Custom Packaging Tape Designs - PVC Electrical Tape with RoHS Approval

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of PVC Electrical Tape With RoHS Approveal

A thin premium grade plasticized PVC film coated with an aggressive rubber based adhesive with good characteristics. It is highly conformable and unaffected by most chemicals and moisture

Application of PVC Electrical Tape With RoHS Approveal

Electric insulation below 600V; Insulating wrapping of electric wires and cables; Marking of electric wires and cables; Can be used indoors and out door

Available Size of PVC Electrical Tape With RoHS Approveal

Paper Core ID: 76mm; 56mm; 38mm; 32mm

Jumbo Roll size: 1250mm x 33m

Cut roll size: 19mm x 10m; 19mm x 20m or as per customer's requirement

Cut rolls: Nine rolls in one plastic bag, placed in cartons, with or without pallet

Packing of PVC Electrical Tape With RoHS Approveal

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

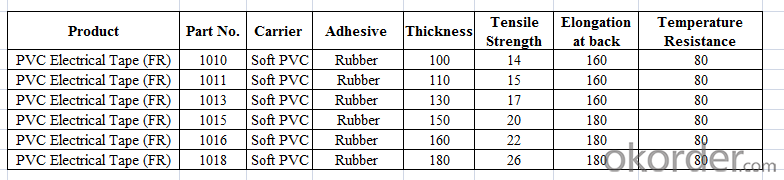

Technical Data of PVC Electrical Tape With RoHS Approveal

Product Show of PVC Electrical Tape With RoHS Approveal

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

- Q: Is packaging tape heat resistant?

- Indeed, packaging tape typically exhibits heat resistance. The composition of most packaging tapes involves materials like polypropylene or acrylic, which possess elevated melting points and can endure extreme temperatures. Thanks to this heat resistance, packaging tape serves diverse purposes, such as sealing boxes and packages that may encounter heat during transportation or storage. Nevertheless, it is crucial to acknowledge that the heat resistance of packaging tape may fluctuate based on the tape's brand and quality. Hence, it is advisable to review the product specifications or seek guidance from the manufacturer to guarantee the tape's appropriateness for the desired utilization and temperature circumstances.

- Q: What are the benefits of using pre-printed packaging tape with warning messages?

- Using pre-printed packaging tape with warning messages offers several benefits. Firstly, it enhances safety by clearly notifying handlers about potential hazards associated with the package. These warning messages can include instructions such as "Fragile," "Handle with Care," or "Do Not Stack," which help prevent mishandling and reduce the risk of damage during shipping or transportation. By providing this important information upfront, pre-printed packaging tape helps to ensure that fragile or sensitive items are handled appropriately, reducing the chances of breakage, leakage, or other accidents. Secondly, it saves time and effort as the warning messages are already printed on the tape. This eliminates the need to separately apply warning labels or write instructions on the package, streamlining the packaging process. It also reduces the chances of errors or inconsistencies in labeling, as the pre-printed tape ensures a standardized and professional appearance. Furthermore, using pre-printed packaging tape with warning messages can enhance the brand image and customer satisfaction. It demonstrates a commitment to quality and safety, which can positively impact customer perception. It also helps to build trust and confidence in the company's products or services, as customers can see that proper precautions are being taken to ensure the safe delivery of their items. Lastly, pre-printed packaging tape with warning messages can also serve as a marketing tool. By including the company logo, contact information, or promotional messages on the tape, businesses can effectively promote their brand and create a lasting impression on customers. This additional visibility can help increase brand recognition and potentially attract new customers. In conclusion, using pre-printed packaging tape with warning messages provides numerous benefits including enhanced safety, time and effort savings, improved brand image, and marketing opportunities. It is a practical and effective solution for businesses looking to ensure the secure and efficient transportation of their products.

- Q: What are the advantages of using packaging tape over other sealing methods?

- Using packaging tape has numerous advantages compared to other sealing methods. Firstly, it provides a robust and secure seal capable of withstanding the challenges of shipping and handling. Its adhesive properties allow it to stick to various surfaces like cardboard, plastic, and metal, ensuring the package remains intact throughout its journey. Secondly, packaging tape is user-friendly and can be applied quickly to seal a package. Unlike glue or staples, it does not require any additional tools or equipment, saving time and enabling efficient packaging processes. Moreover, packaging tape offers versatility in terms of size and strength. It comes in different widths and thicknesses, allowing for customization according to the specific requirements of the package. Whether sealing a small envelope or a large box, there is a packaging tape option that suits your needs. Another advantage of packaging tape is its cost-effectiveness. It is generally more affordable compared to other sealing methods, making it an economical solution for businesses and individuals who frequently ship or package items. Furthermore, packaging tape is tamper-evident, adding an extra layer of security. Once applied, any attempt to tamper with the package will be apparent due to the broken or damaged tape seal. This serves as a deterrent against theft and offers peace of mind to both the sender and recipient. Lastly, packaging tape is easily removable without leaving any residue or damaging the packaging materials. This is particularly useful for packages that may require resealing or for recipients who may want to reuse the packaging. In conclusion, the advantages of using packaging tape include its strength, ease of use, versatility, cost-effectiveness, tamper-evident properties, and ease of removal. These benefits make packaging tape a reliable and efficient choice for sealing packages.

- Q: Can packaging tape be used for sealing packages with delicate fabrics or clothing?

- Yes, packaging tape can be used for sealing packages with delicate fabrics or clothing. However, it is important to exercise caution and take certain precautions to protect the delicate items. Here are a few tips to ensure safe packaging: 1. Use a wide, clear packaging tape: Opt for a wide tape that allows for a larger surface area of adhesion. Clear tape is preferable as it reduces the risk of leaving any visible residue or marks on the fabric. 2. Double-layer the tape: Apply two layers of packaging tape to provide extra strength and security to the package. This will help prevent the tape from accidentally peeling off during transit. 3. Wrap the delicate items securely: Before sealing the package, make sure to wrap the delicate fabrics or clothing in a protective layer, such as tissue paper or bubble wrap. This additional layer will act as a buffer and safeguard the items from any potential damage caused by the tape. 4. Avoid excessive tension: While sealing the package, be careful not to pull too tightly on the tape. Applying excessive tension may cause the fabric to stretch or distort, potentially damaging the delicate item. 5. Consider alternative options: If the delicate item is particularly fragile or valuable, it may be worth considering alternative packaging materials, such as acid-free tissue paper or garment bags. These options provide even more protection and are specifically designed for preserving delicate fabrics and clothing. Ultimately, while packaging tape can be used for sealing packages with delicate fabrics or clothing, it is essential to handle the items with care and take appropriate measures to minimize any potential damage during the packaging process.

- Q: Can packaging tape be used for sealing packages with irregular or uneven surfaces?

- Yes, packaging tape can be used for sealing packages with irregular or uneven surfaces. Packaging tape is designed to adhere to various types of surfaces, including those that may be uneven or irregular. The strong adhesive properties of packaging tape ensure that it securely seals the package, even on surfaces that may not be completely flat or smooth. Additionally, packaging tape is flexible and can conform to the shape of the package, allowing for effective sealing on irregular surfaces. However, it is important to ensure that the tape is applied evenly and pressed firmly onto the surface to maximize its sealing capabilities.

- Q: Can packaging tape be used for sealing chemical or hazardous material containers?

- Sealing chemical or hazardous material containers with packaging tape is not advised due to its lack of necessary properties for effective containment and prevention of leakage. These substances often necessitate specialized containers and sealing methods to ensure safety and compliance with regulations. These specialized containers are engineered to withstand the corrosive or reactive nature of the substances they hold, with seals designed to provide a secure and leak-proof closure. In contrast, using packaging tape can be risky as it may result in leakage, contamination, and exposure to harmful substances. It cannot reliably serve as a barrier against leaks or spills, potentially leading to accidents, injuries, or environmental harm. To properly seal chemical or hazardous material containers, it is recommended to use specific sealing materials that are specifically designed for this purpose. This may involve utilizing specialized caps, gaskets, or seals that are compatible with the specific substance being contained. Moreover, it is crucial to adhere to the guidelines and regulations provided by relevant authorities to ensure the safe handling, storage, and transportation of these materials.

- Q: Is packaging tape resistant to chemicals or solvents?

- Yes, packaging tape is generally resistant to chemicals or solvents. Most packaging tapes are made from materials such as polypropylene or polyvinyl chloride (PVC) which have good chemical resistance properties. These materials are designed to withstand exposure to a wide range of chemicals and solvents commonly encountered in industrial or commercial environments. However, it is important to note that the specific resistance of packaging tape can vary depending on the brand, type, and quality of the tape. Therefore, it is always recommended to check the product specifications or consult the manufacturer for detailed information on the chemical resistance of a specific tape.

- Q: I'd like to know the specifications of the sealing tape. How do you see it? (the following two examples) product name: sealing tape product type: 2.5 inch product specifications: 57mm*80 code (8.5mm thick) weight: about 0.145KG the price for volume: Specifications: code number 48mm*150 meters *40u flesh 20mm here refers to what? I know that 40U means stickiness, so how do I see that?

- Therefore, the seal tape specification is expressed by "width * length * thickness".

- Q: Can packaging tape be used for sealing glass bottles?

- Indeed, glass bottles can be sealed using packaging tape. Nevertheless, it is crucial to acknowledge that packaging tape is not explicitly crafted for the purpose of sealing glass bottles; hence, it may not offer the equivalent level of robustness and air-tightness as dedicated bottle sealing techniques. Moreover, the adhesive on packaging tape may fail to adhere effectively to glass surfaces, potentially resulting in leakage or breakage. To guarantee optimal outcomes, it is advisable to employ appropriate bottle sealing methods like cork stoppers, screw caps, or specialized bottle sealing tapes specifically designed for glass bottles.

- Q: Is the insulating tape waterproof?

- The place is different.There is also a kind of high pressure adhesive tape used in high pressure places.

Send your message to us

Custom Packaging Tape Designs - PVC Electrical Tape with RoHS Approval

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches