Easy Open Strong Resealable Bag Sealing Tape for PE Bag

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days For 1 x 20FCL roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

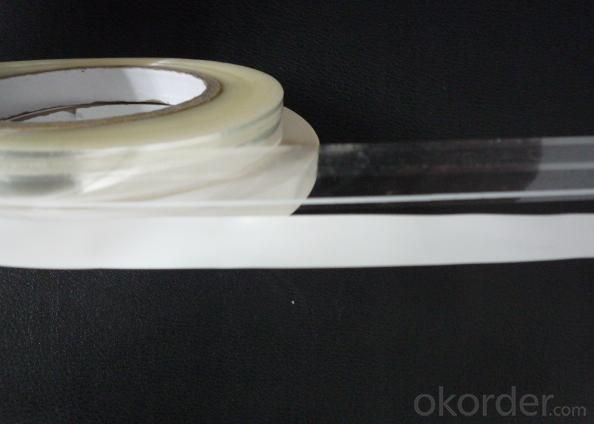

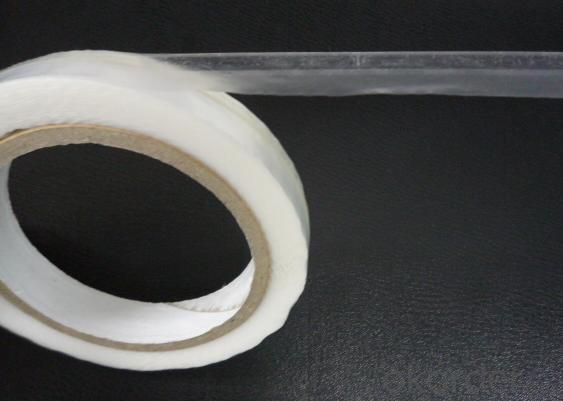

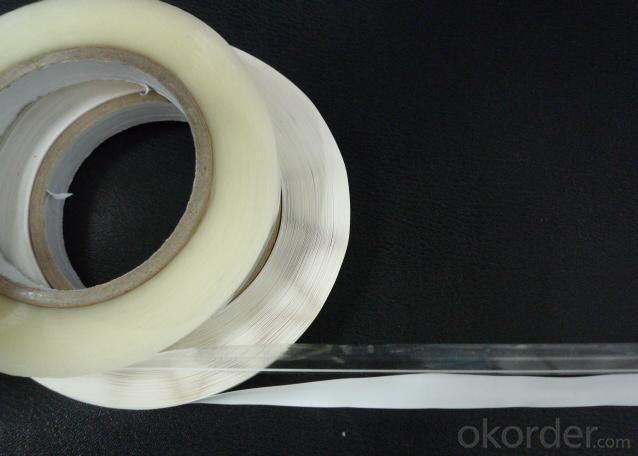

Specifications Of strong resealable bag sealing tape for PE bag:

Suitable for sealing plastic bags such as OPP or PP .PE materials.

Reusable, no peel off of adhesive, no residue.

It does not react chemically with the contents of the bags to color changes etc.

Name Bag Sealing Tape

Item No BG-14

Carrier PET film

Release Liner PE Film

Adhesive Acrylic Adhesive

Release Liner width 13/14mm

Carrier Width 6mm

AB Side Coating Width 4mm/7mm (middle glue)

Service Of strong resealable bag sealing tape for PE bag:

We have a group of professional technicians and workers with rich experience, who are dedicated in this industry and try to offer best service to every customer. We are undertaking the idea of “reliable quality, reasonable price, and good service” to meet the needs of every customer. Your success is our goal, and your content is our hope. We keep pursuing “exact production, high-quality service”.

Handing and Storage Of strong resealable bag sealing tape for PE bag:

Handling procedures:Caution with edge of sheet. After using this sheet, wash hands.

Storage procedures:Keep dry and cool and away from direct sunlight for quality.

Stability and Reactivity Of strong resealable bag sealing tape for PE bag:

Chemical Stability: Stable and non-reactivity

Conditions to Avoid: Away from high temperature

Incompatibility with various substances:specific materials/condition to avoid.

Hazardous Decomposition Products:Thermal decomposition will produce mainly C02,and slightly CO.

Hazardous Polymerization:Can not occur

- Q: Can packaging tape be used for sealing packages with electronic components?

- Yes, packaging tape can be used for sealing packages with electronic components. However, it is important to ensure that the tape used is anti-static or ESD (electrostatic discharge) safe, as regular packaging tape can generate static electricity and potentially damage the sensitive electronic components.

- Q: What are the advantages of using packaging tape over other sealing methods?

- Using packaging tape has numerous advantages compared to other sealing methods. Firstly, it provides a robust and secure seal capable of withstanding the challenges of shipping and handling. Its adhesive properties allow it to stick to various surfaces like cardboard, plastic, and metal, ensuring the package remains intact throughout its journey. Secondly, packaging tape is user-friendly and can be applied quickly to seal a package. Unlike glue or staples, it does not require any additional tools or equipment, saving time and enabling efficient packaging processes. Moreover, packaging tape offers versatility in terms of size and strength. It comes in different widths and thicknesses, allowing for customization according to the specific requirements of the package. Whether sealing a small envelope or a large box, there is a packaging tape option that suits your needs. Another advantage of packaging tape is its cost-effectiveness. It is generally more affordable compared to other sealing methods, making it an economical solution for businesses and individuals who frequently ship or package items. Furthermore, packaging tape is tamper-evident, adding an extra layer of security. Once applied, any attempt to tamper with the package will be apparent due to the broken or damaged tape seal. This serves as a deterrent against theft and offers peace of mind to both the sender and recipient. Lastly, packaging tape is easily removable without leaving any residue or damaging the packaging materials. This is particularly useful for packages that may require resealing or for recipients who may want to reuse the packaging. In conclusion, the advantages of using packaging tape include its strength, ease of use, versatility, cost-effectiveness, tamper-evident properties, and ease of removal. These benefits make packaging tape a reliable and efficient choice for sealing packages.

- Q: How do you choose the right packaging tape for your needs?

- When it comes to selecting the appropriate packaging tape for your requirements, there are various factors to take into consideration. To begin with, ponder over the nature of the items you will be packaging. If you are dispatching weighty or bulky items, you will need a tape that is sturdy and long-lasting, such as a heavy-duty or reinforced tape. Conversely, if you are packaging lightweight items, a standard packaging tape may suffice. Moving forward, contemplate the surroundings in which the package will be stored or transported. If the package will be exposed to extreme temperatures or moisture, it is advisable to opt for a tape that is resistant to these conditions, such as a weather-resistant or waterproof tape. This will ensure that your package remains intact and safeguarded throughout its journey. Furthermore, take into account the surface onto which the tape will be affixed. If you are packaging boxes with smooth surfaces, a standard adhesive tape will suffice. However, if you are packaging boxes with rough or textured surfaces, you may require a tape with a stronger adhesive, such as an acrylic or hot melt tape, to ensure proper adhesion. Additionally, consider the length and width of the tape roll. If you will be packaging a large number of items, it may be preferable to select a tape roll with a longer length to minimize the need for frequent replacements. Similarly, if you are packaging larger boxes, a wider tape roll may provide better coverage and security. Lastly, take your budget into account. Packaging tapes are available in a range of prices, so it is crucial to strike a balance between your needs and your budget. While it may be tempting to opt for cheaper options, bear in mind that investing in a higher-quality tape can save you time, effort, and potential damages in the long run. By considering the type of items, environmental conditions, surface texture, roll length and width, and your budget, you can choose the appropriate packaging tape that caters to your specific needs and offers the necessary strength, durability, and security for your packages.

- Q: Can packaging tape be used for sealing poly mailers?

- Indeed, poly mailers can be sealed using packaging tape. Typically, packaging tape is employed to secure diverse packaging materials, including poly mailers. This tape offers a robust and reliable seal, safeguarding the contents from spilling out or experiencing interference while in transit. Nevertheless, it is crucial to apply the tape correctly and firmly to maintain the seal's integrity. Moreover, it is advisable to opt for a top-notch packaging tape specifically designed for secure sealing to achieve optimal outcomes.

- Q: Is packaging tape safe to use on painted furniture?

- Yes, packaging tape is generally safe to use on painted furniture. It is designed to adhere to various surfaces, including painted surfaces, without causing damage or leaving residue when properly applied and removed. However, it is always recommended to test a small, inconspicuous area first to ensure compatibility and to handle the tape with care to avoid any potential paint or finish peeling.

- Q: How long does packaging tape last?

- The longevity of packaging tape largely depends on various factors such as the quality of the tape itself, the conditions it is exposed to, and how it is stored. Generally, packaging tape can last for several months to a few years. However, it is important to note that over time, the adhesive properties of the tape may begin to weaken, causing it to lose its sticking power. Exposure to extreme temperatures, moisture, and sunlight can also accelerate the deterioration of the tape. Therefore, it is advisable to use packaging tape within its recommended shelf life and store it in a cool and dry place to ensure its effectiveness when needed.

- Q: How do I choose the right packaging tape for my needs?

- To guarantee your packages are securely sealed during transit, it is crucial to make a careful decision when selecting the appropriate packaging tape. Here are some factors to take into account: 1. Strength and durability: Take into consideration the weight and nature of your packages. For heavy or bulky items, it is advisable to choose a tape with high tensile strength that can withstand rough handling. Look for tapes made from materials like fiberglass or reinforced with polyester fibers. 2. Adhesive type: Various packaging tapes use different types of adhesives. Acrylic adhesive is commonly used and provides a good balance of performance and affordability. For challenging surfaces or extreme conditions, consider using hot melt adhesive, which offers superior bonding strength. Furthermore, water-activated tape, also known as gummed paper tape, forms a permanent bond when moistened, providing enhanced security. 3. Width and length: Determine the appropriate width and length of tape based on the size of your packages. Thicker tapes are generally more durable, and longer rolls may be more cost-effective for high-volume packaging. 4. Transparency and aesthetics: If you desire a professional appearance for your packages or need to easily see the contents, opt for clear or transparent packaging tape. However, if appearance is not a concern, colored tape can aid in easy identification or branding purposes. 5. Environmental considerations: If you are environmentally conscious, look for packaging tapes made from eco-friendly materials or those that are recyclable. Some tapes are water-based, solvent-free, or made from renewable resources, making them a greener choice. 6. Dispenser compatibility: Take into account the type of tape dispenser you have or plan to use. Ensure that the tape you choose is compatible with your dispenser, as certain tapes necessitate specific types of dispensers. 7. Cost: Finally, compare prices and consider your budget. However, bear in mind that sacrificing quality for a lower price may result in inadequate tape performance and potential damage to your packages. By considering these factors, you can make an informed decision and select the appropriate packaging tape that best suits your needs, ensuring your packages arrive securely and intact.

- Q: Can packaging tape be used for sealing sports equipment or gear?

- Yes, packaging tape can be used for sealing sports equipment or gear. It provides a strong and secure seal, helping to protect the equipment during transportation or storage. However, it's important to ensure that the tape is applied properly and that it doesn't damage or hinder the functionality of the gear.

- Q: What's the tape for sealing tape?

- The base material of the sealing adhesive tape is BOPP film.BOPP is a very important flexible packaging material, and has been widely used. BOPP film is colorless, odorless, tasteless, non-toxic, and has high tensile strength, impact strength, rigidity, toughness and good transparency. It is a high quality substrate for making transparent sealing tape. BOPP film has low surface energy, and it needs corona treatment before gluing or printing. However, the BOPP film has good printing adaptability after corona treatment. It can be printed by printing and has a beautiful appearance, so it is often used as the surface material of composite films. BOPP film is also inadequate, such as easy accumulation of static electricity, no heat sealing and so on. In the high-speed production line, BOPP film is easy to generate static electricity. Electrostatic eliminator is necessary. In order to obtain the BOPP heat seal film, can be on the surface of BOPP film after corona treatment coating heat sealing resin glue, such as PVDC, EVA latex latex, can also be coated with solvent glue, coating or extrusion method can be applied to the production of extruded composite heat sealing film BOPP. The film is widely used in bread, clothing, footwear and other packaging, and cigarettes, books cover packaging. The tear strength of BOPP film increases after stretching, but the secondary tearing strength is very low. Therefore, no cut can be left at the ends of the BOPP film, otherwise the BOPP film is easy to tear when printed and compounded. BOPP coated self-adhesive, we can produce our commonly used sealing tape, tape sealing tape, is a larger amount of BOPP market.

- Q: What type of rubber tape and hot-melt tape?

- Application of duct tape 2, duct tape is mainly used for carton sealed, carpet seams together, heavy packing, waterproof packaging etc.. At present in the automotive industry, paper industry, mechanical and electrical industry also frequently used, for automobile cab, chassis, cabinets and other waterproof measures better place. Easy die cutting.3, tape tape according to different classification can be divided into hot melt glue, tape, rubber tape.

1. Manufacturer Overview

| Location | Zhengzhou, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 2 Million |

| Main Markets | 20.00% Southeast Asia 20.00% South America 10.00% Eastern Europe 10.00% North America 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 19% - 22% |

| No.of Employees in Trade Department | 20-50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Easy Open Strong Resealable Bag Sealing Tape for PE Bag

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- 30 Days For 1 x 20FCL roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords