Eco Friendly PVC Electrical Tape Packed with Bags and Carton

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of PVC Electrical Tape Packed with Bags and Carton

A thin premium grade plasticized PVC film coated with an aggressive rubber based adhesive with good characteristics. It is highly conformable and unaffected by most chemicals and moisture

Application of PVC Electrical Tape Packed with Bags and Carton

Electric insulation below 600V; Insulating wrapping of electric wires and cables; Marking of electric wires and cables; Can be used indoors and out door

Available Size of PVC Electrical Tape Packed with Bags and Carton

Paper Core ID: 76mm; 56mm; 38mm; 32mm

Jumbo Roll size: 1250mm x 33m

Cut roll size: 19mm x 10m; 19mm x 20m or as per customer's requirement

Cut rolls: Nine rolls in one plastic bag, placed in cartons, with or without pallet

Packing of PVC Electrical Tape Packed with Bags and Carton

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

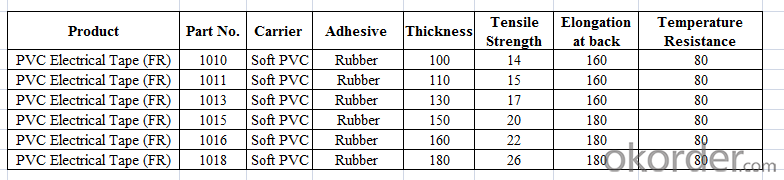

Technical Data of PVC Electrical Tape Packed with Bags and Carton

Product Show of PVC Electrical Tape Packed with Bags and Carton

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

- Q: Can scotch tape wrap wires?

- No, it's not safe. We should use electrical tape. We have a lot of transparent tapes for the last time

- Q: Is packaging tape resistant to extreme pressure or weight?

- Yes, packaging tape is designed to be resistant to extreme pressure or weight. It is specifically made to securely hold and seal packages, ensuring they stay intact even when subjected to heavy loads or pressure.

- Q: Is packaging tape heat resistant?

- Indeed, packaging tape typically exhibits heat resistance. The composition of most packaging tapes involves materials like polypropylene or acrylic, which possess elevated melting points and can endure extreme temperatures. Thanks to this heat resistance, packaging tape serves diverse purposes, such as sealing boxes and packages that may encounter heat during transportation or storage. Nevertheless, it is crucial to acknowledge that the heat resistance of packaging tape may fluctuate based on the tape's brand and quality. Hence, it is advisable to review the product specifications or seek guidance from the manufacturer to guarantee the tape's appropriateness for the desired utilization and temperature circumstances.

- Q: Can packaging tape be used for sealing glass bottles?

- Indeed, glass bottles can be sealed using packaging tape. Nevertheless, it is crucial to acknowledge that packaging tape is not explicitly crafted for the purpose of sealing glass bottles; hence, it may not offer the equivalent level of robustness and air-tightness as dedicated bottle sealing techniques. Moreover, the adhesive on packaging tape may fail to adhere effectively to glass surfaces, potentially resulting in leakage or breakage. To guarantee optimal outcomes, it is advisable to employ appropriate bottle sealing methods like cork stoppers, screw caps, or specialized bottle sealing tapes specifically designed for glass bottles.

- Q: Can packaging tape be used for sealing packages for shipping?

- Yes, packaging tape can be used for sealing packages for shipping. Packaging tape is specifically designed to securely seal packages and keep them intact during transit. It provides a strong and durable bond that can withstand the rigors of shipping and handling. Whether you are shipping small or large packages, packaging tape is an essential tool to ensure that your items are properly sealed and protected during transportation.

- Q: Can packaging tape be used for sealing retail or product packaging?

- Yes, packaging tape can be used for sealing retail or product packaging.

- Q: Can packaging tape be used for other purposes besides packaging?

- Yes, packaging tape can definitely be used for other purposes besides packaging. Due to its strong adhesive properties and durability, it can be used for a variety of tasks. For example, it can be used for household repairs such as fixing a broken book spine or securing loose cables. Additionally, it can be used for crafting projects like creating temporary or permanent decorations, making durable envelopes, or even in DIY projects like creating makeshift labels or organizing items. Furthermore, packaging tape can also be used for temporary fixes, such as sealing small leaks or cracks in pipes or containers until a permanent solution is found. The versatility of packaging tape makes it a handy tool to have around the house or office for various purposes beyond just packaging.

- Q: Can packaging tape be used for sealing packages with heavy-duty construction materials?

- Indeed, packaging tape possesses the capability to seal packages that encompass robust construction materials. Its purpose lies in furnishing powerful adhesion and endurance, rendering it fitting for the task of safeguarding packages harboring heavy-duty construction materials. Nevertheless, it is of utmost importance to meticulously select a packaging tape exclusively engineered for heavy-duty applications, such as reinforced or exceptionally potent tape, in order to guarantee proper sealing and secure transportation. Moreover, it is prudent to fortify the packaging through the utilization of supplementary tape or protective wrapping, contingent upon the weight and fragility of the construction materials, for the purpose of ensuring a safe and secure delivery.

- Q: Can packaging tape be used for sealing plastic storage baskets?

- Yes, packaging tape can be used for sealing plastic storage baskets. It provides a secure and durable seal to keep items inside the basket protected and organized.

- Q: What are the tapes for packing tape?

- There are many kinds: packing tape series: transparent adhesive tape, color adhesive tape

Send your message to us

Eco Friendly PVC Electrical Tape Packed with Bags and Carton

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches