofing membrane is a thin layer of material that is applied to the exterior walls and/or floors of a basement to create a barrier against water. It is designed to withstand hydrostatic pressure, which is the force exerted by water against the walls and floors. By installing a waterproofing membrane, you can significantly reduce the risk of water damage, mold growth, and structural problems in your basement. It is important to note that proper installation and maintenance of the membrane are crucial for its effectiveness, so it is recommended to consult with a professional waterproofing contractor for the best results.

- Q: Are waterproofing membranes resistant to gasoline?

- Waterproofing membranes, in general, display resistance towards gasoline. These membranes are chemically resistant and capable of enduring exposure to diverse chemicals, which includes gasoline. Nevertheless, it is crucial to acknowledge that the extent of resistance may differ depending on the particular membrane type and its composition. Certain membranes may provide superior resistance to gasoline compared to others. Furthermore, extended exposure to gasoline can potentially harm or deteriorate the membrane over time, hence it is always advised to take essential precautions and avoid prolonged contact with harsh chemicals.

- Q: Can a waterproofing membrane be used in bathrooms or showers?

- Yes, a waterproofing membrane can be used in bathrooms or showers. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water damage and leakage. A waterproofing membrane acts as a barrier that prevents water from penetrating through the walls, floors, and other surfaces in the bathroom or shower. It is typically applied before tiling or finishing the surfaces, providing an extra layer of protection against moisture and ensuring that the underlying structure remains dry. This not only helps to prevent mold and mildew growth but also prolongs the lifespan of the bathroom or shower.

- Q: Can a waterproofing membrane be used for pond or pool applications?

- Yes, a waterproofing membrane can be used for pond or pool applications. Waterproofing membranes are designed to provide a barrier against water penetration, making them an ideal choice for sealing ponds and pools. These membranes are typically made from synthetic materials such as PVC, EPDM, or TPO, which are highly resistant to water and UV rays. They are available in various thicknesses and can be customized to fit the specific dimensions of the pond or pool. Additionally, waterproofing membranes are durable and flexible, allowing them to withstand the constant exposure to water and the movement of the underlying substrate. Overall, using a waterproofing membrane for pond or pool applications can help prevent leaks, prolong the lifespan of the structure, and ensure a safe and enjoyable water environment.

Send your message to us

EPDM Pond Liner Manufacturer with 15-year Experience

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords