Electric Ball Valve Side Entry Design, Top Entry Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

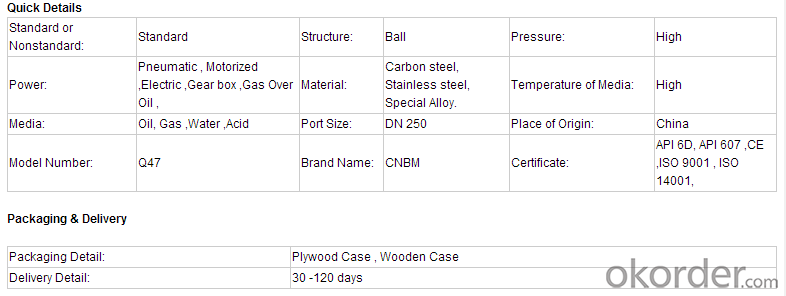

Specifications

Side Entry Design, Top Entry Design.

Bolted Body Or Fully Welded Body.

Full Bore Or Reduced Bore.

Size: 2"- 40", DN 50-1000mm

Pressure: 150 -1500LB, PN 10-40

Material: Carbon steel, Stainless Steel, Special Alloy.

Electric Ball Valve

Design Feature:

Side Entry Design, Top Entry Design.

Bolted Body Or Fully Welded Body.

Full Bore Or Reduced Bore.

Flanged End Or Welding End.

Double Block and Bleed.

Locking Device.

Single Piston Effect, Double Piston Effect.

Automatic Internal Relief of Body Pressure.

Emergency Sealant Injection System.

Fire Safe Design. Antistatic Device.

Anti-Blowout Stem Design.

Body Vent Device.

Stem Extension for Underground Service.

Product Range:

Size: NPS 2”~ 40” , DN 50-1000

Pressure Rating: Class 150 -1500 LB , PN 10~40

Design standard : API 6D , EN13942

Face To Face Dimension : API 6D , EN 558-1, EN 12982

Connecting Dimensions: ASME B16.5, ASME B16.47, ASME B 16.25, EN 1092-1, and EN 12627.

End Connection: Flange, BW.

Body Materials: Carbon steel, Stainless Steel, Special Alloy.

Medium: Natural Gas, Oil, Steam

- Q: Electric ball valve installation need to pay attention to what?

- 8, electric and pneumatic valve in order that no special contract allows only vertically installed in the indoor use. 9, after the completion of the pipeline construction, all the valves on the pipeline line shall be opened and the residual dirt shall be removed.

- Q: What is the maximum temperature resistance of the 304 stainless steel ball valve?

- What seal do you have?.PTFE sealing maximum temperature: 120 degreesMetal seal maximum temperature: 325-400 degrees, look at the manufacturers.

- Q: What does "ball pq340h-10c-1200" mean?

- This is the worm gear eccentric hard seal hemisphere valve, 10 kilograms of pressure, caliber is 1200.

- Q: Please professional help guide: accidental discovery of connection pipe and valve (mark position diagram) can rotate, but there is no problem with the 10 Water Leakage.Please professional help guide: accidental discovery of connection pipe and valve (mark position diagram) can rotate, but there is no Water Leakage problem, while the valve under the same position is fixed and can not rotate, will this situation is normal? Is it possible to leak water in the future?

- Abnormal, should be fixed, a long time may leak.

- Q: The two valves are available for the flow of the electromagnetic valve switch, I contact more, found for water solenoid valve are caged water, to repair several times because of impurities or newly installed pipeline with raw materials flowing through the valve, close the valve body when not to rely on Yan, a seepage water tank to diffuse phenomenon!I am looking for a replacement, I think the electric valve should be a good choice, not used to a conclusion.Please use the electric ball valve to talk about friends, or for the two kinds of friends who have an understanding to talk aboutOr there is no better substituteThere seems to control the solenoid valve and electric valve is not the same, the solenoid valve is normally open and closed to control the electric valve is controlled by the trigger (like), if used to replace it, what is the controller?

- I think you should use the solenoid valve is diaphragm type, and not particularly good products, diaphragm solenoid valve in the closed position when the diaphragm is easy to change, resulting in pipe die, or medium impurities caused the pilot hole is blocked, the valve will not move, so the diaphragm solenoid valve. Is there a film guide card member, so that each position of the diaphragm in the correct position, but the pilot hole is not a solution, of course, you can use direct action solenoid valve, such problems are solved. The electric ball valve than the pilot solenoid valve in this respect, but the cost of this fear is much higher, especially the pipe diameter is not so, it does not pay!

- Q: What's English for ball valves?

- Mechanical introductionThe main characteristics of the electric ball valve of the valve itself is compact, easy operation and maintenance for water, solvents, acids, and natural gas general working media, but also applies to poor working conditions of media, such as oxygen, hydrogen peroxide, methane and ethylene. Ball valve body can be integrated, or can be combination. Ball valve in the pipeline is mainly used to do cutting, distribution and change the direction of flow medium. Ball valve is a new type of valve widely adopted in recent years. The resistance of fluid is small, and its resistance coefficient is equal to that of pipe of same length.The ball valve is simple in structure, small in size and light in weight. Tight and reliable, at present, the ball valve sealing surface materials widely used in plastic, good sealing, vacuum systems have been widely used. Convenient operation, open and close rapidly, from fully open to fully closed as long as 90 degree rotation, facilitate remote control. Easy maintenance, ball valve structure is simple, the sealing ring is generally movable, disassembly and replacement are more convenient. In full open or full closed, the ball and valve seat sealing surface and dielectric isolation, the media through, will not cause the valve sealing surface erosion. Wide range of applications, from a few millimeters to a few millimeters, large to a few meters, from high vacuum, high pressure can be applied.It is generally believed that the ball valve is suitable for direct opening and closing, but the development of the ball valve has been designed to make it throttling and controlling the flow. The main features of the valve itself is compact, easy operation and maintenance for water, solvents, acids, and natural gas general working media, but also applies to poor working conditions of media, such as oxygen, hydrogen peroxide, methane and ethylene. Ball valve body can be integrated, or can be combination.

- Q: Is the drain valve the same as the ball valve?

- Not the same, the drain valve generally refers to the pressure relief valve, when the pipe pressure exceeds the pressure set by the valve, it began to relieve pressure, when the pipe is less than the pressure set by the valve, automatically shut down. Ball valve can only achieve the switch function. Of course, if you take the ball valve as the drain valve, you can also only manually manual operation, and the pressure relief valve is automatic.

- Q: What are the CF8 and CF3M marks on the stainless steel ball valves?

- Hello, CF8 stands for 304 material, and CF3M stands for 316L material. It's stainless steel

- Q: Daily maintenance and common maintenance of ball valves, Q347F-16C and Q41F-16C

- Structural type code:Floating type: 1 means through flow, 2 indicates Y type three pass, 4 represents L type three pass, and 5 represents T type three pass;Fixed type: 0 represents the straight through of the hemisphere, the 6 represents the four channel, the 7 indicates the through flow, the 8 represents the L type three pass, and the 9 represents the Y type three pass;Sealing material: B Babbitt, fluorine rubber, F F46, H direct machining of fluorine lining, rubber lining, stainless steel J M Monel alloy, N nylon plastics, Monel P, Y alloy, W valve;Pressure rating code: 16 said the pressure of 16 kg (1.6Mpa) up to 64Mpa; 150LB said American Standard pound pressure, maximum pressure rating up to 2500LB (150LB=1.6MPA/300LB=2.5-4.0mpa/400LB=6.4mpa/600LB=10mpa); 5K said on stage pressure, the maximum pressure of 63K;Body material: A titanium and titanium alloy, C steel, I stainless steel, chrome molybdenum steel, P18-8 stainless steel, S plastic, RMo2Ti.

- Q: The difference between ball valve q41f46-16c and q41f46-16

- There is no difference. If the latter model is P, then the stainless steel flange lining fluorine ball valve, the former is cast steel material.Q41F46-16C is the type of ball valve, cast steel flange lining fluorine ball valve!

Send your message to us

Electric Ball Valve Side Entry Design, Top Entry Design

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords