Engineering Construction High Preformance Concrete Placing Boom

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

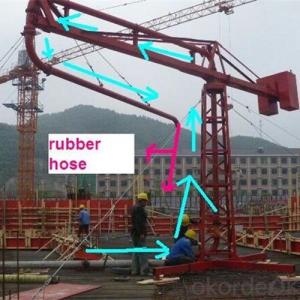

Engineering Construction High Preformance Concrete Placing Boom

PARAMETERS

Manual concrete placing boom parameters

| |||

Specifications | 12meters manual | 15meters manual | 18meters manual |

The big arm design | Dual channel | Dual channel | Dual channel |

Radius of gyration (m) | 12 | 15 | 18 |

The height of the placing boom | 5 | 5 | 5 |

Diameter of conveying pipe (mm) | 125 | 125 | 125 |

Leg span (m) | 3.2*3.2 | 4*4 | 4*4 |

Rotation Methods | Manual | Manual | Manual |

The whole weight (kg) | 1100 | 1200 | 1300 |

With weight (kg) | 600 | 800 | 1000 |

Slewing bearing type | 315 | 315 | 380 |

Material | Channel angle | Channel angle | Channel angle |

Slewing range | 360° | 360° | 360° |

CHARACTERISTICS

1. Frame arm structure, increasing the loadingcapacity and stability.

2. Highquality rotary bearing, flexible rotation

3. Doublesupporting leg, improve the stability and bearing capacity of double

4. Withexcellent steel GB, the Firmness is Enhanced several times compared to Angleiron

5. Minimal impact on the appearance of vibrationforce

6. Withfour rope, ensure that the safety of product using.

PIPE SPECIFICATIONS

| 12M Concrete Placing Boom | ||

Name | Specifications | Quantity |

| Straight Pipe | 3.67M | 1 |

| 4.24M | 1 |

| 5.6M | 1 |

| Delivery Bend | 148-148 R275 90° | 2 |

| 157-148 R275 90° | 1 |

| R500 * 90° | 1 |

| 15M Concrete Placing Boom | ||

| Name | Specifications | Quantity |

| Straight Pipe | 3.67M | 1 |

| 5.56M | 1 |

| 5.8M | 1 |

Delivery Bend | 275*90 add pipe | 1 |

| 148-148 R275 90° | 1 |

| 157-148 R275 90° | 1 |

| R500 * 90° | 1 |

| 18M Concrete Placing Boom | ||

| Name | Specifications | Quantity |

| Straight Pipe | 3.7M | 2 |

| 3M | 1 |

| 7M | 1 |

| Delivery Bend | R500 90° | 1 |

| R275 90° | 1 |

| R275 90° +130 | 1 |

| 157-148 R275 900 | 1 |

Delivery& packing & payment

1. FOB Tianjin or others.

2. Delivery time: within 15 days.

3. Packing: Export standard packing , Seaworthy packing,or according to the customer demand

4. Payment term: T/T, L/C.

5. MOQ: 1 set or according the actual situation.

- Q: What are the specifications of concrete spreader?

- Rotary: rotary, rotary and double rotary bearings; is a kind of new construction machinery and supporting the use of concrete conveying pump tube

- Q: What is the difference between concrete pump truck and concrete distributor in construction?

- Automobile pump flexible tubing can flexibly rotate 360 degrees, the body shift is also very convenient, the pumping efficiency is relatively high, but the cost is more expensive.

- Q: How to install and use the distributor?

- In order to prevent the cable leakage wounding, should be used in three-phase five wire system, the "three distribution", "two levels of protection", to implement a machine a gate of an insurance, lighting line equipment switch installation, the nearest place, in case of emergency hand brake pull

- Q: What are the acceptance items of concrete spreader?

- The transmission mechanism of the protective cover, etc., each part is firmly connected cloth machine should maintain a certain distance with high voltage and electrical lines, the end of the pouring hose must fasten safety flies, prohibit the use of the length of more than 3 meters water column end hose, hose into the column shall be poured concrete, in strict accordance with the scope of work cloth machine. Work fabric machine under arms are not allowed to stand

- Q: How to fit the cloth rod of the distributor?

- Place the distributing rod and its counterweight, and request that the center of the cloth pole must be 200~300mm overhead. The sleepers or wooden side will be set under the feet to see whether the cloth pole body is straight

- Q: What are the weekly inspection items for concrete spreader?

- Check the wear of the pipe, the arm thickness is less than 2mm, should be replaced in a timely manner

- Q: What is the working principle of the distributor?

- The distributing machine is arranged at the center of each casting position, and meets the requirement of pouring position through the bent pipe and the hose

- Q: How to maintain the concrete spreader?

- Four screw high precision quantitative cloth is adopted, and the error of cloth quantity is less than 2%. According to the field process, the traveling speed and the cloth speed are stepless flexible adjusted

- Q: How to distinguish tower type distributor and general distributor?

- Avoid large arm distortion caused by huge pressure and vibration of concrete pump during construction

- Q: What is the structure of a concrete distributor?

- Structure: bolt, and the vertical frame, which is fixed on the base part, through the slewing bearing and the top rotating part is connected on the main beam, and the balance arm, the balance arm rod, such that after the formation of the upper transverse rotating part

Send your message to us

Engineering Construction High Preformance Concrete Placing Boom

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords