Custom Packaging Tape Green Masking Tape 160 Micron SGS & ISO9001 Certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Masking Tape is of crepe paper as the carrier, coating with rubber adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Masking Tape: widely used for paint masking, furniture, shoe material production, automobile painting, light duty packaging etc.

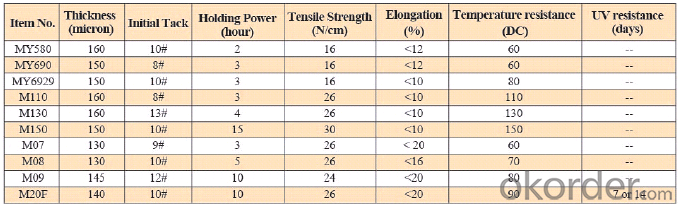

Typical Physical Reports of PVC Electrical Tape

Packaging

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Length 1800mm; width according to customers’ requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Masking Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: How do I prevent packaging tape from wrinkling?

- Here are some steps you can take to prevent packaging tape from wrinkling: 1. Utilize a tape dispenser: Using a tape dispenser aids in achieving a smooth application of the tape, reducing the likelihood of wrinkling. It also grants better control during taping, making it easier to keep the tape straight and taut. 2. Apply the tape tightly: When applying the tape, pull it firmly as you adhere it. This prevents any slack or loose areas that may cause wrinkling. Be cautious not to stretch the tape excessively, as this could diminish its adhesive properties. 3. Opt for the appropriate tape type: Different types of packaging tape possess varying adhesive properties and thicknesses. Selecting a high-quality tape specifically designed for packaging can minimize wrinkling. Additionally, consider using tape with reinforced fibers for added strength and resistance to wrinkling. 4. Ensure a clean surface: Before applying the tape, ensure that the surface is free from dust, dirt, or any other debris. These particles can cause the tape to wrinkle or adhere improperly. Thoroughly clean the surface and allow it to dry before taping. 5. Avoid extreme temperatures: Packaging tape can be sensitive to temperature changes, which may lead to wrinkling. Refrain from using the tape in extremely cold or hot environments. If possible, store the tape in an area with controlled temperature before usage. 6. Apply pressure: After applying the tape, use your hand or a roller to exert pressure on it, ensuring proper adhesion. This helps smooth out any potential wrinkles or bubbles and ensures a secure attachment of the tape. By following these suggestions, you can significantly diminish the likelihood of packaging tape wrinkling, resulting in a more orderly and secure package.

- Q: Is packaging tape easy to write on?

- Yes, packaging tape is generally easy to write on. It provides a smooth surface for writing and most pens or markers adhere well to it, allowing you to write clearly and legibly on the tape.

- Q: Can packaging tape be used for sealing arts and crafts materials?

- Packaging tape is indeed suitable for sealing arts and crafts materials. Its versatility as an adhesive enables it to effortlessly attach and secure a wide range of materials such as paper, cardboard, fabric, and more. Whether you need to seal envelopes, wrap gifts, or engage in art projects, packaging tape guarantees a sturdy and durable bond, ensuring the secure sealing of your arts and crafts materials. Moreover, its transparent nature allows it to seamlessly blend with your project, making it an exceptional option for sealing arts and crafts materials.

- Q: Can packaging tape be used for sealing plastic containers?

- Yes, packaging tape can be used for sealing plastic containers. Packaging tape is designed to adhere to various surfaces, including plastic, and provides a secure seal to prevent the contents of the container from spilling or getting damaged. It is commonly used for sealing boxes during shipping or storage, but it can also be used effectively on plastic containers. However, it is important to ensure that the tape is firmly applied and that all edges and seams are properly sealed to maintain the integrity of the container.

- Q: Is packaging tape flammable?

- Yes, packaging tape is typically made from materials such as polypropylene or polyester, which are not highly flammable. However, it is important to note that some packaging tapes may have adhesive properties that contain flammable components. It is always best to refer to the specific packaging tape's safety data sheet or consult the manufacturer for accurate information regarding flammability.

- Q: What are the considerations for using packaging tape on textured surfaces?

- There are several factors to consider when using packaging tape on textured surfaces. To begin with, the texture of the surface can impact how well the tape sticks. Textured surfaces often have uneven or rough areas that can make it challenging for the tape to securely adhere. It is crucial to select packaging tape that is specifically designed for textured surfaces. These tapes have a stronger adhesive that can better stick to uneven surfaces, ensuring that the tape remains in place. Another factor to think about is the tape's durability. Textured surfaces can be more abrasive than smooth surfaces, causing the tape to wear out more quickly. It is important to choose packaging tape made from a durable material, such as reinforced or heavy-duty tape. These types of tape are designed to withstand more wear and tear, providing a longer-lasting bond on textured surfaces. Furthermore, the texture of the surface can affect the appearance of the tape. As textured surfaces are not smooth, the tape may not lay flat and can create air pockets or wrinkles. This can give the package a messy or unprofessional look. To improve the appearance, it may be necessary to use extra tape or apply it in a way that smooths out any unevenness. Lastly, the removal of the tape from textured surfaces should be considered. Textured surfaces can make it more challenging to cleanly remove the tape without leaving behind any residue. To avoid damaging the surface or leaving sticky residue, it is recommended to test the tape on a small, inconspicuous area before fully applying it. If residue does occur, adhesive removers are available to safely remove any remaining residue. In conclusion, when using packaging tape on textured surfaces, it is important to choose tape specifically designed for uneven surfaces, select a durable tape that can withstand the texture, consider the appearance of the tape on the textured surface, and be cautious of any potential residue left behind when removing the tape.

- Q: How does the temperature affect packaging tape's adhesive properties?

- The temperature can have a significant impact on packaging tape's adhesive properties. In hot temperatures, the adhesive can soften, causing it to lose its stickiness and potentially result in tape failure. Conversely, in cold temperatures, the adhesive can harden and become less flexible, leading to reduced bonding strength. Therefore, it is crucial to store and use packaging tape within the recommended temperature range to ensure optimal adhesive performance.

- Q: Is packaging tape safe to use on ceramic tiles?

- Yes, packaging tape is safe to use on ceramic tiles. It adheres well to the smooth surface of the tiles and does not cause any damage or leave any residue when removed.

- Q: Is packaging tape resistant to oil or grease?

- Yes, packaging tape is generally resistant to oil or grease. Packaging tapes are designed to securely seal boxes and packages, ensuring that the contents inside are protected during transportation. These tapes are typically made of materials such as polypropylene or PVC, which have properties that make them resistant to various substances including oil and grease. This resistance helps to prevent the tape from deteriorating or losing its adhesion when it comes into contact with oils or greases commonly found in industrial or commercial settings. However, it is important to note that the level of resistance may vary depending on the specific type and quality of packaging tape used.

- Q: Can packaging tape be used for heavy-duty packaging?

- Yes, packaging tape can be used for heavy-duty packaging. There are different types of packaging tapes available in the market, including heavy-duty ones specifically designed to withstand the demands of heavy or bulky packages. These tapes are generally made with durable materials like reinforced fibers or strong adhesives that provide excellent strength and secure packaging. They are capable of holding together heavy and rigid boxes, preventing them from opening or tearing during transit. When choosing packaging tape for heavy-duty packaging, it is important to consider the weight and size of the package, as well as the specific requirements of the shipping or handling process.

Send your message to us

Custom Packaging Tape Green Masking Tape 160 Micron SGS & ISO9001 Certificate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords