Brand Packaging Tape - Eco-Friendly PVC Electrical Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Environmentally Friendly PVC Electrical Tape

A thin premium grade plasticized PVC film coated with an aggressive rubber based adhesive with good characteristics. It is highly conformable and unaffected by most chemicals and moisture

Application of Environmentally Friendly PVC Electrical Tape

Electric insulation below 600V; Insulating wrapping of electric wires and cables; Marking of electric wires and cables; Can be used indoors and out door

Available Size of Environmentally Friendly PVC Electrical Tape

Paper Core ID: 76mm; 56mm; 38mm; 32mm

Jumbo Roll size: 1250mm x 33m

Cut roll size: 19mm x 10m; 19mm x 20m or as per customer's requirement

Cut rolls: Nine rolls in one plastic bag, placed in cartons, with or without pallet

Packing of Environmentally Friendly PVC Electrical Tape

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

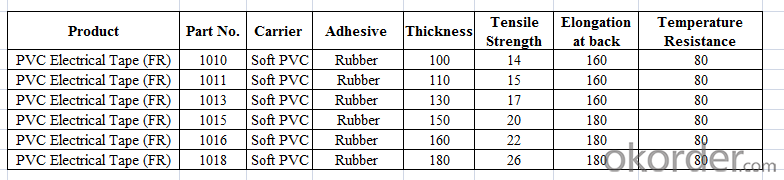

Technical Data of Environmentally Friendly PVC Electrical Tape

Product Show of Environmentally Friendly PVC Electrical Tape

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

- Q: How do I prevent packaging tape from wrinkling?

- To prevent packaging tape from wrinkling, there are a few things you can do: 1. Use a tape dispenser: A tape dispenser helps ensure a smooth application of tape, reducing the chances of it wrinkling. It also provides better control while taping, making it easier to keep the tape straight and tight. 2. Apply the tape with tension: When applying the tape, pull it tightly as you stick it down. This helps prevent any slack or loose areas that could cause wrinkling. Be careful not to stretch the tape too much, as it may lose its adhesive properties. 3. Use the right type of tape: Different types of packaging tape have different adhesive properties and thicknesses. Choosing a high-quality tape specifically designed for packaging can help minimize wrinkling. Additionally, consider using a tape with reinforced fibers for added strength and resistance to wrinkling. 4. Ensure a clean surface: Before applying the tape, make sure the surface is free from dust, dirt, or any other debris. These particles can cause the tape to wrinkle or not adhere properly. Clean the surface thoroughly and dry it before taping. 5. Avoid extreme temperatures: Packaging tape can be sensitive to temperature changes, which may lead to wrinkling. Avoid using the tape in extremely cold or hot environments. If possible, store the tape in a controlled temperature area before use. 6. Apply pressure: After applying the tape, run your hand or a roller over it to ensure good adhesion. This helps smoothen out any potential wrinkles or bubbles and ensures that the tape is securely attached. By following these tips, you can significantly reduce the chances of packaging tape wrinkling, resulting in a neater and more secure package.

- Q: Can packaging tape be used for sealing packages with electronics or electrical components?

- Yes, packaging tape can be used for sealing packages with electronics or electrical components. However, it is important to note that not all packaging tapes are suitable for this purpose. When selecting a packaging tape for sealing packages with electronics or electrical components, it is recommended to choose an anti-static or ESD (electrostatic discharge) safe tape. These tapes are specifically designed to prevent static electricity from damaging sensitive electronic components during shipping or handling. Using regular packaging tape without anti-static properties may pose a risk of static discharge that could potentially damage the electronics or affect their performance. Therefore, it is crucial to consider the specific requirements of the electronics or electrical components being packaged and select an appropriate tape to ensure their protection.

- Q: Is packaging tape safe to use on delicate items?

- Packaging tape can be safe to use on delicate items, but it depends on the type of tape and how it is applied. Some packaging tapes are specifically designed for delicate items and have features like low tack adhesive or gentle release properties, which minimize the risk of damage. These tapes are often transparent and are commonly referred to as "low-tack" or "gentle" tapes. When using packaging tape on delicate items, it is important to ensure that the tape is applied carefully and securely, without excessive force or pressure. It is recommended to test the tape on a small, inconspicuous area of the item first to ensure that it does not cause any harm or leave any residue. Additionally, it is advisable to wrap delicate items with protective materials like bubble wrap or tissue paper before applying the tape, as this provides an extra layer of cushioning and protection. If you are uncertain about the safety of using packaging tape on a specific delicate item, it is always best to consult with the manufacturer or seek professional advice. They can provide guidance on the most appropriate packaging materials and methods to ensure the safety of your delicate items during transit or storage.

- Q: Does packaging tape come in different widths for different applications?

- Packaging tape indeed comes in a variety of widths to suit different purposes. You can find packaging tape in a range of widths, starting from as little as 0.75 inches and going up to 3 inches or even wider. The width you choose depends on the specific task at hand and the size of the package you are sealing. When dealing with lighter packages or sealing small boxes or envelopes, it is common to opt for narrower widths. Conversely, wider tape is frequently used when dealing with heavy-duty or larger boxes that require added strength and security. With the availability of different widths, users can easily select the most suitable tape size based on their unique packaging requirements.

- Q: Can packaging tape be used for sealing camping or outdoor gear?

- Yes, packaging tape can be used for sealing camping or outdoor gear. Packaging tape is designed to securely seal boxes and packages, providing a strong and durable seal. It can be used to seal tears or openings in tents, sleeping bags, backpacks, or any other camping gear made of fabric. However, it is important to note that packaging tape may not be as effective as specialized outdoor gear repair tape, which is specifically designed to withstand harsh outdoor conditions and provide a more durable and long-lasting seal. Additionally, when using packaging tape for sealing camping gear, it is recommended to clean and dry the area before applying the tape to ensure a proper bond.

- Q: For the moment the yellow rubber stamp [] how to use paper and pen, pen parts packaging tape?

- How to paste it on how to post, usually a lap bar

- Q: How does packaging tape perform on recycled or eco-friendly packaging materials?

- Packaging tape generally performs well on recycled or eco-friendly packaging materials. Most packaging tapes are designed to adhere to a variety of surfaces, including paper-based or biodegradable materials commonly used in eco-friendly packaging. However, it is always recommended to check the compatibility of the specific tape with the packaging material to ensure optimal adhesion and sustainability.

- Q: Does packaging tape come in different colors for organization purposes?

- Yes, packaging tape does come in different colors for organization purposes. Many companies offer packaging tape in various colors such as red, blue, green, yellow, and black. These different colors can be used to categorize and organize different types of packages or to differentiate between shipments going to different destinations. It can be particularly useful in warehouses or shipping departments where multiple packages need to be identified and sorted easily. Additionally, colored packaging tape can also be used for decorative purposes, such as gift wrapping or creating visually appealing packaging for retail products.

- Q: How do I prevent packaging tape from leaving a sticky residue?

- One way to prevent packaging tape from leaving a sticky residue is to use a high-quality tape that is specifically designed for packaging. Look for tape that is labeled as "residue-free" or "low-tack." Additionally, try not to leave the tape on the surface for an extended period of time as it can increase the chances of residue forming. When removing the tape, do it slowly and at a 45-degree angle to minimize any residue left behind. If there is still some residue, you can use rubbing alcohol or adhesive remover to gently wipe it off.

- Q: Is packaging tape safe to use on mirrors?

- In general, using packaging tape on mirrors is considered safe. This tape is known for its strength and adhesive properties, which are intended to effectively hold objects in place. Nevertheless, it is crucial to consider the specific type of packaging tape being used, as it can impact the tape's safety when applied to mirrors. Opting for clear packaging tapes or tapes specially made for glass surfaces is typically the wisest choice in order to prevent any potential harm or residue on the mirror. Moreover, it is advisable to conduct a preliminary test on a small, inconspicuous area of the mirror to ensure proper adhesion and to avoid any potential damage.

Send your message to us

Brand Packaging Tape - Eco-Friendly PVC Electrical Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords