Packaging Tape Walmart - Stationery Glue, BOPP Adhesive Tape, Masking Tape Tapes

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CONSTRUCTION:

Carrier: BOPP film

Adhesive: Water based acrylic adhesive.

TYPICAL PHYSICAL PROPERTIES:

Total Thickness (adhesives + carrier): 42 ± 1 um

Adhesive thickness:20 ± 1 um

Initial Tack: ³ 23#

180O Peel Adhesion (to steel): ³ 6.52 N /25mm

Holding Power: ³ 31 hrs

PACKING:

Core I.D.: 3” (76mm±1)

Jumbo Roll:1280mm x 4000m

Cut Roll: As per customer’s requirements

Application:

Carton sealing & packing, Light duty packaging, bundling, holding, and other office & household use.

REMARKS:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and be kept away wet and/or heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

Advantage to recommend:

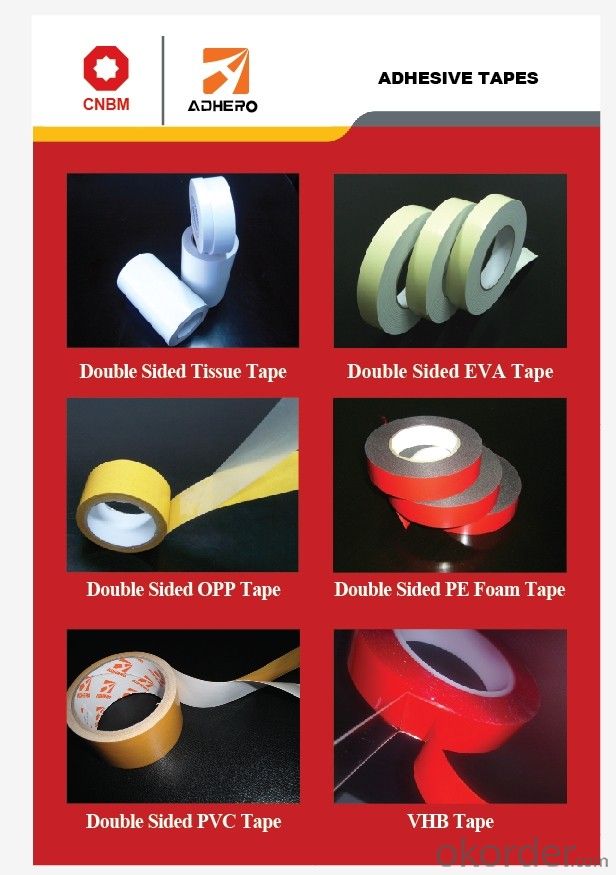

We supply a wide range of products, which include double sided adhesive tape, masking tape, kraft tape, cloth tape, BOPP tape and so on.

Our biggest item is double side tape. Our double-sided adhesive tapes are with the carriers of tissue, PET, OPP, cloth, PE foam and EVA foam. And the adhesives involved are water based, solvent based and hot-melt acrylic adhesive.

According to different temperature resistances, we have two categories of masking tapes separately for general purpose and high temperature from 100°C to 160°C.

We also produce kraft tape, cloth tape and BOPP tape.

We have as our principle “Clients’ need comes first”. So we have a good variety of technical properties and sizes to meet with your different needs.

Our products enjoy popularity in markets because they have super quality with competitive price and good service.

Adhero is your ideal choice for excellent adhesive tapes and solutions.

TAPE FAQ:

What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

Can Adhero accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

What are the international commodity codes for these products?

HS Code: 48231900.

Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

What are the temperatures resistances of your masking tape?

we have two general kinds of masking tapes separately for general purpose 60°C and high temperature 100°C to 160°C.

Are you a manufacturer or just a trader?

We are a professional manufacturer.

How about the quality?

The quality is very good. We have large and advanced product line.welcome to visit our company.

- Q: What are the benefits of using UV-resistant packaging tape?

- UV-resistant packaging tape offers numerous advantages. Firstly, it is specifically designed to endure prolonged exposure to sunlight, preventing it from deteriorating or degrading. This is particularly crucial when shipping or storing items outdoors or in areas with direct sunlight. With UV-resistant tape, packages can remain securely sealed for extended periods as it maintains its adhesive properties and structural integrity. Furthermore, UV-resistant packaging tape safeguards the contents of packages from UV ray damage. Sunlight can cause materials like paper, fabrics, or plastics to fade, discolor, or degrade. By utilizing UV-resistant tape, these items are shielded from the harmful effects of UV rays, preserving their quality and appearance. Moreover, UV-resistant packaging tape boasts long-lasting adhesion. Unlike regular tape, which may lose its stickiness over time when exposed to sunlight, UV-resistant tape is specially formulated to bond tightly and securely to various surfaces. This reliable adhesion minimizes the risk of packages opening or items sustaining damage during transit. Additionally, UV-resistant packaging tape provides peace of mind for both senders and recipients. By opting for tape that is resistant to UV rays, businesses and individuals can ensure that their packages arrive in the same condition they were sent, enhancing their professional image and customer satisfaction. This advantage is particularly vital when shipping valuable or delicate items that require extra protection. In conclusion, UV-resistant packaging tape offers enhanced durability, protection against UV damage, long-lasting adhesion, and increased confidence in package integrity. By selecting UV-resistant tape, individuals and businesses can effectively safeguard their packages and their contents, even when exposed to prolonged sunlight.

- Q: Can packaging tape be used for sealing metal boxes?

- Yes, packaging tape can be used for sealing metal boxes. It provides a strong adhesive bond and helps secure the contents inside the metal box.

- Q: Can packaging tape be used on different materials?

- Indeed, various materials can be affixed with packaging tape. Packaging tape exhibits versatility as it can adhere to a broad spectrum of surfaces, encompassing cardboard, plastic, metal, glass, and even fabric. Its primary purpose is to yield a robust and steadfast seal, guaranteeing the preservation of packages throughout their journey and storage. Whether one aims to seal a cardboard box, consolidate multiple items, or fasten a package, packaging tape proves to be an efficacious option for an array of materials.

- Q: What are the alternatives to packaging tape?

- Some alternatives to packaging tape include adhesive-free packaging solutions like interlocking flaps, self-sealing envelopes, or Velcro straps. Additionally, eco-friendly options like paper-based or biodegradable tapes can be used.

- Q: Does packaging tape come in different colors?

- Yes, packaging tape is available in different colors.

- Q: Can packaging tape be used for securing pallet loads?

- Yes, packaging tape can be used for securing pallet loads. Packaging tape is commonly used to secure boxes and packages, but it can also be used to reinforce and secure pallet loads. It helps to hold the items on the pallet together, preventing them from shifting or falling off during transportation or storage. However, it's important to note that the effectiveness of packaging tape for securing pallet loads may depend on the weight and stability of the items being transported. In some cases, additional strapping or banding may be needed for extra security.

- Q: Can packaging tape be used for sealing electronics or appliances?

- Packaging tape is not recommended for sealing electronics or appliances. While packaging tape is designed to securely seal cardboard boxes and packages, it is not suitable for sealing electronics or appliances due to various reasons. Firstly, packaging tape does not provide adequate protection against moisture or dust, which can be harmful to electronic components. Electronics and appliances require airtight sealing to prevent any damage or corrosion caused by moisture or dust particles. Secondly, packaging tape is not designed to withstand high temperatures or extreme conditions that electronics or appliances may be subject to during storage or transportation. The adhesive used in packaging tape may not be able to withstand heat or cold, which could lead to the tape peeling off and leaving the item unprotected. Thirdly, electronics and appliances often have delicate surfaces that can be easily scratched or damaged by the adhesive on packaging tape. The sticky residue left behind by the tape can also be difficult to remove from sensitive surfaces. Therefore, it is advisable to use appropriate sealing methods and materials specifically designed for electronics or appliances. These may include specialized tapes, foam gaskets, or custom-fitted protective covers. It is always recommended to consult the manufacturer's guidelines or seek professional advice when sealing electronics or appliances to ensure proper protection and functionality.

- Q: How do I prevent packaging tape from becoming too loose?

- To prevent packaging tape from becoming too loose, here are a few tips: 1. Use quality packaging tape: Invest in good quality packaging tape that has a strong adhesive. Low-quality tapes tend to lose their stickiness quickly, leading to loose packaging. 2. Clean and dry surfaces: Before applying the tape, ensure that the surfaces are clean and dry. Dust, moisture, or oil can weaken the adhesive, causing the tape to become loose. 3. Apply firm pressure: When sealing a package, apply firm pressure while pressing the tape onto the surface. Make sure to run your hand or a flat object along the length of the tape to ensure proper adhesion. 4. Overlap the tape: Instead of just placing a single strip of tape, overlap it by a few inches. This overlap provides extra strength and reduces the chances of the tape becoming loose. 5. Avoid extreme temperature changes: Extreme temperature changes can affect the adhesive properties of packaging tape. Avoid storing packages in areas with high humidity or extreme temperature variations, as this can cause the tape to loosen. 6. Reinforce with additional tape: If you are sealing a heavy or bulky package, consider reinforcing it with additional tape. Apply extra strips of tape across the sides or diagonally to provide extra support and reduce the risk of the tape coming loose. 7. Store packages properly: When storing packages, ensure they are stacked properly and not subjected to excessive pressure or weight. Poor storage conditions can cause the tape to loosen over time. By following these tips, you can prevent packaging tape from becoming too loose, ensuring that your packages remain securely sealed during transit or storage.

- Q: Can packaging tape be used for securing pallet loads?

- Indeed, pallet loads can be secured using packaging tape. Although packaging tape is typically utilized for securing boxes and packages, it is also applicable for fortifying and securing pallet loads. It efficiently keeps the items on the pallet intact, averting any potential movements or accidents during transportation or storage. Nevertheless, it is essential to acknowledge that the efficacy of packaging tape in securing pallet loads might rely on the weight and stability of the transported items. There may be instances wherein additional strapping or banding is necessary to provide supplementary security.

- Q: Can packaging tape be used for sealing food containers?

- Using packaging tape to seal food containers is not recommended. Although it may effectively secure boxes and packages, it is not suitable for use with food. It is important to seal food containers with materials specifically designed for food contact, such as food-grade plastic wrap, aluminum foil, or airtight reusable food storage containers. Applying packaging tape to food containers can introduce hazardous chemicals or adhesives that may contaminate the food, compromise its quality, or pose health risks. Therefore, it is crucial to prioritize food safety by using approved materials exclusively for sealing food containers.

Send your message to us

Packaging Tape Walmart - Stationery Glue, BOPP Adhesive Tape, Masking Tape Tapes

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches